Unibor CR35 Manual

Original instructions

Mar 2020

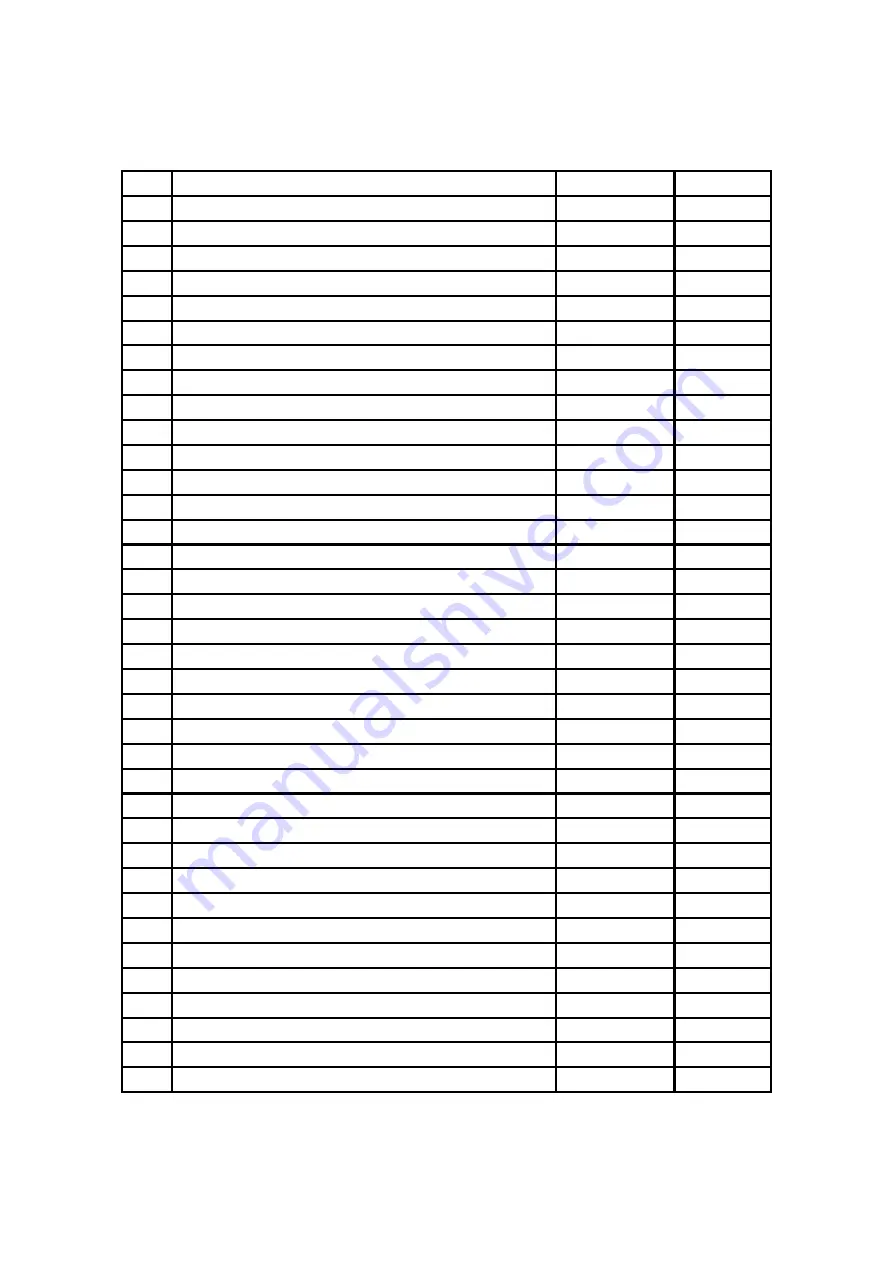

13

NO.

PART NAME

PART NO.

QTY.

1

CARBON BRUSH ASSY. 6.3X10X18

EBD002

2

2

BRUSH HOLDER ASSY.

EBD001

2

3

SCREW M4 X12

EBD003

4

4

SPRING WASHER M4

EBD004

4

5

PHILIPS HEAD SELF-TAP SCREW 4.8X45

EBD005

4

6

BACK COVER

EBD006

1

7

FIELD COIL CASING

EBD007

1

8

FIELD COIL ASSY 110V

EBD008-A

1

FIELD COIL ASSY 230V

EBD008-B

1

9

PHILIPS HEAD SELF-TAP SCREW 3.9X60

EBD009

2

10

BAFFE

EBD010

1

11

O RING

EBD011

1

13

DUST WASHER

EBD012

1

12,20

BALL BEARING (8-22-7) 608 2Z

UDC022

3

14

ARMATURE ASSY 110V

EBD013-A

1

ARMATURE ASSY 230V

EBD013-B

1

15

CIRCLIP 28MM X 1.2 B TYPE

EBD014

1

16

BALL BEARING (12-28-8)6001 2Z

UDC023

1

17

GEAR CASE COVER

EBD015

1

18

CIRCLIP 10MM X 1 A TYPE

EBD016

1

19

GASKET

EBD017

1

21

INTER SHAFT ASSY.

EBD018

1

24

SPINDLE GEAR

EBD019

1

25

BALL BEARING (17-35-10) 6003 2RS

UDC004

1

26

OIL SEAL 20-30-7 B TYPE

EBD020

2

27

GEAR CASE

EBD021

1

28

PHILIPS HEAD SELF-TAP SCREW 4.8 X 60

EBD022

4

29

BALL BEARING 6904 2RS

EBD025

1

30

ARBOR BODY.

EBD023

1

31

ARBOR SPRING

EBD026

1

32

ARBOR EJECTION PLUG

EBD027

1

33

ARBOR WASHER

EBD028

1

34

ARBOR RUBBER WASHER

EBD029

1

35

ARBOR CIRCLIP

EBD030

1

36

CARBON BRUSH WASHER

EBD031

2

37

CARBON BRUSH FIXING SCREW

EBD032

2