10

s

Operational Instructions

Keep the inside of the cutter clear of swarf. It restricts the operating depth of the cutter.

• Ensure that the coolant bottle contains sufficient cutting oil to complete the required operating

duration. Refill as required.

• Occasionally depress the pilot to ensure cutting fluid is being correctly metered.

• To start the machine, follow the control panel operation instructions.

• ALWAYS switch off the motor by depressing the MOTOR stop button. DO NOT switch off the motor

by depressing the MAGNET switch.

• Apply light pressure when commencing the cut of a hole until the cutter is introduced into the work

surface. Pressure can then be increased sufficiently to load the motor. Excessive pressure is

undesirable, it does not increase the speed of penetration and will cause the safety overload protection

device to stop the motor, (the motor can be restarted by operating the motor start button), and may

cause excessive heat which may result in inconsistent slug ejection

• Always ensure that the slug has been ejected from the previous hole before commencing to cut the

next.

• If the slug sticks in the cutter, move the machine to a flat surface, switch on the magnet and gently

bring the cutter down to make contact with the surface. This will usually straighten a cocked slug and

allow it to eject normally.

• Apply a small amount of light oil lubricant regularly to the slide and arbor support bearing.

• Cutter breakage is usually caused by insecure anchorage, a loosely fitting slide or a worn bearing in

the arbor support. (Refer to routine maintenance instructions).

• Only use approved cutting fluid do not use water diluted cutting oil.

Summary of Contents for E4000 Perm

Page 2: ...2...

Page 11: ...11 s Control Panel...

Page 16: ...16 s Wiring Diagram...

Page 17: ...17 s Machine Parts...

Page 18: ...18 s Machine Parts...

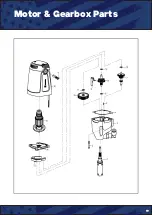

Page 19: ...19 s Motor Gearbox Parts...

Page 20: ...20 s Motor Gearbox Parts...

Page 25: ...25 s Cutting Speed Selection...

Page 27: ...26 s Extra...

Page 28: ...27 s Extra...

Page 29: ...28 s Extra...

Page 30: ...29 s Extra...

Page 31: ...30 s Extra...

Page 32: ...31 s Extra...

Page 33: ...32 WWW UNIBORUSA COM This machine is CSA approved...