Using the machine

Please Note:

For best results spray guns should be cleaned as soon as

possible after use.

WARNING:

• THE LID IS LOCKED DURING OPERATION FOR YOUR SAFETY

• THE LOCK MUST NOT BE REMOVED

• TO UNLOCK SWITCH OFF THE MACHINE

Any paint left in cup/pot should be emptied into a waste container or stored for

future use.

Place paint cup/pot into machine over the single square nozzle jets.

The air cap of the spray gun can either be loosened or removed completely and

put into machine.

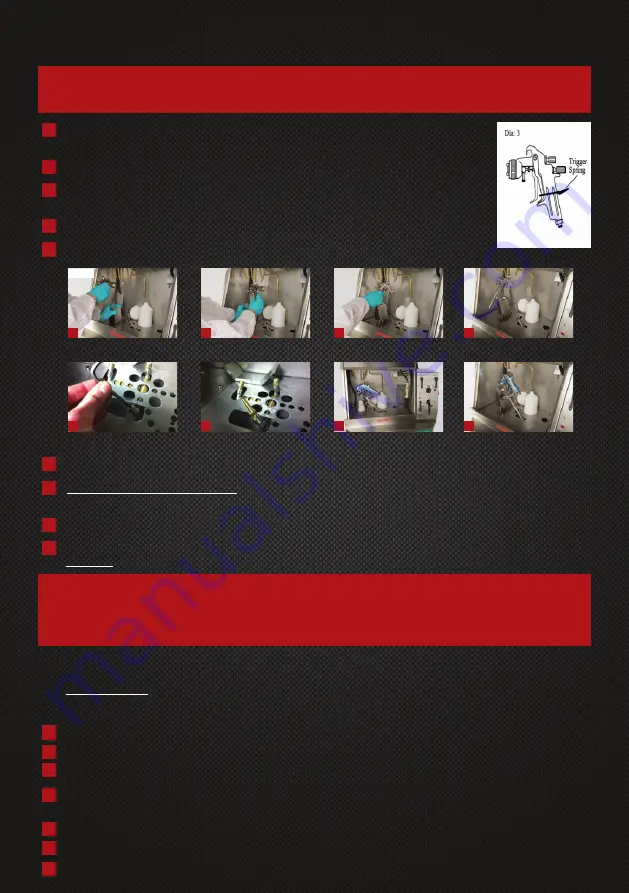

Fit the trigger clip to trigger of spray gun. See Diagram 3.

Put spray gun into machine. See Diagram 4.

1

Close lid.

UGC4006 AND UGC5006 ONLY

Ensure mode valve control lever is in the automatic position (horizontal).

Turn timer knob clockwise (The machine will run automatically for approximately 4 minutes).

Upon completion open the lid and remove the spray guns from the machine. We advise that you

DO NOT

store the spray guns in the machine.

MANUAL WASH/ CLEAN RINSE

UGC4006 and UGC5006.

For UGC2006M Manual Wash and Clean Rinse begin this process at step three.

MANUAL WASH

Turn Mode Control Valve on the front of machine to Manual Mode.

Open lid of machine.

Turn Manual Wash lever to the ‘ON’ Position and clean solvent will flow from central block and

washing brush

Proceed to wash spray gun manually.

CLEAN RINSE

Repeat steps one and two listed above

Turn Clean Rinse lever to the ‘ON’ Position and clean water will flow from central block.

Rinse the spray gun.

6

7

8

9

1

2

3

4

1

2

3

2

3

4

5

1

Push down the bracket

2

Locate the spray gun

3

Release the bracket locking the

spray gun into position

4

Gravity Fed Spray Gun

1

Remove the spray blank

2

Place the nozzle provided in the

fitting

3

Position the suction fed gun

shown the the picture

4

Suction Fed Spray Gun

Dia.4