15

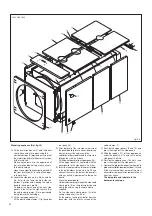

2.7 - BURNER

2.7.2 - CHOICE OF THE BURNER

The correct choise and the adjustment of the

burner are foundamental for the best operation of

the boilerand then they shall be accurate and

not underevaluated.

The burner will be selected by verifying that

its working diagram (fuel flow rate - pressure in

the furnace) is compatible with the same

features declared for the boiler.

Remember that the smoke side resistance, i.e.

the counterpressure in the furnace, are referred

to "0" draught at the chimney base.

It is also convenient that the burner blast tube

have its length not shorter than that shown in

table 18 and that the flame have a shape

suitable to the characteristics of the ELLPREX

furnace.

In fact to better exploit all the heating surface of

the reversed flame furnace it is necessary to

use burners capable to guarantee a long and

narrow flame at all operating conditions or also

at minimum input in case of two stage or

modulating burners.

Too short flames can cause a localized

overheating of the front part of the furnace, and

the combustion products, not sufficiently cooled

down, entering the smoke pipes at a too

high temperature, can cause important da-

mages to the boiler.

The burner manufacturing companies are

able to supply the flame dimensions

developped by their burners.

More informations are given in the paragraph

"Commissioning".

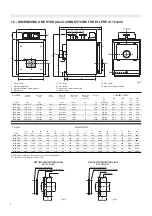

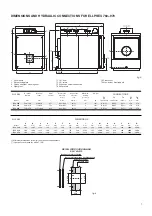

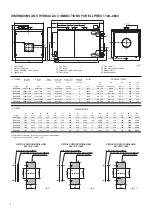

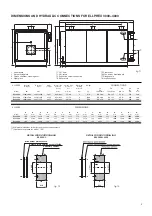

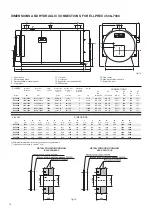

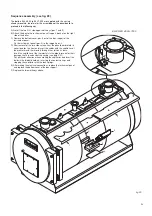

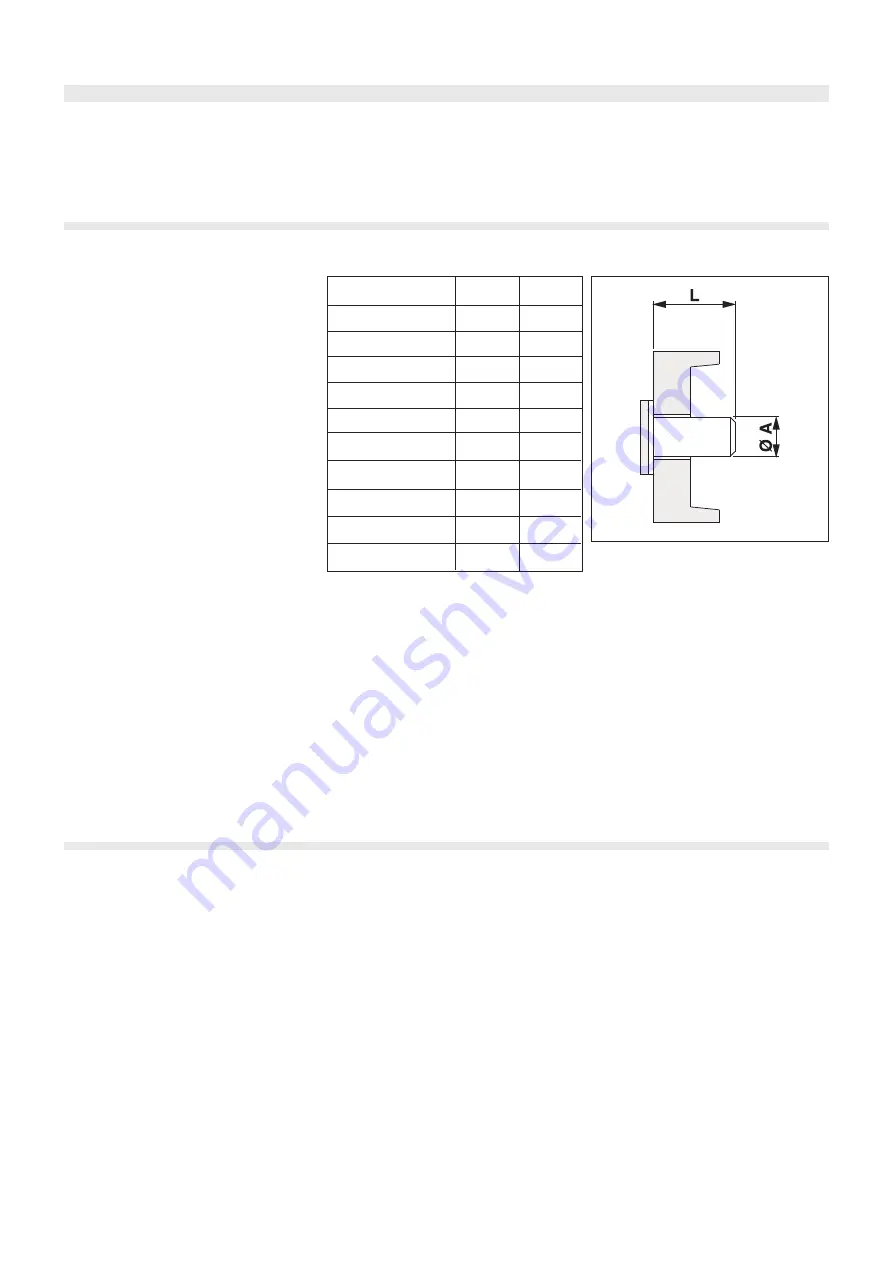

BOILER MODEL

øA

mm

L

mm

fig. 20

ELLPREX 2200 - 2650

380

350

ELLPREX 1570 - 1850

320

320

ELLPREX 1100 - 1320

320

300

ELLPREX 760 - 970

270

270

ELLPREX 290 - 630

220

250

ELLPREX 170 - 240

180

250

2.7.1 - CONFORMITY OF THE BURNER

All the burners equipping the ELLPREX boilers

must be CE certificated and must conform to

the following directives and standards:

- Gas Appliances Directive (90/396/CEE);

- EMC Directive (89/336/CEE).

- EN 267 - Automizing oil burners of

monobloc type - Testing -

- EN 676 - Automatic forced draught burners

for gaseous fuels.

ELLPREX 3000

380

400

BURNER BLAST TUBE MIN. LENGTH

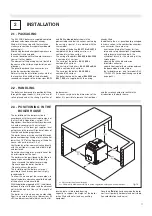

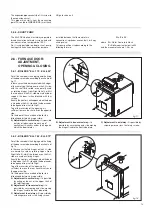

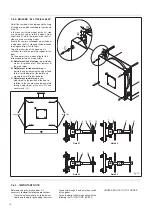

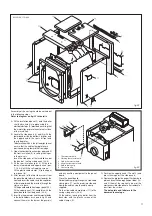

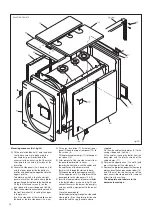

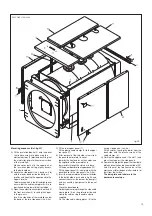

2.7.3 - BURNER INSTALLATION

Before fitting the burner it is necessary to verify

the position of the turbulators inside the smoke

pipes: each pipe must have its turbulator and

this one has to be positioned as indicated in

the table on page 33.

When mounting the burner to the boiler front

door, check for soundness around the burner

flange and its gasket.

Each boiler is supplied with a length of ceramic

fibre rope (cross section 25x25 mm).

This rope has to be put around the burner

tube to completely seal the tube and the

hole in the door insulation.

Be careful not to leave fissures between the

burner tube and the hole in the door.

In case a cone, having a diameter langer than

the burner tube, the cone is to be removed

before fitting the burner and refitted later on.

After the burner has been fitted, check that the

flexible hoses for the oil and the electrical cables

are long enough to allow the 90° opening of

the boiler door.

For gas burners the use of flexible pipes for

the gas is not allowed; so the final part of the

gas feeding line to the burner must have the

possibility to be removed, via a threaded or

flanged connection.

ELLPREX 3500 - 4000

400

400

ELLPREX 4500 - 6000

500

480

ELLPREX 6500 - 7000

500

630

Summary of Contents for ELLPREX Series

Page 1: ...26739 01 13 rev 4 ELLPREX INSTALLATION USE AND SERVICING INSTRUCTION to be kept by the user...

Page 37: ...37 Notes...

Page 38: ...38 Notes...

Page 39: ...39 Notes...