16

If the pump is blocked, contact you local

dealer for technical support.

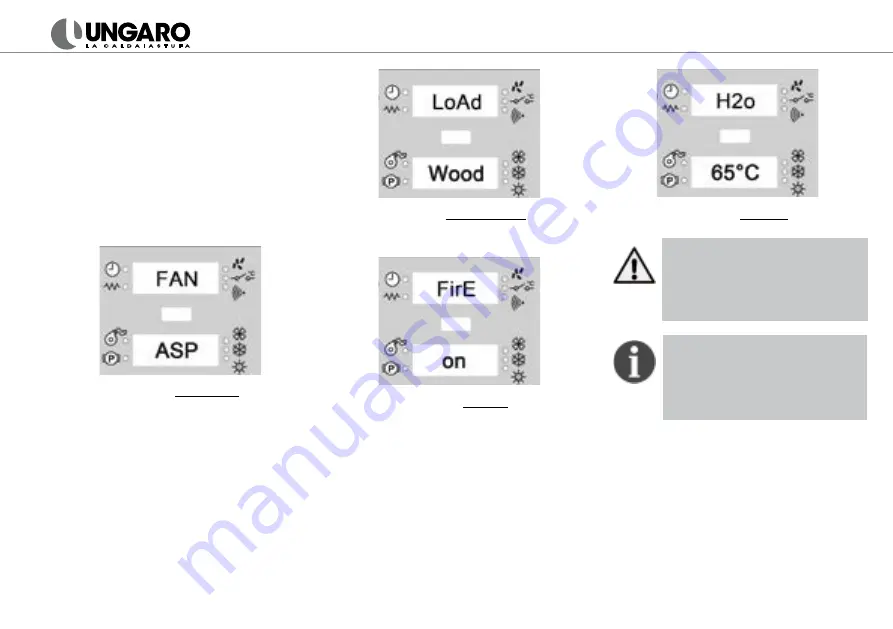

STEP 4

• Hold pressed the button

4

. On the di-

splays

D1

and

D2

will appear “

Fan

Asp

”. In this phase the thermostove

carries out the components test and

draft checking. In case of fault, may

appear the alarm codes “

No Dep

” and

“

Press H2O

”

(fig. 19)

(

see chapter 8

).

fig. 19

- Test phase

• When test phase is compleated, on the

display appears

“Load Wood”

. The

pellets start to fall in the brasier and

after a few minutes the flame strikes.

fig. 20

- Pellet loading

• The following phase is “Fire On”.

fig. 21

- Fire ON

•

The flame stabilization recognizes after

appearance of the power value on the

display

D1

.

• Normally, the lowest power necessary

for the phase “

Fire On

” is

Po6

.

• On the display

D2

is shown the water

temperature. The recommended value

is

65°C

(fig. 22)

.

fig. 22

- Set H20

Faulty thermostove and flue pipe

maintenance can fault ignition during

this phase. On the display will appe-

ar “

Pull Brac

-

No Fire

”. Clean the

thermostove, empty the burning pot

and repeat the ignition.

When the ignition phase is complea-

ted, set the power to “

Po9

”. The ro-

oms will be heated in less time and

the modulation phase starts earlier.

In this way you reduce the pellet

consumption.

5.1 Logs

ignition (Bifuel model)

Open the door of the lower combustion

chamber. Place medium size logs (max

35cm length, 5 cm diameter), not more

than 1 kilo at a time. In order to avoid so-

oting on the glass, it is important that the

log is not placed adjacent to the glass on

the product.

In the wood logs combuston chamber the

temperature is controlled by motherboard.

Summary of Contents for BiFuel en ELS34

Page 1: ...USER S MANUAL...