5

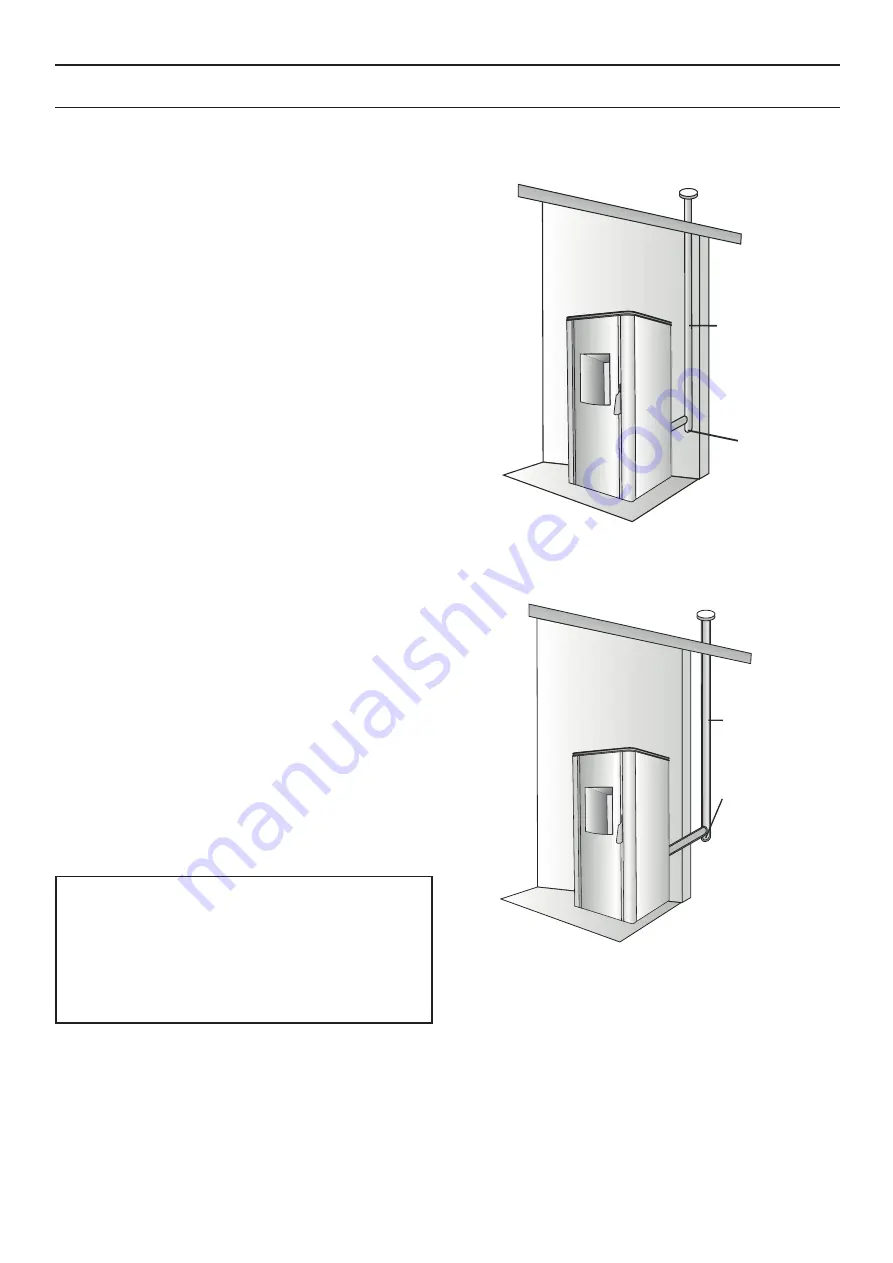

Flue gas exhaust

Combustion products must be exhausted

through the roof.

There must be one exhaust system for the stove

(there cannot be exhausts in a flue shared with

other devices).

Flue gas must be exhausted through a pipe

diameter 80mm placed at the back.

There must be a tee with a condensate collection

cap at the start of the upright section.

The stove flue gas exhaust must be connected to

the outside using steel or black pipes (resistant

to 450°C and beyond) without obstructions.

The pipe must be airtight. The pipes must be

sealed and insulated using materials resistant to

at least 300°C (high temperature silicon or putty).

The horizontal sections

can be up to 2m long

.

There can be up to three 90° elbows.

The vertical pipe can be inside or outside.

The smoke duct must be appropriately insulated.

If the smoke duct is inserted in a flue, this must

be authorised for solid fuels and if the diameter

is larger than 150 mm, it must be re-established

by piping and sealing the exhaust respect to the

part in masonry.

All sections of the flue gas pipe must be able to

be inspected. If fixed, it must have inspection

openings for cleaning.

According to the standard UNI 10683/05 and

subsequent amendments, the stove must

not be in the same room with extractor fans,

gas appliances or devices which can create a

vacuum in the room.

Installation

The adjacent room cannot be used as a

garage, storeroom for combustible material

or any activity involving fire hazard.

Fig.3: installation of indoor flue to be made according to

standards

Fig.4: installation of outdoor flue

Insulated

piping

Condensate

collection

cap

Insulated

piping

Condensate

collection

cap