22

Instructions for the installer

3.12 - WORKING PRESSURE

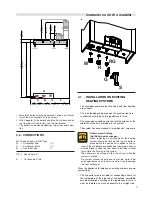

The boiler’s maximum allowable working pressure is set at

92 psa (634 kPa); whilst the minimum pressure is pre-

charged to 7,3 psa (50 kPa).

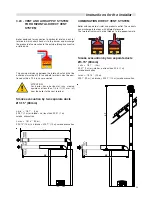

3.11 -

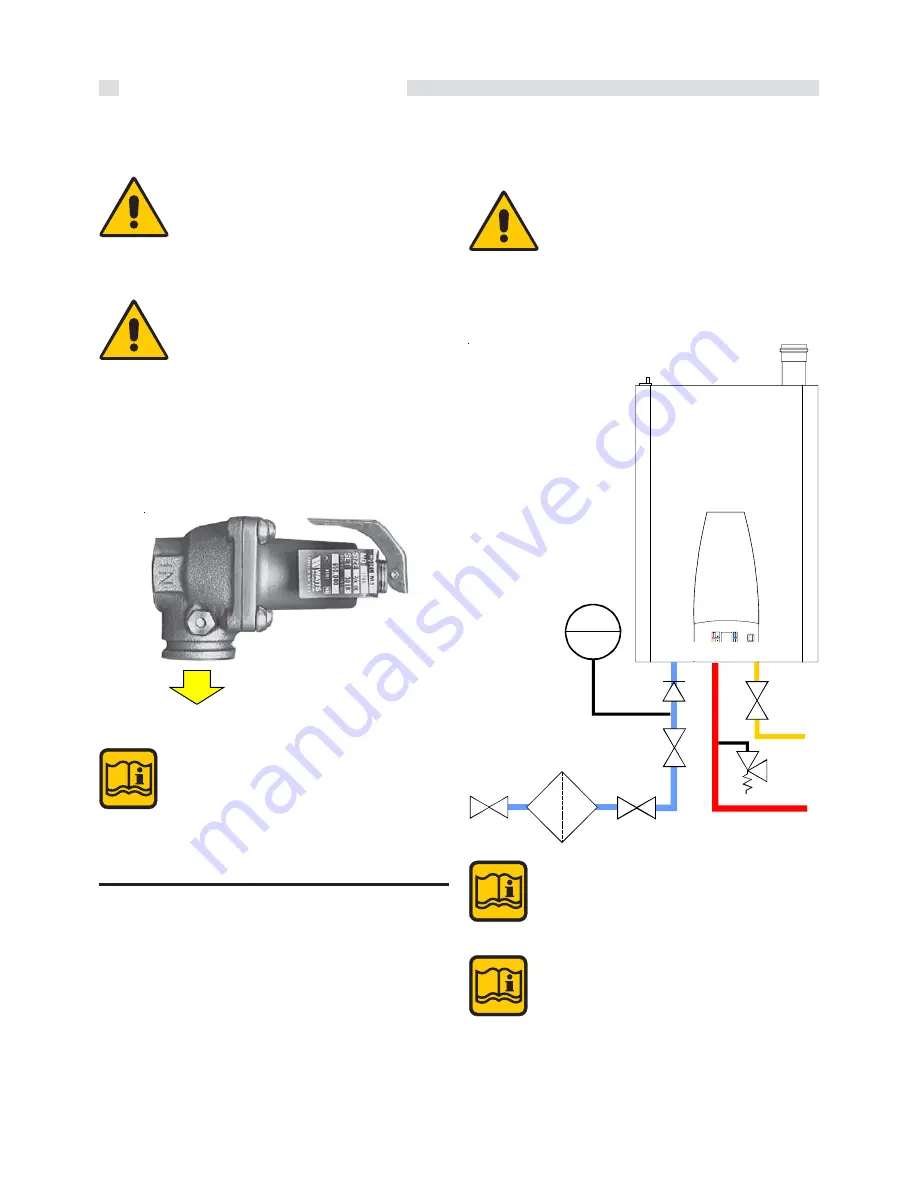

PRESSURE RELIEF VALVE DRAIN

PIPE

WARNING!

Please remember that it is forbidden to

interpose, between the boiler and the

pressure relief valve, any type of cutting-off

device. Moreover it is recommended to use

cutting-off valves which do not exceed the

maximum allowable operating pressure.

WARNING!

In correspondence to the heating pressure

relief valve foresee the installation of a

discharge pipe with a funnel and a siphon

which lead to an adequate drainage. The

drainage has to be controllable by sight.

If this precaution is not made, an eventual

intervention of the pressure relief valve could

cause injury to persons, animals or damage

to property. The manufacturer shall not be

held liable for any injury and/or damage.

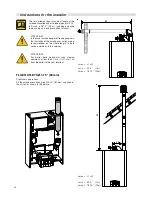

3.13 - CONNECTING THE EXPANSION

VESSEL IN A SINGLE BOILER

SYSTEM

CAUTION

Damage to the installation due to faulty

pressure relief valve.

An expansion tank must be part of the central heating system.

The expansion tank must be appropriate to the water content

of the installation. The pre-charge pressure depends on the

installation height above the mounted expansion tank.

1

R

M

G

NOTICE

The expansion tank is NOT a part of the delivery

and should be sourced locally. Please refer to

the expansion tank manufacturer for further in-

formation.

Fill expansion tank to a minimum of 14.5 psi.

NOTICE

For the boiler to function correctly, it is necessary

to connect the expansion tank to the expansion

tank connection on the boiler. If the expansion

tank is not connected to the supplied connection

damage to the boiler may occur.

This reliev valve comply with the standard for

Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems ANSI

Z21.22b-01(R08)/CSA 4.4b-01(R08)

and/or the standard Temperature, Pressure,

Temperature and Pressure Relief Valves and

Vacuum Relief Valves CAN1-4.4-M80