6

GENERAL DESCRIPTION

1

1.1 - TECHNICAL /

FEATURES

-

MODULEX is a compact, gas fired,

Low NO

x

, condensing boiler, made

up by one sectional boiler body (so

called

heat module), set to operate

separately or in cascade.

This heat module consists of two or

more thermal elements (from 4 to 7),

which cannot be separated from

each other, being under the same

protecting casing. These thermal ele-

ments are connected to a single

smoke exhaust manifold and are

controlled by a single microproces-

sor which manages completely the

temperatures from the point of view,

both operational and safety.

-

If, for instance, one of the thermal

elements whose the boiler is com-

posed, goes out of order, the other

thermal elements continue to sup-

ply their output. It is nearly impossi-

ble the boiler go completely out of

order.

-

MODULEX has been examined ac-

cording the following European di-

rectives:

-

(GAD) Gas Appliances Directive

No. 90/396 CEE

-

(BED) Boiler Efficiency Directive

No. 92/42 CEE

by CERTIGAZ, under the No.

1312BP4012, for type B23 operation,

i.e. the boiler can be connected to a

traditional natural draught chimney,

and for operation in category I

2H

(G20

–20 mbar).

It also conforms to the following Eu-

ropean directives:

-

EMC (Electro Magnetic Compatibi-

lity) Directive No. 89/336 CEE

-

LVD (Low Voltage Directive)

No. 73/23 CEE

-

Machines Directive

No. 89/392 CEE

-

The boiler body, made by sections

of cast aluminium/magnesium/sili-

cium alloy, is conceived to recover

the sensible and the latent heat of

the combustion gases, thus al-

lowing to reach an efficiency of

109% on the N.C.V.

-

Each thermal element, composed of

a combustion chamber with burner,

modulating fan with control pressu-

re switch, gas valve, ignition devi-

ce, flame control, NTC sensor for lo-

cal temperature control and safety

thermostat, can deliver an output

between a maximum of 90 kW and a

minimum of 22 kW.

-

Each single boiler is equipped with

NTC sensors for global temperatu-

re control on the flow and return ma-

nifolds.

-

Total premix modulating bur ner

equipped with metallic sponge ra-

diation burner.

Premix in the pre-combustion cham-

ber. Automatic no return diaphragm

for separation from combustion

chamber.

-

Combustion air suction/feeding sy-

stem from the boiler house

-

Possible cascade installation of 2 or

more MODULEX

-

Heating Operation: setting of instan-

taneous output by a main micropro-

cessor, with a comparison parame-

ters pre-setting between the reque-

sted temperature (or calculated by

the outer compensator) and the glo-

bal flow temperature.

-

Logic of operation:

A) Output sharing on as many mo-

dules as possible at min. load (down

to 22 kW) for the max. efficiency.

B) Automatic operation hour split-

ting-up system for each module to

guarantee the best homogeneous

use.

C) DHW production by a priority sen-

sor which, thanks to the dedicated

electronic board, drives a special

loading pump or a 3-way diverting

valve for the preparation of a stora-

ge tank with the possibility of pre-

setting the D.H.W. circuit output, up

to maximum 360 kW.

D) Output check of each module for

any calibration and/or assistance by

secret access code.

-

Control panel with alphanumeric di-

splay, programming keys, reset and

hydrometer.

-

Displays: global flow/return tempera-

ture, DHW temperature, external tem-

perature.

-

Adjustments: flow temperature, fan

speed, max/min. output percentage.

-

Access to all testing/programming

parameters of each module: operation

test, operation time, boiler anti-frost

protection from 7°C, pump’s anti-

blocking system.

-

Integral easily removable panel set

(painted steel panels).

-

Condensate collecting tank equip-

ped with drain siphon and stain-

less steel smoke chamber.

-

Built-in air vent.

-

Weights and dimensions are limi-

ted (see table at par. 1.2).

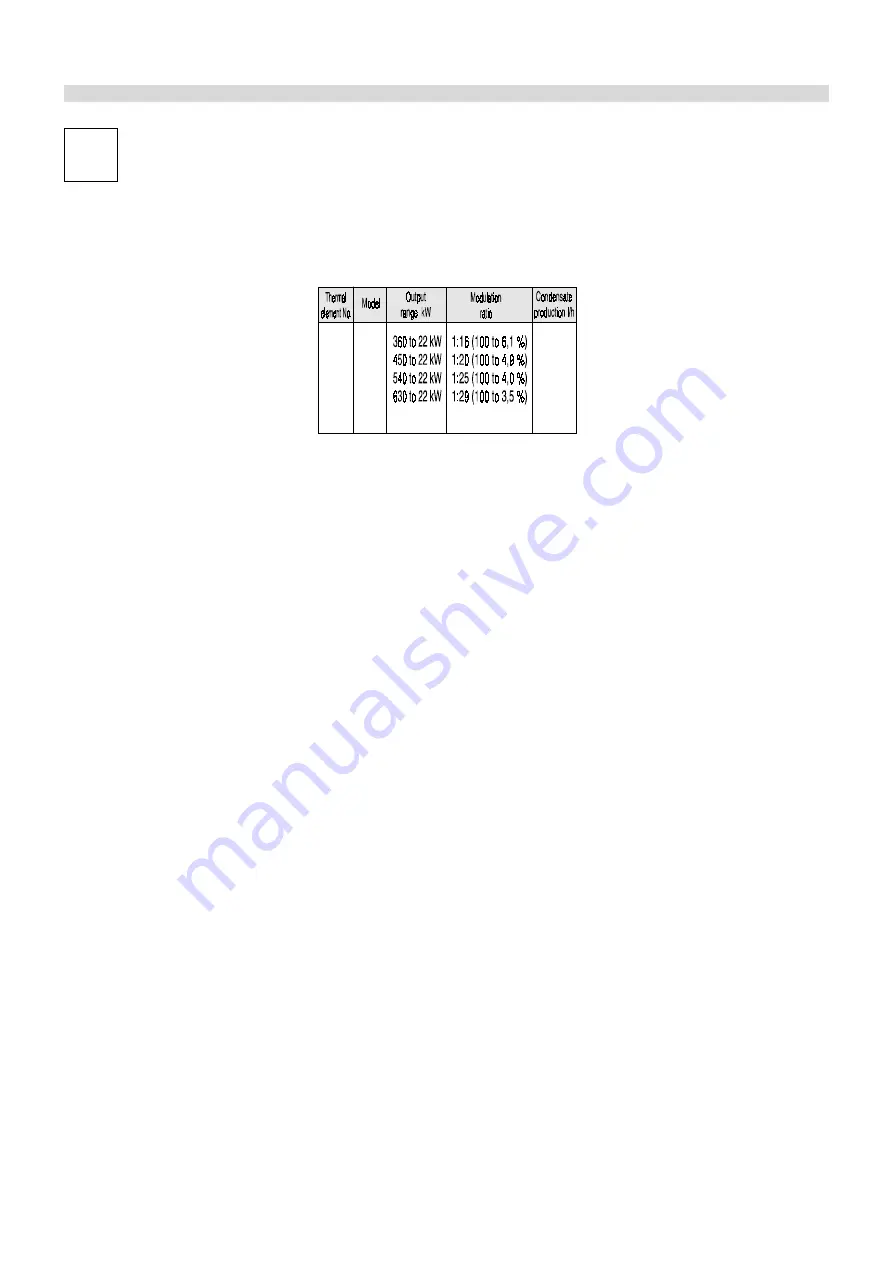

4

5

6

7

360

450

540

630

60

75 l/h

90 l/h

105 l/h

l/h