18

SPARE PARS LIST

Number

CODE

DESCRIPTION

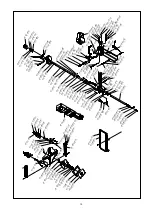

148

01 0031 139

BEAD BREAKER PEDAL PULLING SPRING

149

01 0122 010

SETSCREW

150

11 12 010

PLASTIC PEDAL

151

01 0072 035

BOLT

152

01 0072 020

BOLT

153

91 05 012

DISTANCE GAUGE MILE

154

91 05 006

POWER SWITCH SPRING CAP METAL SHEET

155

72 02 002

BOLT

156

91 05 013

CAP CONNECTION METAL

157

01 0081 016

BOLT

158

91 05 009

POWER SWITCH LOCATION MOVEMENT METAL SHEET

159

01 0130 012-018-0.5

RAYNEL WASHER

160

91 05 014

POWER SWITCH METAL SHEET SLIDING METAL

161

91 05 005

POWER SWITCH SPRING BEARING METAL

162

01 0031 135

SINGLE AND DOUBLE CYCLE POWER SWITCH SPRING

163

59 07 013

POWER SWITCH CAP OPERATION PICTURE

164

00 01 0001

POWER SWITCH LATCH

165

01 0200 23

POWER SWITCH

166

01 0031 134

PEDAL PULLING SPRING

167

01 0072 055

BOLT

168

01 0072 040

BOLT

169

01 0031 29

GAUGE MILE PRESS SPRING

170

01 0117 008

NUT

171

01 0073 055

BOLT

172

01 0112 10

WASHER

173

91 05 008

MOVEMENT GUIDE METAL SHEET GROUP

174

01 0115 005

NUT

175

01 0071 010

BOLT

176

01 0072 010

BOLT

177

01 0139 012

MILE SEGMENT

178

01 0117 006

NUT

179

01 0112 06

WASHER

180

01 0550 13

PEDAL MOVEMENT GUIDE

181

01 0105 016

METAL SHEET SCREW

182

01 0123 025

SETSCREW

183

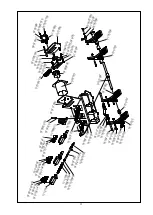

01 0014 56 PC

RECORD

184

01 0014 157

RECORD

185

01 0014 55 PC

RECORD

186

01 0024 090-2.5

O-RING

187

01 0024 065-3

O-RING

188

00 01 0028

AIR DISTRIBUTOR EXIT INJECTION

189

00 01 0027

AIR DISTRIBUTOR ENTER INJECTION

190

11 16 001

RUBBER HEAD

191

11 16 002

CYLINDER

192

01 0360 060-045-10

NUT-RING

193

47 28 000

BEAD BREAKER ARM GROUP

194

47 29 000

CRESCENT GROUP

195

01 0117 012

NUT

196

01 0064 100 12.9

BOLT

197

01 0114 43

BAKALITE NUT

198

80 11 002

TYRE REEL BODY METAL SHEET

199

80 11 003

TYRE REEL BODY GROUP

200

80 11 004

TYRE REEL CONNECTION METAL SHEET

201

80 08 001

CYLINDER

202

80 08 002

CYLINDER MAIN MILE

203

59 06 004

CYLINDER BACK CAP

204

59 06 003

CYLINDER FRONT CAP

205

01 0024 022-2

O-RING

206

01 0023 016

DUST SEAL

207

01 0021 012-20x5.5

NUT-RING

208

01 0014 62 NSE

RECORD

209

80 08 003

RUBBER HEAD

210

91 00 021

HOSE DIRECTION SHEET METAL

211

01 0073 016

BOLT

212

01 0024 014-3

O-RING

213

47 23 008-F

CROSS TOP SHEET METAL

214

47 23 008-D

CROSS BOTTOM SHEET METAL

215

47 23 008-E

SHEET BAR

216

91 05 026

PIN

217

01 0072 030

OBOLT

218

91 05 019

BUSHER

219

59 07 014

PULL GROUP

220

01 0115 008-04

NUT

221

59 07 009

SHAFT

222

01 0152 1-4 EK

VALVE