43

Inspections and servicing schedule

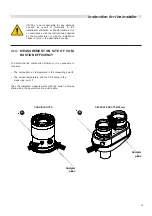

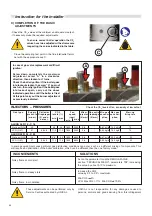

Example of crossed tightening sequence

1

3

4

2

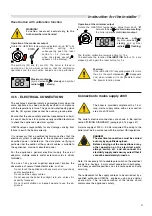

WARNING!

If, during the routine servicing, the burner

appears slightly curved, inflect the burner by

pushing from the outside of the curve and refit

it.

WARNING!

It is fundamental to correctly position the burner

in its dedicated seat.

Burner seat

Burner

Sealing gasket

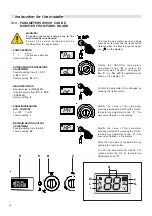

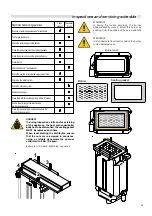

Recommended servicing operations

Examine all water seal components for soundness

Clean the combustion circuit heat exchanger/body

Clean the fan

Check the gas flow rate and eventual gas adjustment

Check the flue outlet system

Check the hydraulic system

Combustion analysis

Clean the DHW heat exchanger (only on the “C” model)

Control the efficiency of the electrical and

electronic components

Check

annually

Check every

2 years

Check efficiency of fan’s operation

Test for gas soundness

Clean the burner and check the ignition efficiency

Clean the condensate drain siphon and check that

it is discharging correctly

Check the water and gas safety devices

DANGER!

If, during inspection visits and/or servicing

of the appliance, the heat exchanger/boiler

body has to be dismantled, the sealing gasket

MUST be replaced each time.

When reassembling the distributor, ensure

that the nuts are re-screwed in sequence,

using a suitable dynamometric spanner

calibrated to 8 Nm (0,8 kgm).

Summary of Contents for ALKON R 18

Page 1: ...ALKON 09 R 18 C 18 R 24 C 24 00333176 2nd edition 10 2011 INSTALLATION AND SERVICING MANUAL...

Page 46: ......

Page 47: ......