7

Instructions for the User

6.7 -

Maintenance on the boiler body

Danger!

Before doing any work on the boiler,

ensure that it and its components have

cooled down

.

Warnings

Never discharge water from the boiler and C.H. system, even

partially, unless really necessary.

Do not clean the boiler and / or its parts with flammable

substances (eg petrol, alcohol, etc.).

Do not leave containers of flammable substances in the

room where the boiler is installed.

USEFUL SUGGESTIONS

For cleaning, use brushes and vacuum

cleaners, if wiping clothes are used, make

sure that they are all retrieved.

Keep nuts and bolts protected with grease.

CLEANING AND ORDINARY MAINTENANCE OF A WOOD

FIRED BOILER

Every day

- Remove the ashes from the bottom tray

- Remove with the poker supplied with the boiler, the bed of

embers in order to let fall down, through the slots of the

grate, the ashes accumulated in the wood storage.

Every week

- Carefully remove, from every point, any residue of

combustion accumulated in the wood storage.

- Clean, with the brush supplied, the upper smoke dry

passages of the furnace

- Remove the ashes accumulated in the smoke chamber

through the rear cleaning door

- Make sure that the slots of the grate are not clogged, and

if they are, make free the slots with the poker’s help

Every month

Check the operation of the by-pass and its tightness as

described in chapter 5.5.

EXTRAORDINARY MAINTENANCE OF A WOOD FIRED

BOILER

After each heating season, make a general cleaning of

the boiler by taking care to remove all the ashes from

wood storage. During the summer, close the doors of

the boiler.

The grates are subject to consumption; it is, then,

advisable their annual inspection, in order to avoid

an anomalous operation of the boiler.

ORDINARY CLEANING AND MAINTENANCE OF

A POSSIBLE OIL OR GAS FIRED AUXILIARY

BOILER.

Before the beginning of each heating season

The boiler body has to be checked and cleaned by autho-

rized personnel.

Inpesction of the burner

Possible inspection on oil or gas fired burner equipping

the auxiliary boiler has to be performed by authorized per-

sonnel of the burner manufacturer.

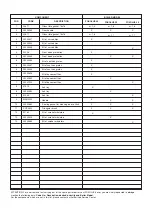

Summary of Contents for FOKOLUS

Page 1: ...USER S INSTRUCTIONS 00333935 Ed 12 2010 FOKOLUS ...

Page 9: ...Easy replacement spare parts ...

Page 11: ...Notes ...