10

Installation info

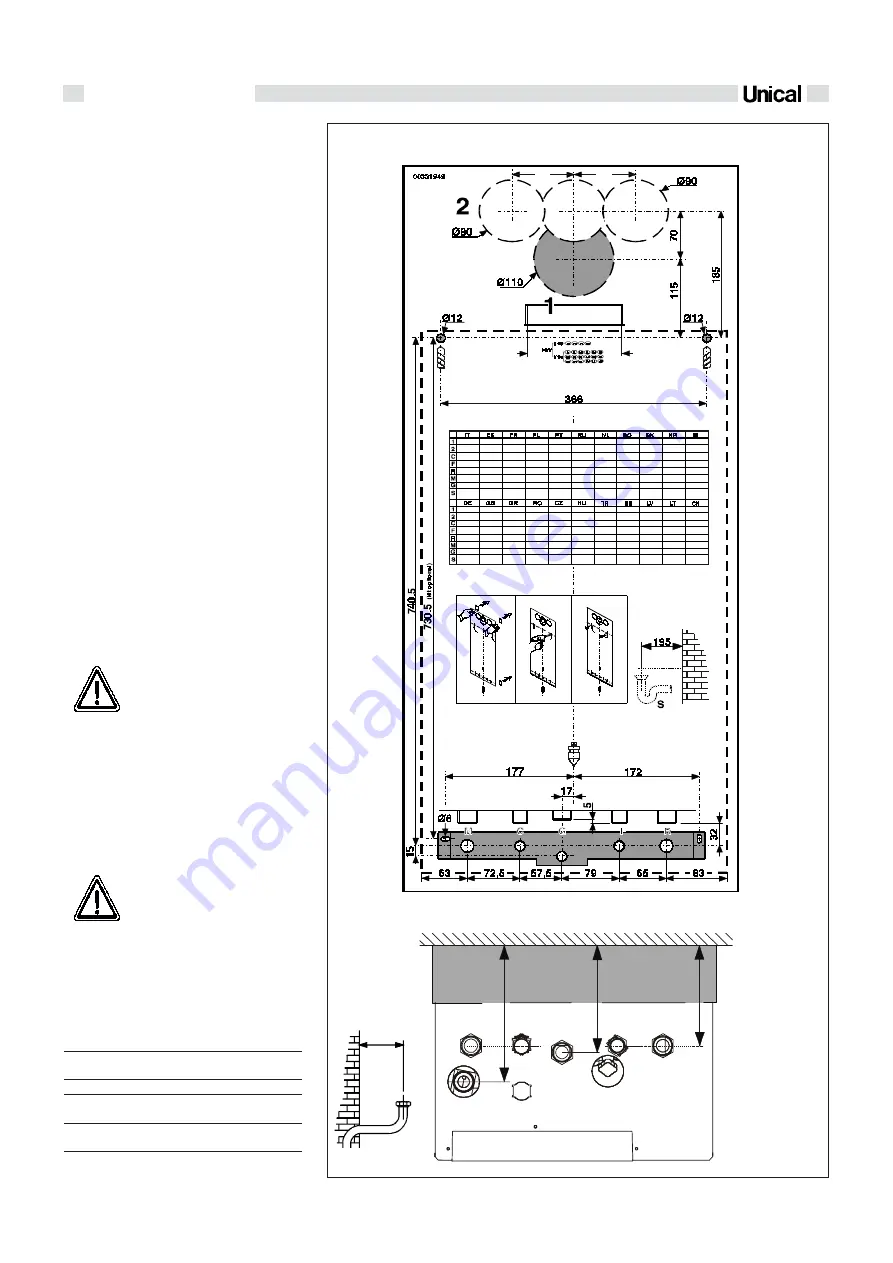

fig. 7

2.2.2 - POSITIONING THE BOILER

Every boiler is supplied with special “MOUN-

TING JIG” with which the pipes for connec-

tion to the system, D.H.W. and gas can be

positioned when the hydraulic system is being

laid out and before the boiler is installed.

This MOUNTING JIG, comprising a sheet of

strong paper which must be fixed to the wall

chosen for the installation of the boiler, gives

all the indications needed to make the holes

in the wall using two screws with expanding

dowels.

Use the lower part of the MOUNTING JIG to

mark the exact point of the connection of the

gas supply, cold water supply pipe, D.H.W.

outlet, C.H. flow and return.

When choosing the position of the boiler:

-

refer to the indications given in the section

“Flue gas evacuation system “.

-

leave a clearance of 50 mm on each side

of the boiler to facilitate maintenance ope-

rations.

-

check that the wall is suitable.

-

avoid fixing the boiler to thin partitions.

-

avoid installing the boiler above applian-

ces which might affect operation when in

use (cookers which produce greasy ste-

am, washing machines, etc.)

-

avoid installing natural draught boilers in

corrosive or very dusty atmospheres such

as hairdressers’, laundrettes, etc. as the

life of the boiler components could be si-

gnificantly shortened.

L

M

= C.H. system

flow

C

= D.H.W.

outlet

G

= Gas

F

= Cold water

inlet

R

= C.H. system

return

S

= Safety valve

discharge

Ø

L mm

= 3/4''

144

= 1/2''

144

= 3/4''

153,5

= 1/2''

144

= 3/4''

144

=

195,5

For IVEN 04 TFS

Since the temperature of the wall

on which the boiler is installed

and the temperature on the sur-

face of the coaxial duct do not

IVEN 04 TN

Maintain distance of at least 200

mm on the sides with wall which

have inflammable materials.

CONNECTION POSITION SEEN FROM ABOVE

MOUNTING JIGS FOR BOILER CONNECTIONS

increase, in normal operating conditions, more

than 60 K, it is not necessary to keep a mini-

mum distance from inflammable walls.

For boilers with dual suction and exhaust ducts,

place insulating material between the wall and

the pipe in the case of inflammable walls and

wall crossings.

195.

5

15

3.

5

144

M

C G

F

R

Filling of

C.H. system

Safety

valve discharge

85

85

Summary of Contents for EVE 05 CTFS 24 F

Page 35: ...35 ...