12

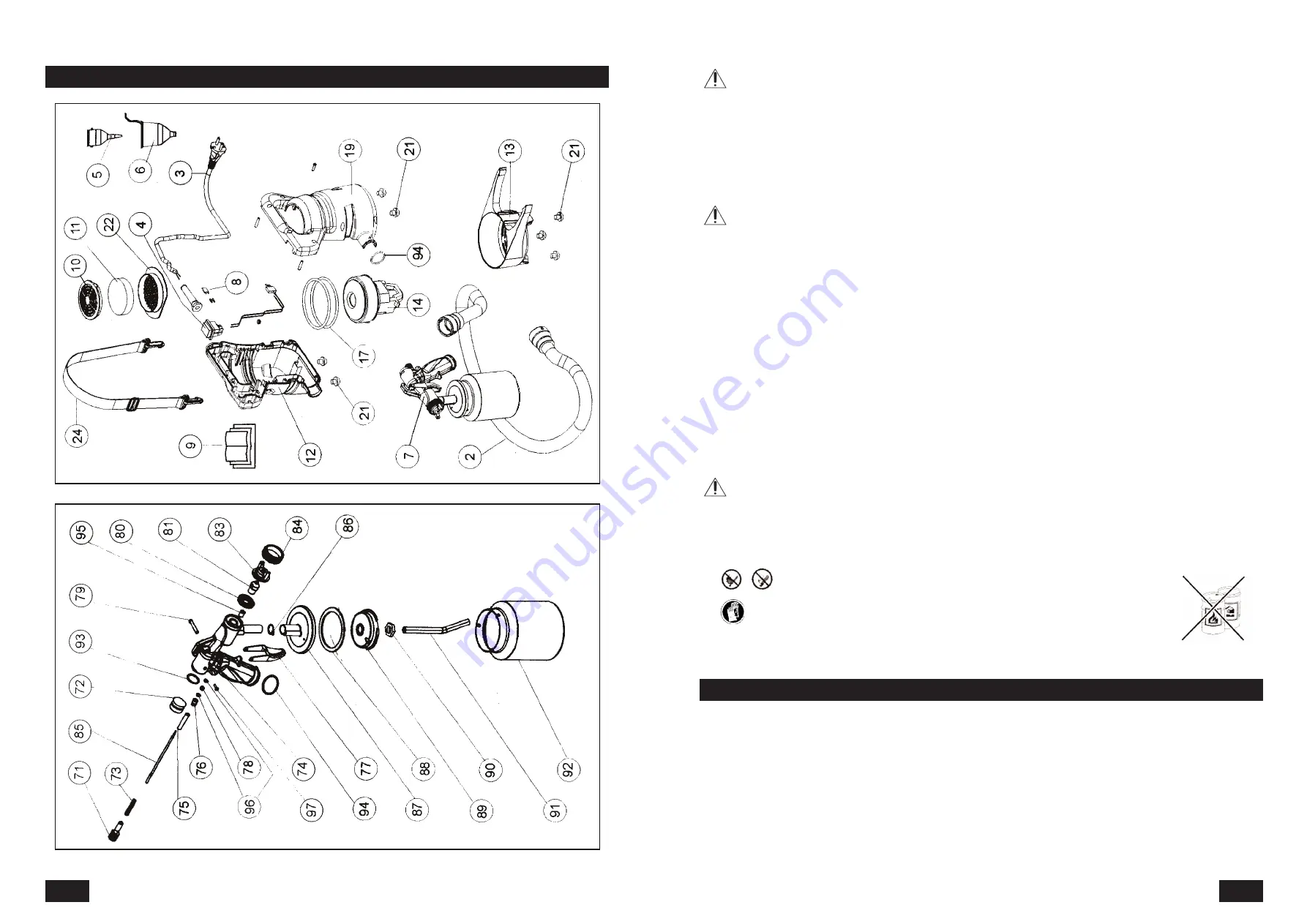

DETAILED PART DRAWING

5

Paint spraying

•

Read the specification label on the paint container carefully.

•

We recommend to wear protective mask and gloves during work and cleaning.

•

Use only in well-ventilated rooms.

•

Follow all instructions carefully. Use only products with inflammation point above 22°c.

•

Do not smoke during work and do not use device that produce heat or sparks. Paints and paint thinners

contain flammable chemicals.

Compressed air

•

Make sure no dirt can enter the inside of the machine. Keep inlet and outlet openings clean.

•

Before uncoupling compressed air piping or hose, turn off the air pressure supply. Wait until the pressure

equalizes.

•

Before starting your work, inspect all couplings and piping for leakage. If leak is found repair it immediately.

Leakage puts an extra strength on the compressor and increases the operational cost.

•

Inspect the pressure hoses and piping system regularly. If you discover damage or leak, stop working

immediately and have the damaged part changed or repaired immediately.

•

Pressure hoses must not be twisted. Observe the line on the surface of the hose that must not be twisted.

•

Pressurized hoses may not be run through structures where they may get cut or get damaged.

•

Before installing a new hose blow compressed air through it first.

•

If you have to run the hose through various structures, use bushings to protect the hose from damages.

Inspect the hose regularly.

•

Use protective caps and plugs to prevent dirt from entering the system.

•

Do not aim compressed air flow at people or animals.

Power equipment

•

Before performing any maintenance on hydraulic or air equipment, turn of the air supply and make sure to

lower the air pressure slowly. Let the pressure equalize.

•

If your machine is equipped with depressed springs, use suitable device to release them slowly and safely.

•

Do not smoke or work with an open fire during work.

•

Use personal protective gear such as gloves, goggles and respirator according to

the recommendation of the paint manufacturer.

•

Make sure no part is left inside the packaging box before throwing the packaging materials out. If so, take

it out and install it. Use the part listing for check-up and the installation drawing for guidance.

•

Unpack the multi-stage compressor and make sure that it is not damaged. Carefully inspect and organize

the documentation and accessories supplied with your machine.

ASSEMBLY