3.2 Function Selection

3.3 Compliances:

IEC 61010-1 CATIII 300V , Pollution Degree 2

IEC 61557-1, 5

IEC 61010-2-31

Caution:

1. Frequency Range for AC Voltage: 50~60Hz;

2. For AC voltage

<

60V, the reading is for reference only.

3.4 Working Voltage:

230VAC (Range: 195~253V)

3.5 Working Conditions:

Temperature: 0 ~40

Relative Humidity: 80%RH

Altitude: 2000m

3.6 Storage Conditions:

Temperature: -20 ~60

Relative Humidity: 75%RH

3.7 Dimensions:

210mm x 175mm x 90mm

3.8 Weight:

About 1,000g

3.9 Accessories

Test Lead (1.5m)---------------------1

Manual-----------------------------------1

Gallus/Tool Case----------------------1

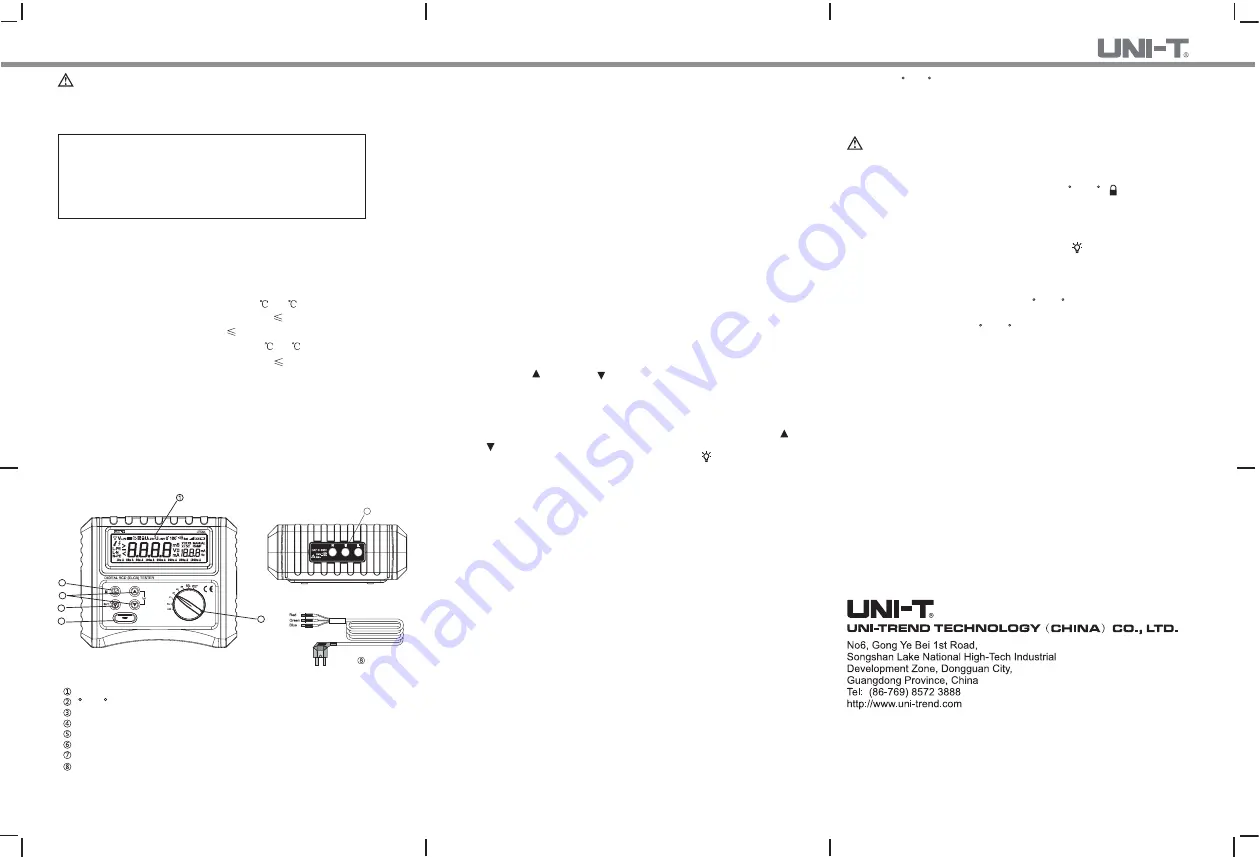

IV. Tester Description and Main Accessory

(See Figure1,2,3)

2

3

4

5

6

/

10m A 20m A 30m A 100m A 200m A 300m A 500m A 1000m A

Figure 1

Figure 2

Figure 3

7

V. RCD Test

Danger:

Do not touch any exposed earthing metal or conductor during the operation

.

(7)Test locked:

When the test lead is disconnected, long press 0 / 180 ( )button to enable

the test locked function, then connect the test lead to tested terminals, the

tests can be automatically performed.

6.3 Press 0 /180 button to set the phase angle and repeat 6.1 to determine

the fastest trip time.

6.4 Press to change the phase angle and repeat 6.1

6.5 When the tests finish, disconnect the test lead from the tested circuit

immediately.

VI. Maintenance and Repair

6.2 Maintenance

Please contact UNI-T after-sale service center or agents if the following anomaly

happens:

A.Instrument case or parts are damaged.

B.LCD displays wrongly.

C.Unexpected data shows even under normal use.

D.Buttons do not work or produce confusing display.

E.Noises arise in testing.

This manual is allowed to be alternated without prior notice.

**ENG**

X1/2------------------Non-trip test, check RCD sensitivity

X1--------------------Measure trip time

X2--------------------Measure fast trip time at I

△

n×2 trip current

X5--------------------Measure fast trip time at I

△

n×5 trip current

AUTO RAMP Test----Measure trip current

MANUAL RAMP Test--measure trip time (at setting current)

0 / 180 /Lock Button

UP/DOWN Button: Set /Adjust the Current (under MANUAL RAMP)

LIGHT/SET Button(under MANUAL RAMP)

TEST Button

Rotary Switch

Input Terminals

Test Lead

LCD

(1)Test Lead Connections

Connect three connectors of the test lead respectively to three input terminals

of the Tester: Red—L, Green—E, Blue—N, then connect another terminal of

the test lead to tested circuit (230V/50Hz power socket).

(2)Voltage Test

Set the rotary switch to V position, The tester now can measure the voltage

between L and N terminals, which should fall within 195V-253V, if not, please

check if the wiring is correct before proceeding into next step

(3)Wiring Check

Turn the rotary switch to RCD ranges and check the wiring status indicated

on LCD.

LCD Indication

Connection Status

L-N&L-PE flash Abnormal power supply or no supply to

tested circuits

L-PE&N-PE flash, L-N doesn’t The tested terminals are badly or not earthed.

L-N&N-PE flash, L-PE doesn’t Neutral terminal is disconnected

L-N,L-PE and N-PE flash Wrong wiring to tested terminals,

The tester will prohibit the tests regarding the above status, please check the

wiring and correct the connection before restart the tests.

(4) Press I

△

n UP( ) or DOWN( ) button to adjust the trip current(I

△

n) the

same as the rated trip current marked on RCD.

Default value: I

△

n 30mA 00(except MANUAL RAMP)

(5) When MANUAL RAMP is selected, the setup value“30mA” shows on lower

part of LCD, 40% of 30mA: “12mA” displays on right side, then use UP( ) or

DOWN( ) button to adjust the current within 40%~100% of the setup value at

a step of 5%; To change the setup value, long press “

” button to access

current setup, “Set” icon shows on LCD, short press to set to 10mA,20mA,

30mA, 100mA, 200mA, 300mA, 500mA or 1000mA; long press the button

to exit the setup.

(6) Taking RCD Tests

6.1 Set the rotary switch to test parameters

● Non-Tripping ×1/2: Max. trip time up to 2000ms

● Tripping ×1: 10/20/30/100/200/300mA,: Max. trip time up to 2000ms

500/1000mA: Max. trip time up to 200ms

● Fast Tripping ×2 : Max. trip time up to 200ms

● Fast Tripping ×5 : Max. trip time up to 200ms

● AUTO RAMP Test: 40%~110% of rated trip current(I

△

n), Max. trip time up

to 300ms.

● MANUAL RAMP Test: Max. trip time up to 300ms.

6.2 Press TEST button

● Non-Tripping ×1/2-----The RCD should not trip.

● Tripping ×1: ---------The RCD should trip.

● Fast Tripping ×2 : -------- The RCD should trip.

● Fast Tripping ×5: ---------- The RCD should trip.

● AUTO Ramp Test: --------The RCD should trip, and trip time and trip current

are displayed simultaneously.

● MANUAL RAMP Test-------The RCD should trip.

(8) Backlight:

when testing on dimly lighted sites, press LIGHT(

) to turn on /off the

backlight. Under MANUAL RAMP mode, press the button momentarily to turn

on/off the backlight, or long press to access I

△

n setup.

(9) Auto Power Off:

To disable the function, press and hold 0 / 180 button while turning on the

instrument, LCD will show “APO OFF” icon; the Tester usually defaults at

APO ON status(no pressing 0 / 180 button).

6.1 Cleaning the Casing:

Do not clean the instrument casing with any corrosive agents such alcohol or

solvent that may damage the display. Clean it with dry soft cloth and protect

the instrument from any moisture.

P/N:110401104490X DATE:2018.06.26 REV.2