10

- Remove the inner tube if the tyre has one.

- The lower edge of the tyre is removed from the rim without changing the wheel or mounting head position.

3

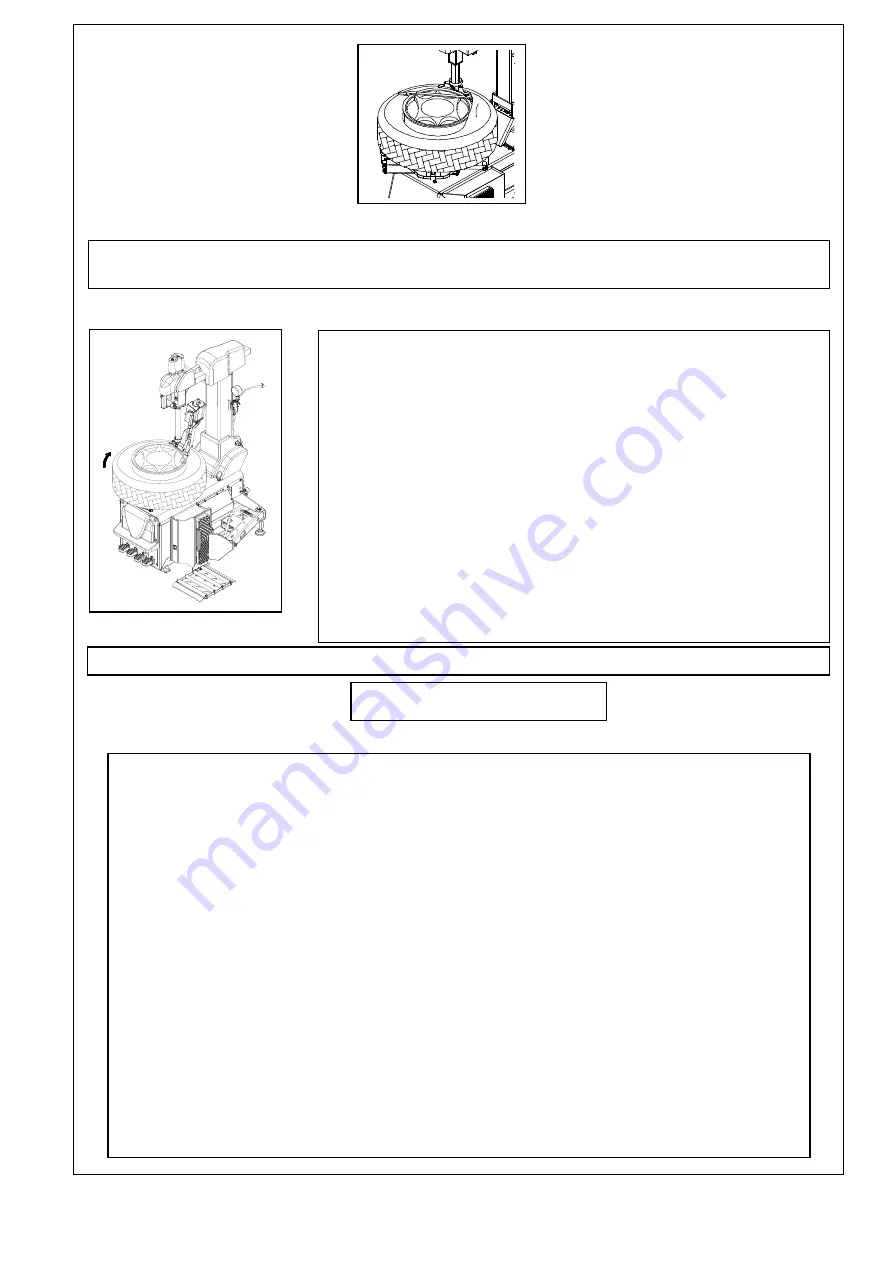

– TYRE MOUNTING

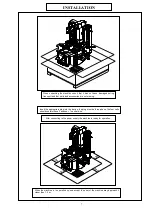

Use the pedal to tilt the column back.

Use the pedal to open the table jaws.

Place the rim on the assembly table.

Check that the jaws of the jaws firmly clamp the edge of the rim.

Move the pedal to the up position - the column will return to the vertical

Lay the tyre on the rim.

By extending the bolt to the appropriate distance and pressing the tip of the vertical bolt,

make the working head rest on the edge of the rim inside the tyre.

Place the tyre foot on the bead fin and press it under the head.

Pressing the side of the tyre with your hand in the place where its edge sticks out over the

edge of the rim, cause it to jam and hold with your hand.

While depressing the pedal turn the table clockwise placing the edge of the tyre in the

groove of the rim until the lower tyre edge is placed on the rim.

In case of any abnormalities while installing the tyre such as a jam, release the pedal and

then lift it with your foot upwards.

The table will then turn to the left and release the jammed tyre.

Fit the inner tube.

Place the top edge of the tyre on the rim in the same way as for the bottom edge.

DURING MOUNTING/DEMOUNTING WHEN THE TYRE SPLINKS, HOLD THE PEDAL UP AND ADJUST THE TYRE.

MAINTENANCE

UNI-TROL is not responsible for claims resulting from the use of non-original parts or accessories.

Before carrying out any adjustments or maintenance to the machine disconnect the power supply and check that all moving

parts are properly secured.

Do not disassemble or modify any part of the device. This does not apply to servicing.

Check that the jaws move freely daily. Contamination accumulated during the operation of the machine may significantly

deteriorate the sliding of the jaws, thus creating a hazard for the user.

Check on an ongoing basis whether the table jaws and the sliders move freely. Contamination accumulated during the

operation of the machine may significantly deteriorate its sliding, limiting its wear and creating a hazard to the user.

Therefore if necessary wash the rails and bolts with a petroleum solvent and then moisten with thin oil or silicone preparation.

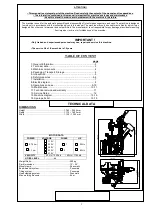

Monthly check:

Clean (gasoline only) and lubricate the horizontal and vertical slide in the right places.

Check the oil level in the grease gun and, if necessary, add HL 32 (hydraulic) or a parametric equivalent of a different

manufacturer.

Keep the workplace clean. Do not clean the device with pressurized water. Avoid generating dust when cleaning.

The assembly table is powered by an electric motor via a worm gear lubricated with Shell OMALA oil 680 or a parametric

equivalent of a different manufacturer's oil. After 4,000 hours of work (after deduction of breaks), the gear must be cleaned and

the oil changed.

Periodically you should also remove the oil from the inside of the housing box. Exhalation of the lubricated air, as in all devices

of this type, takes place inside the housing, which causes the oil to settle on its internal surfaces, and as a result to leak it.