36

5.3 - EXTRAORDINARY

MAINTENANCE

Extraordinary maintenance of end season

or for long periods of inactivity.

It will be necessary to perform all the operations

described in the preceding chapter and

besides:

- Check the state of consumption of the

turbulators to replace them in time.

- To facilitate the extraction of the turbulators,

with the ELLPREX boilers a special extractor

is supplied.

- After the cleaning of the smoke circuit it is

convenient to pass in the smoke pipes and

in the furnace with a rag soaked of diluted

solution of caustic soda.

After having let to dry cross again all the

surfaces with a rag soaked of oil.

Perfectly close the the burner air intake to

avoid a continuous passage of damp air

through the boiler recalled by the chimney it

self.

It is advisable to put inside the furnace

some alive mortar that has an hygroscopic

action.

- Do not empty the C.H. system and the boiler.

- Protect the screws with graphitized fat, nuts

and pivots of the door.

- Show all the operations that must be

perform to the following put into operation

particularly the operation of the shunt pump

must be checked.

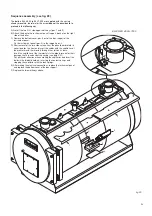

5.4 - CLEANING OF THE

BOILER

Follow the next sequence:

- Close the feeding of the oil.

- Cooldown the boiler to the ambient

temperature.

- Switch Off the electrical supply to the boiler

and the burner.

- Open the front door.

- Shake and remove the turbulators every 15-

20 days of activity of the boiler to avoid that

the residues of combustion can stop them so

much to make difficult their removal.

- Clean the turbulators and the smoke pipes

by brushing them with the brush supplied.

- Reposition the turbulators.

- Remove the cleaning door and all the soot

from the smoke chamber.

- Re-fit the cleaning doors.

- Verify the state of the refractory insulation

of the combustion chamber door.

- Verify the state of the door sealing rope.

- Close the door of the furnace.

5.5 - CHECK OF THE

BOILER OPERATION

For a safe operation of the boiler it is necessary

to check:

- The good operation of the working

thermostat.

5.6 - CHECK OF THE

BURNER OPERATION

- See the burner instruction manual.

- Follow all the local requirement in terms of

burner maintenance .

- The good operation of the high limit

thermostat.

- The adjustment and the good operation of

the minimum thermostat.

- The good operation of the shunt system.

- The good operation of the outer

compensator (if fitted).

- The good operation of all the other safety

and control devices imposed by local

requirements.

that cannot be attributed to the constructive

geometry and/or to the materials used and/to

the constructive technique and, therefore, they

are not covered by guarantee.

On the occasion of the ordinary maintenance it

is useful to perform a small discharge from the

boiler to verify if sludges escape.

In affirmative case, it will be necessary to

prolong the discharge up to get clear water.

At the end of the drainage it will be necessary

to reestablish the level of the water in the

system.

At the end of the smoke circuit cleaning, to the

next restart check around the burner plate and

the smoke chamber for smoke leaks. In the

case some smoke leaks were noticed, first of

all tighten the screws fitting the smoke and, not

5.7 - BOILER HOUSE

For the combustion of oil or gas the burner

needs air.

Accordingly wide openings are foreseen for the

entry of the air in the boiler house.

These openings never have to be obstructed.

Maintain the boiler house clean and dust free.

The boiler is not a closet: avoid to store any

kind of materials.

Maintain the entry of the boiler free and easy

to reach in any moment.

Ascertain that the boiler house is endowed with

efficient emergency lamp.

cleaning doors on the smoke chamber.

Besides it will be necessary to verify the good

operation of the protection and control

devices (thermostats, thermometers) of the

boiler and of the plant (manometers, flow

and pressure switches, expansion vessels)

and all the safety devices.

In this occasion it will be necessary to notice

the quantity of reinstatement water used and

decide, also in base to its hardness, an

intervention of preventive descaling.

It must be considered that the calcium and

magnesium salts dissolved in the raw water,

with repeated reinstatements, can cause

deposits in the boiler that hinder the inner

circulation and subsequent overheating of

the wall plates with possible serious damages

getting result, it will be necessary to replace

the sealing gasket.

Similarly it will be necessary to act on the front

door, increasing at first the tightening of the

nuts (after having loosened the inner

counternuts) and then, if necessary, by

replacing the whole gasket.

If it was necessary to center the sealing

gaskets on the sealing ring of the door it is

possible to adjust the door position by acting

as suggested on the paragraph 2.6.

At the end check and, if necessary, restore

the sealing of the connection of the chimney

and of the burner with the door.

The performed operations must be recorded on

the log book of C.H. system.

Summary of Contents for ELLPREX Series

Page 1: ...26739 01 13 rev 4 ELLPREX INSTALLATION USE AND SERVICING INSTRUCTION to be kept by the user...

Page 37: ...37 Notes...

Page 38: ...38 Notes...

Page 39: ...39 Notes...