24

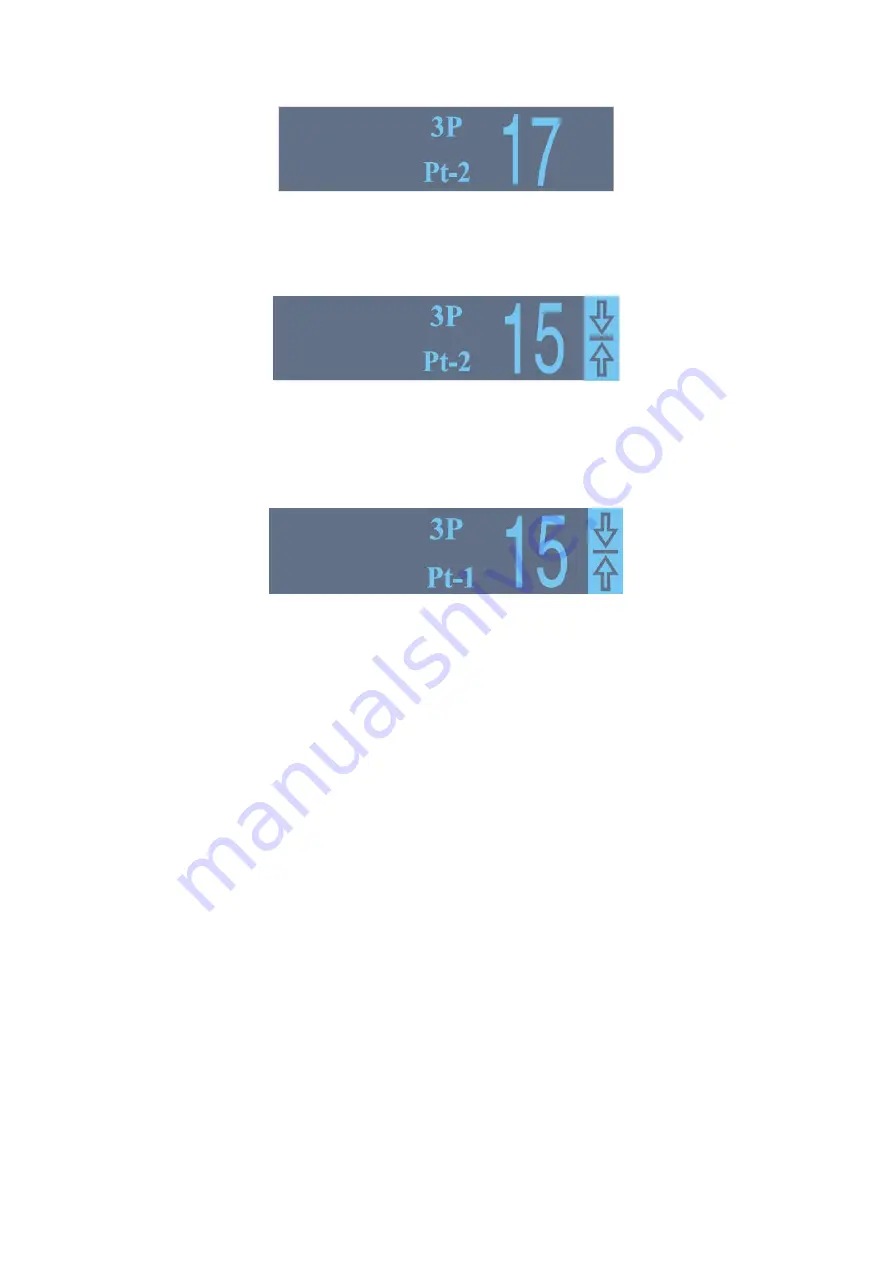

3.4 Spin the wheel to the right to the position defined in point 3.1 until the spoke

where weight can be placed. To accept this position press (+) .

This is a point where correcting weight of 15 g should be placed.

3.5 Spin the wheel to the left until the place defined in point 3.3. Sound signal

indicates the right wheel position, display shows the value of imbalance, arrows

directed towards each other.

This is a point where correcting weight of 15 g should be placed

3.6. After the weights have been placed exit the programme 3P by pressing (STOP).

Start measuring cycle and check whether the wheel has been balanced correctly.

6.3 CALIBRATION WITH CALIBRATING DEVICE

The wheel balancer is equipped with a self-calibration system enabling the user to

calibrate the machine himself. Calibration shall be performed in the case of suspicion

of incorrect indications displayed by the machine (caused by aging of electronic

components, impact of temperature, vibrations in transport, etc.). Calibration of the

wheel balancer should be carried out in the following way:

1. Automatically inserted calilbrating parameters.

- off-set - 54,0

- diameter - 14,6

- width - 4,0

2. Screw calibrating device as it shown on Fig. 10 and close the hood.