16

Instruction for the installer

Prevalenza Disponibile all'Impianto

0

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

1,8

2

2,2

2,4

2,6

2,8

3

3,2

3,4

3,6

3,8

4

4,2

4,4

4,6

4,8

5

5,2

5,4

5,6

5,8

6

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

portata (l/h)

p

reval

en

z

a

(

m

H2O

)

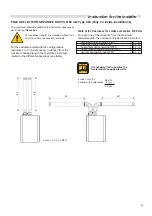

V1

V2

V3

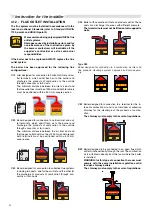

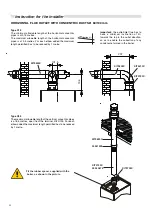

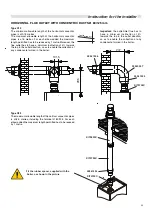

3.7 - CENTRAL HEATING CONNECTIONS

WARNING!

Before installing the boiler we recommend

that the system is flushed out with a suitable

product in order to eliminate any metallic

tooling or welding residues, oil and grime

which could reach the boiler and affect the

proper running of the boiler.

Do not use any solvents for flushing out the

system as they could damage the system

and/or its components.

Non-observance of these instructions could

cause injury to persons, animals or damage

to property. The manufacturer shall not be

held liable for any such injury and/or damage.

The CH flow and return circuits have to be connected to the

boiler via the respective connections ¾” M and R as indicated

on page 13.

When determining the size of the CH circuit pipes it is essential

to bear in mind the pressure losses induced by the radiators,

any eventual thermostatic radiator valves, lockshield valves

and by the system’s layout.

The routing of the piping has to be laid down taking all the

necessary precautions in order to avoid air locks and to

facilitate the continuous purging of the system.

Ensure yourself that the system’s piping is

not used as earth clamps for the electrical

or telephonic system. They are absolutely

unsuitable for this use. In a short time this

could cause serious damage to the piping,

boiler and radiators.

The boiler is fitted with an automatic BY-PASS (differential

valve with a flow rate of about 150 l/h) which always ensures

a minimum water flow rate to the heat exchanger even if, for

example, all the thermostatic valves fitted on the heating

system are closed.

Pressure relief valve drain pipe

In correspondence to the heating pressure relief valve

provision should be made to install a discharge pipe with a

funnel and a siphon which lead to an adequate drainage.

The

drainage has to be controllable by sight.

WARNING!

If this precaution is not taken it could lead to

injury to persons, animals or damage to

property.

The manufacturer shall not be held liable for

any such injury and/or damage.

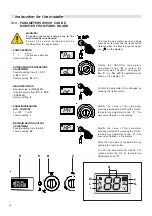

BOILER CIRCULATION PUMP

Graph – Water flow rate/ available head for installation– ALKON 24 kW

Manometric head available for C.H. system

Available head

(mc.a.)

Flow rate

(Q) l/h

Summary of Contents for ALKON R 18

Page 1: ...ALKON 09 R 18 C 18 R 24 C 24 00333176 2nd edition 10 2011 INSTALLATION AND SERVICING MANUAL...

Page 46: ......

Page 47: ......