4

6

General Safety Rules

Tool Use and Care

1. Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to

loss of control.

2 . Do not force tool. Use the correct tool for your application. The correct tool will do

the job better and

safer at the rate in which it is designed.

3.

Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

4.

Disconnect the plug from the power source before making any adjustments, chang

-

ing accessories, or storing the tool. Such preventive safety measures reduce the risk of

starting the tool accidentally.

5.

Store idle tools out of reach of children and other untrained persons. Tools are dan-

gerous in the hands of untrained users.

6.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control.

7.

Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced

before

using. Many accidents are caused by poorly maintained tools.

8.

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

9.

Always use safety chain. Mounting can release.

SERVICE

1.

Tools service must be performed only by qualified repair personnel. Service or

main

-

tenance performed by unqualified personnel could result in a risk of injury.

2.

When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Summary of Contents for CMD400

Page 2: ...2...

Page 14: ...14 s Wiring Diagram...

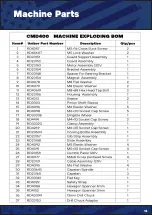

Page 15: ...15 s Machine Parts...

Page 16: ...16 s Machine Parts...

Page 17: ...17 s Motor Gearbox Parts...

Page 18: ...18 s Motor Gearbox Parts...

Page 23: ...23 s Cutting Speed Selection...

Page 25: ...25 s Extra...

Page 26: ...26 s Extra...

Page 27: ...27 s Extra...

Page 28: ...28 s Extra...

Page 29: ...29 s Extra...

Page 30: ...30 s Extra...

Page 31: ...32 WWW UNIBORUSA COM This machine is CSA approved...