24

Installation instructions

5.6 - STARTING

IGNITION

Make sure that the checks listed in paragraph

5.5 have been performed.

Place, in the center of the grate, thin paper

(newspapers etc.) and a little thin and dry

wood, cross disposed; avoid large pieces in the shape of

squares

Open the rear by-pass

Light the paper and close the upper door. Wait for the fire to

start and produce the embers (5 to 10 minutes).

After that, looking through the secondary air inlet on the

upper door, the flame will be noticed .

Important: The by-pass should be used only at the start

and during subsequent loading,

During the operation, the

by-pass should always be tightly closed

1st LOADING

When the bed of embers is formed on the grate, it is

possible to proceed to the loading of the wood

Open slowly the upper door.

Spread the embers uniformly on the grate, using the poker.

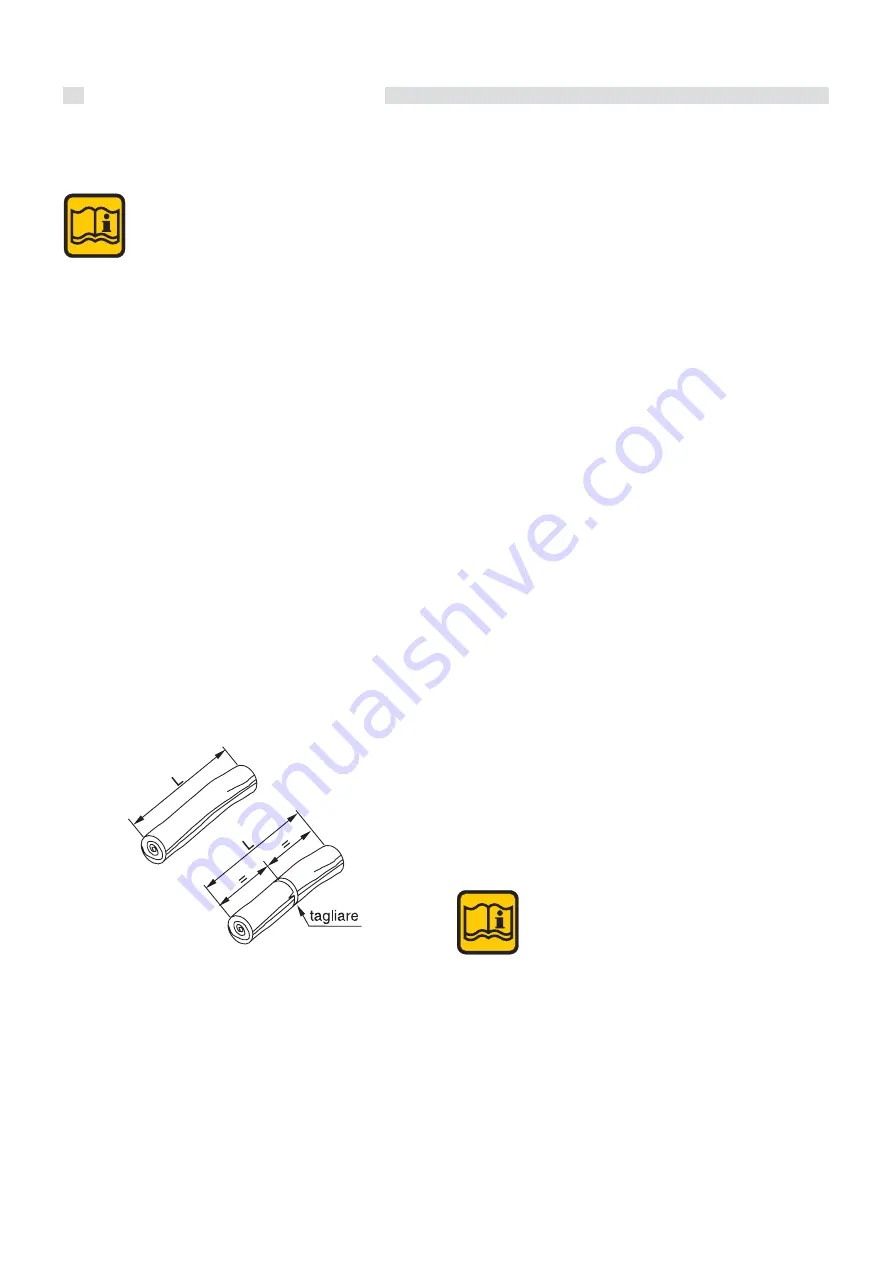

The wood must be of the following length:

a) 33 cm (+ 1 cm - 4 cm) for the model FOKOLUS 20

b) 50 cm (+ 1 cm - 4 cm) for models FOKOLUS 30

c) 70 cm (+ 1 cm - 4 cm) for the model FOKOLUS 40

These dimensions must be strictly observed.

Since for a good combustion it is essential that there is an

uniform falling down of the firewood, it is necessary to

make sure that the length of the introduced wood logs, their

form and the way of loading don’t prevent the regular

descent of the fuel.

The wood logs must be placed longitudinally and

horizontally. No log has to be placed slanting or athwart.

We recommend not to

use small wood pieces for fuel

charges, because they have an excessive inflammation

and can cause an unacceptable increase of the output and

of the smoke temperature in the chimney.

Caution: After wood loading close the upper door and

remember to close the by-pass.

SUBSEQUENT LOADINGS

Before making a new loading of wood, consume, as much

as possible, the previous one.

The new loading will be done when the bed of embers, on

the grate, will be reduced to a thickness of about 5 cm.

Open slowly the upper loading door.

Use only wood logs having a length as stated in the

previous paragraph.

Place the new loading of wood as above described.

USEFUL SUGGESTIONS AND LOADING ERRORS

- Too long logs do not fall down regularly and can cause

“bridges”.

- Too short logs cause not regular air passages, with

consequent reduction of output and efficiency.

- In case the quality of the wood causes “bridges” it could

be necessary to cut the wood logs in two parts, as stated in

the paragraph FIRST LOADING.

- Open the upper door always slowly, in order to avoid

blowbacks and smoke formations.

5.7 - COMBUSTION AIR ADJUSTMENT

ADJUSTMENT OF PRIMARY AND SECONDARY AIR

The boiler FOKOLUS is equipped with primary air (pos 5,

fig. 1) and secondary air adjustment (pos 4,Fig. 1). The

primary air adjustment is done automatically through the

thermostatic valve; the secondary air, however, done

through the port located on the upper loading door, must be

done by the user, tightening or loosening the adjustment

screw.

At the first start it is necessary to adjust the

primary and the secondary air and bearing in

mind that the primary air determines the boiler

output, and therefore the amount of wood that

is burned, and the secondary air completes the

combustion.

The optimal setting of the FOKOLUS operation

is obtained when boiler and chimney are in

“warm conditions”.

Once the thermostatic valve of the primary air adjustment

has been mounted according to the instructions of the

manufacturer, it is forbidden to open, manually, the primary

air adjustment door to activate the combustion after wood

loading, because it could be the cause of excessive output,

with an abnormal increase of the smoke temperature to the

chimney.

fig. 19