6

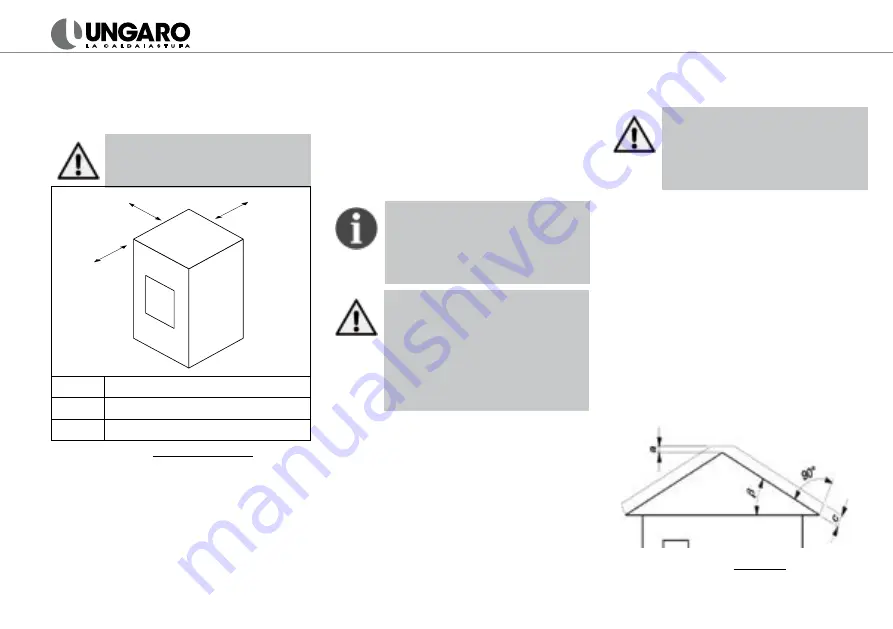

is made of flammable material, provide a

floor protection surface in compliance with

current national standards. Respect the sa-

fety clearance as shown on

fig.1

Ungaro S.r.l. will not accept any

liability in case of fire for failure to

comply with the safety clearance.

C

A

B

A

500 mm

B

500 mm

C

2000 mm

fig. 1

- Safety clearance

3.4 Flue Pipe (ref. UNI 10683)

The flue pipe must meet the following re

-

quirements:

•

Twin wall steel flue, required diame

-

ter is 100 mm round for 24 kW mo-

dels or 130 mm for 34 kW models,

regardless of external or internal in-

stallation of the duct;

• It must be resistant to heat, mecha-

nical stress, heat, combustion resi-

dues and related condensate;

• It must be installed at a safe distance

from eventual combustible materials;

• It must have draft between 11 and

15 Pa.

The proper draught conditions in the

flue is critical for the efficient wor

-

king of pellet boilers/thermostoves.

All sections of the flue must be ca

-

pable of inspection and removable to

enable periodic internal cleaning.

The boiler must be connected to a

flue pipe or a vertical duct which can

discharge the fumes at the highest

point of the building, conforming to

current national regulations. Failu-

re to comply can lead to the termi-

nation of the guarantee and of the

manufacturer’s responsibility for the

product.

3.5 Flue gasses discharge

To discharge the flue gas outside, make a

hole of an adequate size to the flue pipe.

A T-element with inspection cap and

chimney cowl

must be installed on the

flue pipe run.

Maximum two accessible 90° bends are al-

lowed on the flue pipe, each of them must

have a T-fitting with inspection cap. Maxi

-

mum permissible flue lengths are 3 meters

with an upward slope of 3%.

Flue gasses discharge on the wall is

not permitted by current regulations.

Failure to comply can lead to the ter-

mination of the guarantee and of the

manufacturer’s responsibility for the

product.

Smoke exhaust with existing flue

A chimney cleanout access door is required.

Control and periodically clean the chimney.

Chimney terminal position

For the installation of smoke exhaust

ducts consult the technical regulations UNI

10683. As shown on the

fig.2

, the terminal

of the chimney over the roof must have the

following quotes (b>10°):

- a = 500mm

- c = 1300 mm.

fig. 2

- Chimney

Summary of Contents for BiFuel en ELS34

Page 1: ...USER S MANUAL...