20

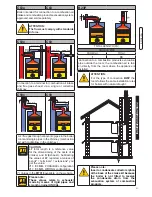

3.6 - FLUE GAS EXHAUST PIPE CONNECTION

FOR BOILERS wITH FORCED DRAUGHT

To connect the flue gas exhaust pipe, local and na

-

tional standards must be observed

In the event the boiler is replaced, ALwAYS re-

place the flue gas pipe as well.

The boiler is type approved for the exhaust configu

-

rations listed below:

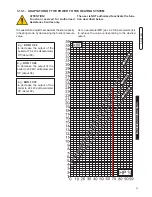

C13x

C13

% Slope towards inlet = 3%

TOTAL LENGTH (LA L Exhaust)

COAXIAL Ø60/100

DOUBLE Ø80

FROM [m]

TO [m]

FROM [m]

TO [m]

1

5,5

1 + 1

40

(20A+20S)

COAXIAL Ø80/125

DOUBLE Ø60

FROM [m]

TO [m]

FROM [m]

TO [m]

1

8

1 + 1

20

(10A+10S)

Distance between air

inlet pipe and flue gas

exhaust pipe: min 250

mm - max 500

Horizontal

exhaust and intake terminals directed

outside via coaxial or double pipes.

.

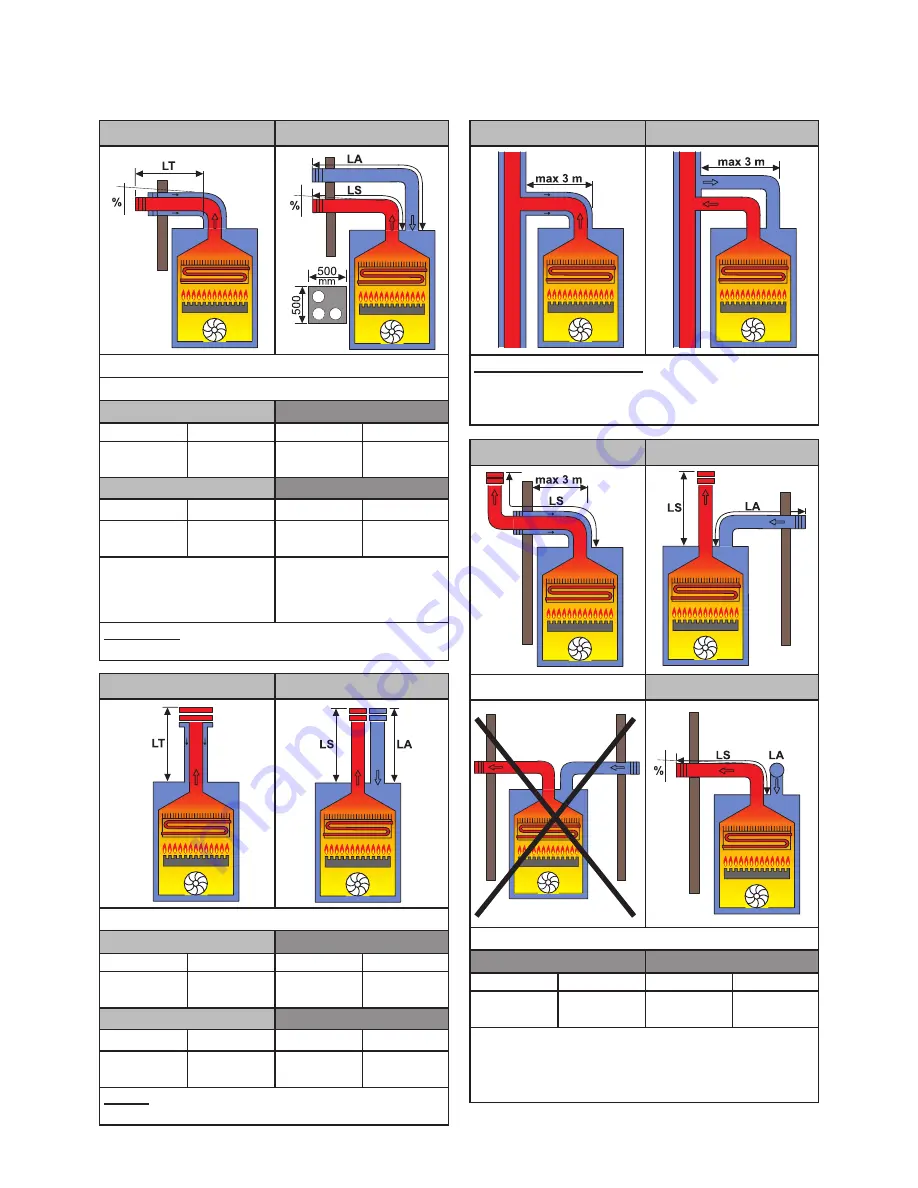

C33x

C33

TOTAL LENGTH (LA L Exhaust)

COAXIAL Ø60/100

DOUBLE Ø80

FROM [m]

TO [m]

FROM [m]

TO [m]

1

7

0,5 + 0,5

40

(20A+20S)

COAXIAL Ø80/125

DOUBLE Ø60

FROM [m]

TO [m]

FROM [m]

TO [m]

1

9

1 + 1

20

(10A+10S)

ertical

exhaust and intake terminals directed out-

side via coaxial or double pipes.

C53x

C53

C53

NOT ALLOwED

C53

TOTAL LENGTH (LA L Exhaust)

DOUBLE Ø80

DOUBLE Ø60

FROM [m]

TO [m]

FROM [m]

TOA [m]

1 + 1

40

(max 30 S)

1 + 1

20

(max 15 S)

Separate combustion air intake and combustion

products evacuation pipes.

These pipes can discharge into areas with different

pressure.

C43x

C43

Collective chimney flue

system, consisting of two

pipes, one for combustion air intake and the other

one for combustion products evacuation, coaxial

or double.