MANUAL - UG4000-6000 UPP6500E and UP6000

REVISION 2014-09

8

CLEANING SPRAY GUNS AND CUPS

•

Loosen the air cap of the spray gun two full turns.

•

Lock the trigger in the open position with the Trigger Lock Spring.

•

To prevent liquid from entering the air passgae during automatic cleaning, insert the white plas-

tic Air Passage Plug into the Spray Gun's air inlet. If the air inlet has a male threaded connector

instead of a quick connect use the knurled nut attached to the Trigger Clamp (included).

•

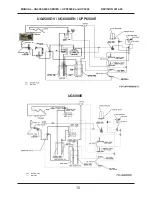

Place spray guns facing corner jets. Placement depends on

type of spray gun

. See pictures

below. Place cups onto the low spray jets and cup holders.

Note:

Gravity Feed Spray Gun:

Some customers prefer to clean the cup separate from the spray

gun.

•

Close the lid and turn the “Auto Wash Timer” knob clockwise to start cleaning. The cleaning

cycle takes about 60 seconds

•

Push and hold the "Air Rinse" button for about 3 second to air-rinse the guns.

•

Push and hold the "Clean Rinse" button for about 5 seconds to rinse guns with clean sol-

vent. This will send a pre-set amount of clean solvent (100 cc) through the jets. Wait 30 sec-

onds for the Rinse Pump to fully recharge before repeating.

The

s

olvent flow per clean-rinse cycle is limited to 100 cc to minimize consumption. This quanti-

ty is usually sufficient to clean the inside passages of the spray guns.

CLEANING PRESSURE POTS AND LIDS (UPP6500E only)

•

To clean the pressure pot and lid separately, place them one at a time over

the extended rotating spray assembly and follow the same procedures as

above.

CLEANING PAILS (UP6000 only)

•

To clean a pail, turn the INSIDE-OUTSIDE SELECTOR to “INSIDE”, place the pail over the

extended rotating spray assembly and follow the same procedures as above. Then chnnge the

SELECTOR to “OUTSIDE” and follow the cleaning procedure again.

MANUAL WASH and MANUAL CLEAN RINSE

•

For models with the Manual Wash Brush, open the lid and step on the foot pedal (left pedal on

two-pedal models). A dedicated pump delivers wash solvent through the brush.

•

For models with the Manual Rinse feature, open the lid and step on the foot pedal (right pedal

on two-pedal models). Clean solvent is delivered through the Brush or the Spigot.

S

olvent flow for clean rinsing may limited to minimize clean solvent consumption.

UG6000 SERIES

• Larger Tank size and Flexible Spigot

• For Brush cleaning, choose between wash solvent and clean solvent: use the Brush Solvent

Selector on the front of the unit.

• To vary the rate of solvent flow through the Brush, use the Brush Solvent Flow Control on the

side of the unit.

UG4000FS

• Brush Flow Control snd a Foot pedal activated Fixed Spigot.