17

II. MACHINE PREPARATION FOR FERTILISER DISTRIBUTION

1.0. Loading of the fertiliser distributor

The height of the rear upper edge of the container does not exceed 1.24 m. Do not

load the fertiliser in the amount exceeding the container capacity specified by the

manufacturer in specifications

NOTE:

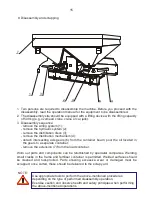

Inside the container, at the rear wall, there is a graduated capacity gauge. Avoid

loading fertilisers that are clumped, contaminated with foreign matter or wet and prone

to smearing, as this may reduce the quality of the fertiliser distribution operation or

even prevent it.

During loading, the relieving screens inside the container must be lowered, mounted

in their holders and secured with screws and nuts.

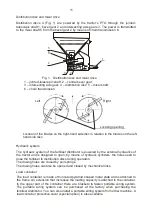

Distribution dose adjustment

The volume of the fertiliser distributed over a given area depends on the following:

- the size of the slot through which the fertiliser is fed from the container to the

distributor’s discs;

- the speed of the unit;

- width of the distribution zone.

At the back of the fertiliser distributor, above each of the distribution discs, there is a

movable lever connected with the adjustment damper at the bottom of the container.

The degree of opening of the slot is determined by the scale along which the lever can

be moved.

In order for an identical volume of fertiliser to be distributed through both discs,

make

sure both levers are positioned identically during the machine operation

.

Once

the fertiliser distribution has been adjusted, secure the positioning of the lever with the

knob.

Both slots are opened (operation) and closed (u-turns and transport) with the lever

from the tractor.

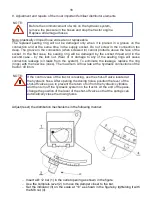

Dose adjustment in a suspended machine

is done with the drive switched off

and

closed dampers. Adjust the settings of the dampers with the lever in the following

order:

- close the dampers;

- loosen the pressure nut (a bakelite knob);

- set the indicator in the correct position on the graduated scale;

- tighten the pressure nut.

1.1. Explanation of symbols used

The PTO speed is usually 540 rpm. Possible variations are given in the distribution

data table.

Exceeding the permissible load capacity may damage the machine and

cause a risk of accident at work.

The fertiliser distributor can be loaded only after it has been

coupled with the three-point linkage of the tractor.

Summary of Contents for MX

Page 3: ......

Page 43: ...40 5 4 2 3 1 Fig 6 Fig 7...