MANUAL - SPRAY GUN CLEANERS - UG7500 SERIES

REVISION 2011-05

12

TROUBLESHOOTING PROCEDURES

PROCEDURE 1

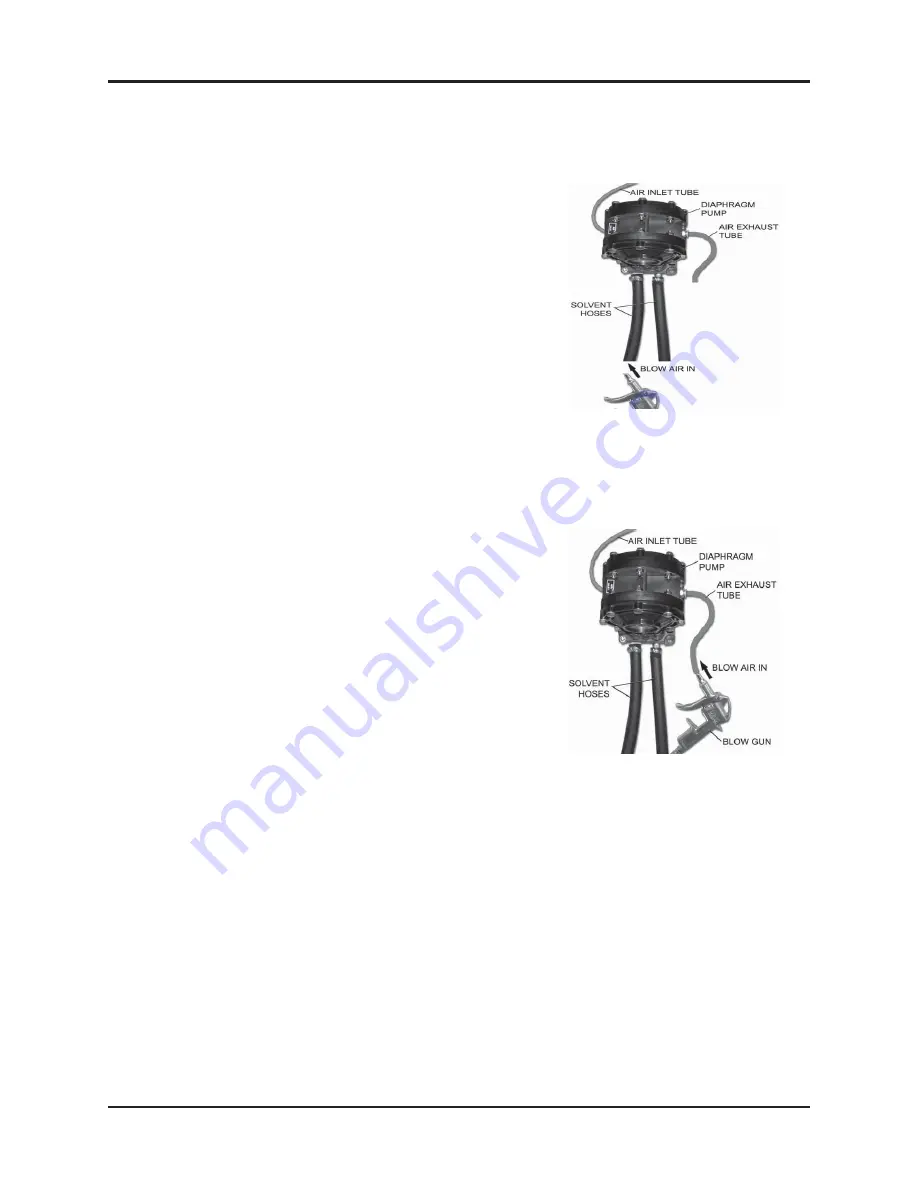

Blocked Fluid Passage In Diaphagm Pump

If the pump sounds like it is working but liquid does not flow, clear

the

fluid passage as follows:

•

Remove suction tube from the pail and blow air at 85 PSI into

the

INLET Sovent Hose (see diagram). Step on foot pedal. This

procedure may have to be repeated several times. If this pro-

cedure does not help, blow some water into the suction hose

using a spray gun, wait one minute and step on foot pedal.

This procedure may have to be repeated several times. If this

procedure does not work, the pump must be replaced.

If you need to replace the pump call your local dealer. The warran-

ty

on the diaphragm pump is two years from date of purchase.

This procedure will also clear a blockage in the fluid line for the wash gun.

PROCEDURE 2

Blocked Air Passage In Diaphragm Pump

If there is a steady hissing sound and the pump is not cycling, the spool valve has stalled due to a

blocked air passage. Follow the procedure below to clear the blockage.

• Connect a blow gun to an 85 PSI source. Locate

the

blue hose that extends from the air exhaust port of the dia-

phragm pump. Use a blow gun to blow air into the open end

of this hose. Turn timer. If the procedure is successful,

the

pump will start working. The procedure may have to be

repeated several times. If this procedure does not work,

replace the pump.

•

Cause: Contaminants in the air supply (water, oil, solid parti-

cles

etc)

•

Preventative Action: If necessary, install an Airline (Moisture)

Filter.

PROCEDURE 3

Blocked Passage in Air Line

The components in the air line are the diaphragm pump, air valve, foot pedal, 3-way ball valve and regu-

lator. See the Flow Diagram and the section: Replacement Parts.

To troubleshoot a component:

1) Disconnect the air line to the component using the quick disconnect.

2) Step on foot pedal and check for presence of positive air pressure in the air line. If there is ample

positive air pressure, replace the component.

If air pressure is absent, there is a faulty component upstream. Reconnect the air line and check the

operation of the next component upstream by following steps 1 and 2 above.