17

Instructions for the installer

•

Mark the 3 holes with the wall bracket, using a spirit level.

•

Install the wall bracket with the 3 screws

•

With 2 people, lift the boiler by holding it by its back and by

the transport rail and install it on the wall bracket

•

The boiler can be moved sideways to get the correct posi-

tion.

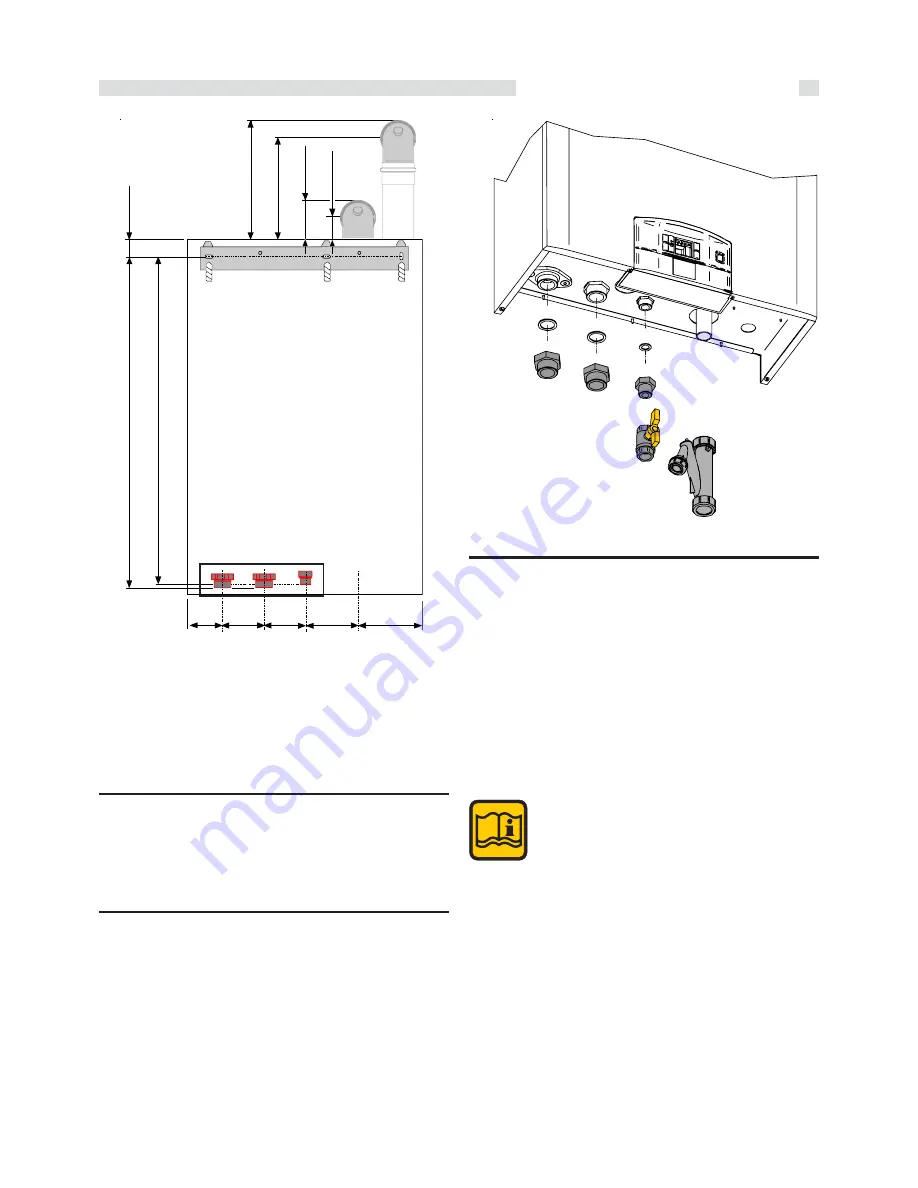

3.6 - CONNECTIONS

A)

Thread Adapter Kit NPT/gas

M

=

CH system flow

1’’¼

R

=

CH system return

1’’¼

G

= Gas Ball Valve

¾”

RG = Gas Adaptor ¾‘‘

S

= Condensate Drain

S

G

R

M

RG

3.7 -

INSTALLATION ON EXISTING

HEATING SYSTEMS

- The circulation pump’s output, the head and flow direction

are suitable.

- The gas feeding supply pipe and the eventual tank are

constructed according to the regulations in force.

- The expansion vessels assure the total absorption of the

dilatation of the fluid contained in the system.

- The system has been cleaned of impurities and lime scale.

Boiler system flushing

(Not Boiler heat exchanger)

When replacing an existing boiler the heating

system should be flushed with the old boiler in

place before the new boiler is added to the sy-

stem. If the old boiler has already been removed a bypass

must be piped in when the new boiler is installed in order

to facilitate the flushing of the system.

The boiler must be valved off from the system, while the

system is flushed.

No system cleaner should ever enter the boiler heat

exchanger because of its caustic nature it could damage

the heat exchanger.

When the appliance is installed on existing systems, ensure

yourself that:

- The flue outlet pipe is suitable for condensing boilers, for

the temperature of the products of combustion, calculated

and manufactured according to the regulations in force. It

must be installed as much as possible in a straight line,

R

M

G

S

3.3’’

(85 mm)

4.3’’

(110 mm)

4.3’’

(110 mm)

5.2’’

(132 mm)

7.0’’

(177 mm)

33

.7

’’

(8

5

6

m

m

)

34.

1’

’

(8

65.

5 m

m

)

1.

8’

’

(4

.5

m

m

)

12.

3

’’

(3

1

1

,5

m

m

)

10

.4

’’

(265

m

m

)

4.

1

’’

(1

0

3

mm)

2.

2

’’

(5

6

.5

mm

)

0,5’’

(12 mm)

0,5’’

(12 mm)

0,5’’

(12 mm)

A