17

MANUAL - SPRAY GUN CLEANERS - UG5000W SERIES

Revision 2019-3

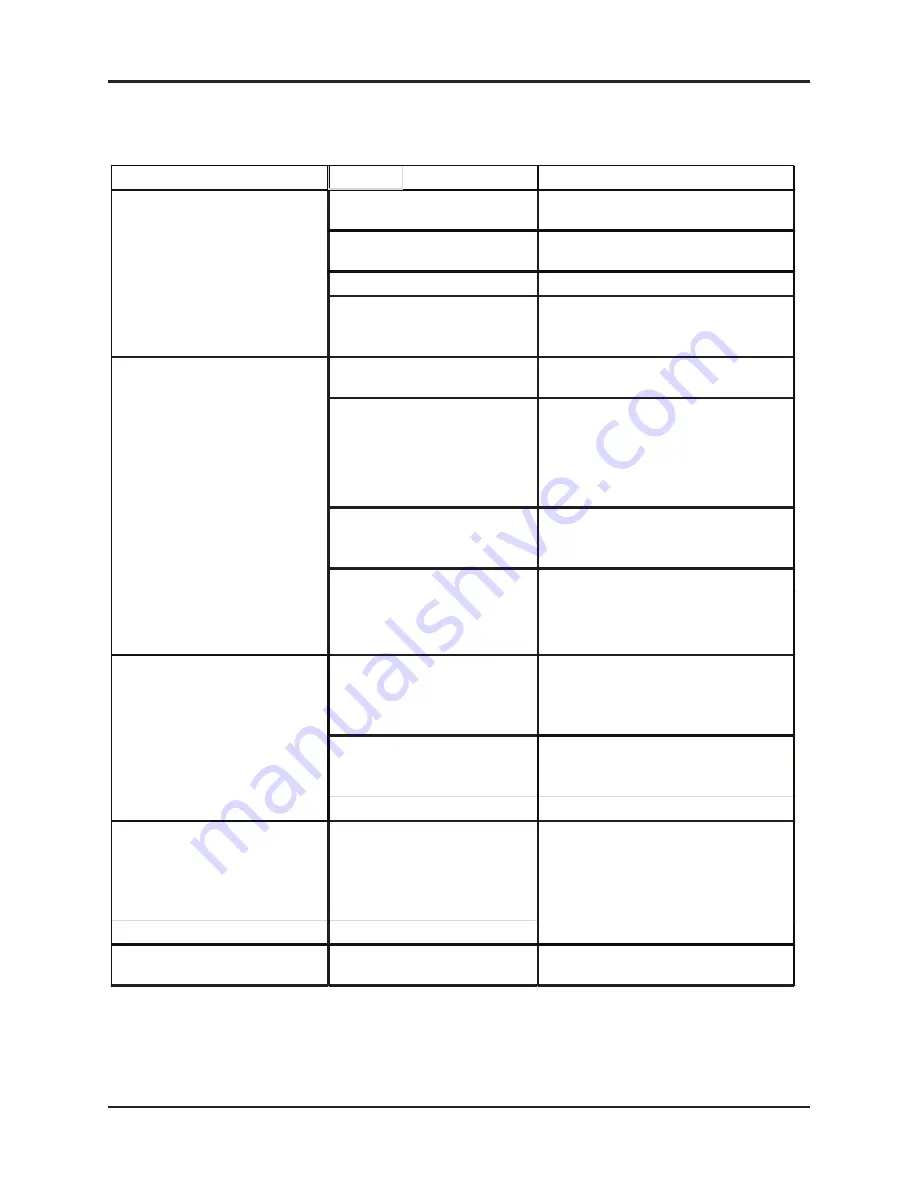

TROUBLESHOOTI

NG CHART

PROBLEM

REASON

CORRECTIVE ACTION

Drain valve closed

Open drain valve (put in vertical

position), if not already open

Liquid level too low

Check wash liquid level. Add liquid if

less than1/2 full.

Fill to 4 gal (11 L).

Debris in pump or suction and

output hose

Follow Procedure 1, "Blocked Fluid

Passage in Diaphragm pump" in the

next section.

Water or contaminants are in

air line of pump.

Passage in Diaphragm Pump" in the

next section.

Flow Control is closed.

Manual flow control is located on the

control panel on the front of the

machine. Loosen the locking nut and

rotate control to the left to increase

flow.

Liquid level too low

Check wash liquid level. Add liquid if

less than 1/2 full up to 4 gal (11 L).

Foot pedal switch not

functioning

Inspect foot switch for free travel, and

lubricate with gun oil. If switch will

not travel freely, replace with PN 155-

400BF2

Water in air line causes pump

to stall

Follow Procedure 2. "Blocked Air

Passage in Diaphragm Pump" in the

next section.

WASH PUMP DOES NOT

STOP UNLESS TIMER IS

TURNED BY HAND OR AIR IS

SHUT OFF. WASH PUMP

DOES NOT START.

Defective Timer

TIMER KNOB

SPINS BACK

WHEN TURNED

Defective Timer

Replace Timer. PN 115-200K.

Replace Timer, PN 115-200K.

WASH PUMP

MAKES

HISSING SOUND AND LIQUID

DOES NOT FLOW

BRUSH PUMP

DOES NOT

MAKE A NOISE AND LIQUID

DOES NOT FLOW WITH

PEDAL DEPRESSED

Brush is clogged with debris.

Unthread brush from hose and

operate foot pedal. If free solvent flow

is now seen, replace brush with PN

144-390S

WASH PUMP

MAKES

PUMPING SOUND BUT

LIQUID DOES NOT FLOW

FROM THE JETS

of fresh solvent. Top up clean solvent pail to 19 L. Insert the Rinse Pump into the full clean

solvent pail. Return hoses to the Wash Pail and return both pails to the cabinet.