29

Maintenance instructions

ENGLISH

ROUTINE YEARLY VERIFICATION OPERATIONS

COMPONENT:

VERIFY:

CONTROL/INTERVENTION METH-

OD:

VG

(Gas valve)

( 3 )

Does the valve modulate properly?

The verification is performed on the

“Calibration” requiring 100%, in 50%,

the minimum percentage of modula-

tion.

Make sure that the flame modulate.

SR (heating sensor)

( 11 )

SS (domestic hot water sensor)

( 1 )

Do the sensors maintain the

original characteristics?

12571 ohm at 20° C / 1762 ohm at

70° C.

Measurement to be taken with the

wires disconnected (see table Res/

Temp)

.

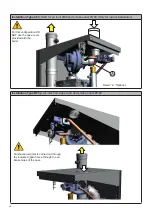

E ACC (ignition electrode)

( 28 )

E. RIV. (detection electrode)

( 27 )

Does the discharge of sparks before

putting the boiler in safe conditions last less

than 3 sec.?

Flame present but no detected.

Detach the electrode ionisation wire

and check the securing time.

Check for cable connection (faston

oxidation) or condition / detection elec-

trode positioning.

TL (anti-overheating

limit thermostat)

( 10 )

Does the TL put the boiler in safety conditions

when overheating?

Heat the TL until it intervenes at 102°C

and check that it intervenes at 102°.

DK (safety pressure switch against

water deficiency)

( 13 )

Does the pressure switch block the boiler

if the water pressure is below 0.4 bar?

Without request: close the shut-off valves

of the heating circuit, open the drain

valve to make the water pressure de

-

crease. Before pressurising again, check

the pressure of the expansion vessel.

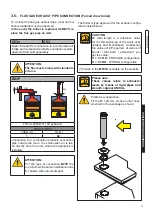

Condensation drain trap

(27)

Has the trap got deposits on the bottom?

Clean the trap with water.

Heat exchanger body

( 9 )

1) Measure the Thermal Capacity using a me-

ter and compare the value with that contained

in table 3.12. The data measured indicates if

the exchanger needs cleaning.

2) Check that the space between the rungs of

the exchanger are not clogged

It is recommended to use the products

purposely created by Unical (see sys-

tem protection ACCESSORIES sect. in

the domestic price list), being careful

to wash the area with most rungs first

(lowest part visible from above) and

then the upper part if necessary.

Burner

( 5 )

Check the state of cleanliness of the burner

mesh

Remove any deposits using com

-

pressed air, blowing from the mesh

side.

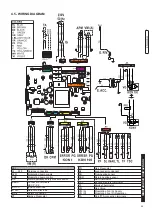

( Num ) =

see key Par. 2.2

Summary of Contents for KONf 100

Page 1: ...100 115 KONf E N G L I S H INSTALLATION AND SERVICING MANUAL ...

Page 10: ...10 2 3 DIMENSIONS Front view View from above Left Side view ...

Page 38: ...38 ...

Page 39: ...39 ...