35

Instructions for the installer

3.25 -

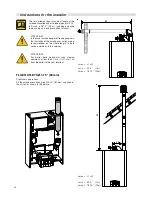

FILLING THE SYSTEM

WARNING!

Do not mix the CH system’s water with anti-

freeze or anti-corrosion solutions using wrong

concentrations! It could cause damage to the

washers and could provoke noise during

normal boiler operation.

LATTNER refuses all liability for injury to

persons, animals or damage to property

deriving from not having respected the above

mentioned recommendations.

Before filling the heating system, the complete system, inclu-

ding all zones, must be thoroughly cleaned and flushed to

remove sediment.

Flush until clean water runs free of sediment. LATTNER sug-

gests using an approved system cleaner to flush the system,

but not the boiler. Always use LATTNER approved antifree-

zes. See the list at page 7.

Never use reverse osmosis, D.I., or distilled water for filling

the heating system.

WARNING!

Do not use petroleum-based cleaning or sea-

ling compounds in the boiler system. Damage

of seals and gaskets in boiler and system could

occur, resulting in substantial property dama-

ge.

The central heating installation needs to be fil-

led with potable water.

Use only potable water or approved glycol for

filling the heating system.

When the water hardness of the filling water

exceeds > 8 gpg the water has to be treated

until below the maximum value of 8 gpg

The pH value of the installation water must be

between 6.5 and 8.5. Check the pH value using proper equi-

pment or by having the water analyzed by a water treatment

company.

If pH differs from above, contact LATTNER engineering for

further assistance.

Failure to adhere to the water quality requirements will result

in a void of warranty.

Once all the connections are made, it is possible to fill the

circuit.

This operation has to be performed very carefully, by obser-

ving the following steps (boiler in Off position):

- open the radiator bleeds and make ascertain the good

operation of the automatic air vent fitted in the boiler.

- open progressively the filling valve and make sure the

automatic air vent, in the system, work properly.

- close the bleeders of the radiators when water starts to

come out.

- control via manometer (Optional) that the water pressure

has reached a minimum value of 11,6/14,5 psi (0,8/1) bar

- close the filling valve and bleed again all the radiators.

- inspect for the soundness all the hydraulic connections.

- after the commissioning of the boiler and the reaching of

the normal operation temperature, switch off the operation

of the boiler and the pump and repeate the bleed opera-

tion.

- let the installation cool down and, if necessary, add water

in order to reach the minimum presure of 11,6/14,5 psi

(0,8/1) bar

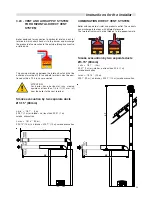

3.24 -

STARTING UP: Filling and de-aerating

the boiler and installation

CAUTION

Observe the following rules of safety:

- All work on the unit must take place in a

dry environment.

- LATTNER units may never be in operation

without their housing, except in connection

with maintenance or adjustments.

- Never allow electrical or electronic

components to come into contact with

water.

NOTICE

Carry out the following tasks in connection

with maintenance, etc. to an already installed

unit:

-

Shut down all programs

-

Close the gas shut off valve

-

Shut off the power at the main power switch

-

Close the service valves (supply and return)

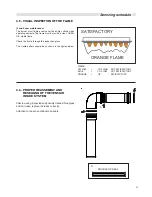

NOTICE

Take note of the following when maintenance

or adjustments are needed:

- The unit must be able to function during these

activities; for this reason, the unit’s supply

voltage, gas pressure and water pressure

must be maintained. Ensure that this is not a

source of potential danger during these

activities.

WARNING

Following maintenance or other activities;

always check the installation of all

parts through which gas flows (with bubble

test using leak-search spray).