18

6.1.7 Balancer drive.

- Manual start.

Press

.

If we don’t close the hood the display shows CASE. The drive starts when hood is

closed and key

pressed. Display shows pictogram of cycle start. When the display shows

measuring result and the spindle stops the cycle is finish.

- Automatic start.

By closing the hood. To activate this function press and hold

simultaneously pressing

Display shows

[ AUTO ON] .

Pressing both keys again

return to manual mode. Display shows

[AUTO OFF].

6.2 Wheel balancing

Balancing of every wheel consists in determining the volume of imbalance expressed in grams for

inner and outer correction plane and localising position of imbalance on the wheel. In order to

clearly identify the volume of imbalance, it is necessary to enter the following data into the machine

memory: WIDTH, DIAMETER, DISTANCE

— corresponding to geometrical dimensions of the

wheel to be balanced, select balancing programme (manner and positions of correction weights)

and enter the value of accuracy.

If one wants to balance the wheel whose parameters were previously saved in the memory M

of the computer, then it is enough to press button

or

to enter data on this wheel.

Upon entering the measuring setpoints, the wheel should be brought up to speed of at least

95 rpm. The measuring cycle is conducted with no interference on the side of the operator

and is completed by displaying the value of imbalance in the indicator screen.

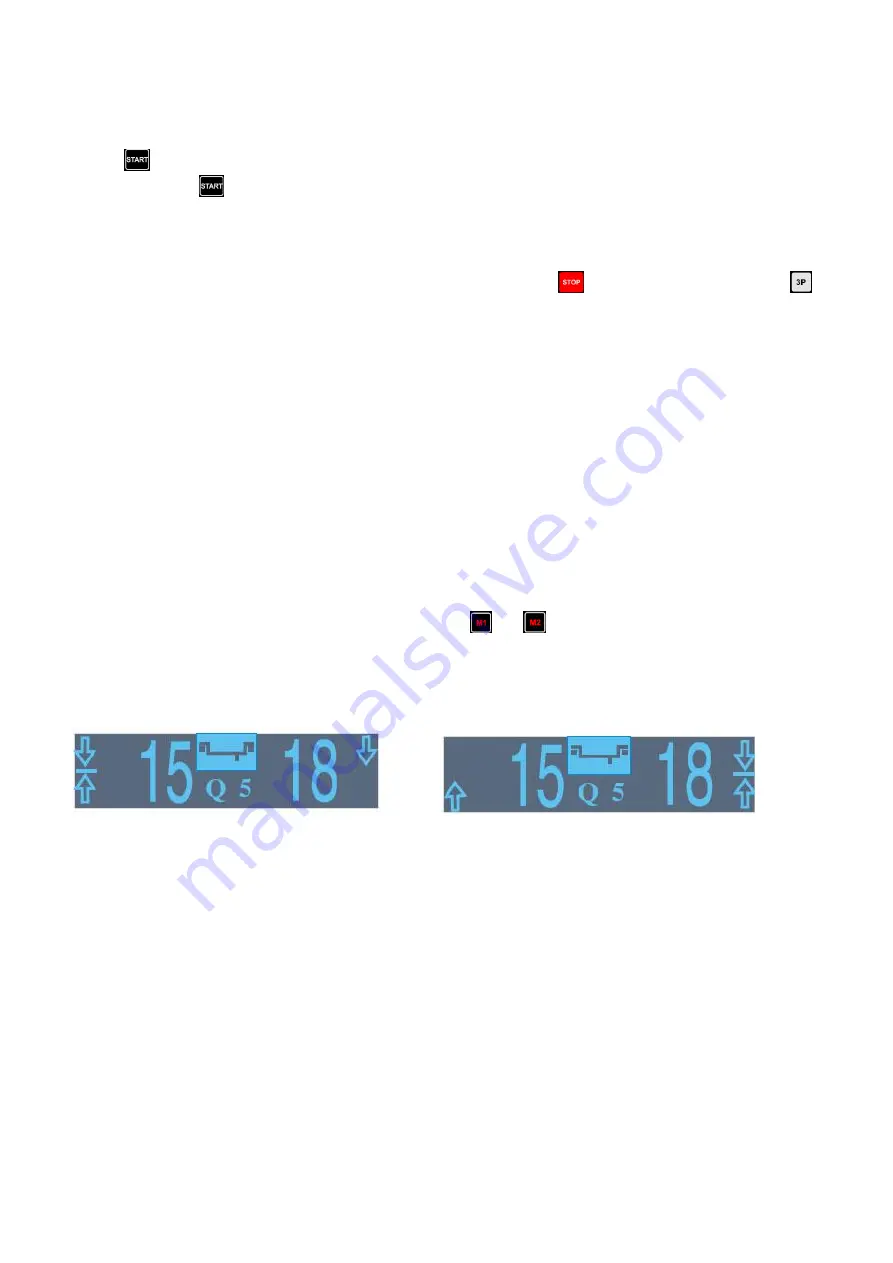

The indicator screen displayed exemplary values of imbalance:

- 15 g

— applicable to inner left correction plane

- 18 g

— applicable to outer right correction plane

spinning the wheel slowly, at each revolution one may hear sound signals slightly different from

one another.

They occur in such wheel positions for which the arrows defining the position of imbalance are

directed towards one another.

The value of 15 g displayed in the indicator screen means that the weight of 15 g should be

attached on the inner edge of the rim in order to balance the imbalance. Watch the arrows while

spinning the wheel in any direction. The sound signal shall be heard and arrows directed towards

one another only for one position of the wheel against any reference point. For this wheel position,

the weight of 15 g should be attached at the topmost point on the inner edge of the rim. The position

of attaching weight of 18 g (20 g) on the outer correction plane shall be searched the same way