15

Tec

hnical f

eatures and dimensions

3

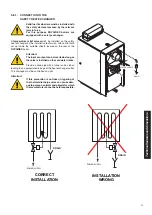

INSTRUCTIONS FOR

INSTALLATION

3.1 - GENERAL WARNINGS

ATTENTION!

This boiler is intended solely for the use for

which it was expressly designed. Any other

use is to be considered improper and there-

fore dangerous.

This boiler heats water at a temperature

lower than the atmospheric pressure boiling

temperature.

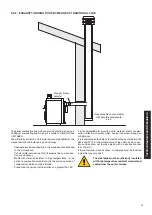

ATTENTION!

The appliances are designed to be installed

inside suitable rooms or technical spaces

only. The appliances cannot be installed or

operate outdoors. Outdoor installation can

cause malfunctioning and be dangerous.

Choose specifically designed appliances for

outdoor installation.

Before connecting the boiler, have professionally

qualified personnel:

a) Thoroughly wash all the piping of the system

to remove any residue or impurities which

could jeopardise proper operation of the

boiler;

b) Check that the chimney/flue has an appropri-

ate draught, without any bottlenecks, and that

no exhausts from other appliances are insert-

ed, unless the flue has been implemented to

accommodate several utilities according to

specific standards and prescriptions in force.

Only after this check can the fitting between

the boiler and chimney/flue be mounted;

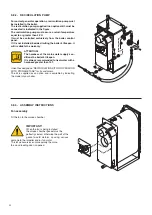

ATTENTION!

The appliance must be installed by a qualified

technician with the technical-professional

requirements according to law 37/08 which,

under his own responsibility, guarantees

compliance with the standards according to

good practice rules.

The boiler must be connected to a central heat-

ing system and/or domestic hot water production

network compatible with its efficiency and output.

3.2 - INSTALLATION STANDARDS

It must be installed by a professionally qualified technician,

who

shall take the responsibility of observing all local and/or

national laws published in the official journal, as well as

applicable technical standards.

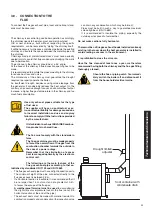

3.3 - INSTALLATION ON

OLD OR RETROFITTABLE SYSTEMS

Before installing this appliance on old systems, check that:

- The flue is able to withstand the temperature generated by

the combustion products, has been measured and designed

according to the regulations in force, is airtight and insulated,

and does not feature obstructions or constrictions.

- The flue has a device for releasing condensation.

- The electrical system has been set up by a qualified techni-

cian in compliance with the rules in force.

- The rate, head and direction of the flow of the circulation

pumps are appropriate.

- The expansion vessel(s) can fully absorb dilation of the fluid

in the system.

- The expansion vessels can fully absorb dilation of the fluid

in the system.

- The system has been cleaned and cleared of all sludge and

scale, has been vented, and all its seals have been checked.

- There is a water supply treatment/recirculation system.

Summary of Contents for NOVAIREX 35

Page 1: ...INSTALLATION AND MAINTENANCE INSTRUCTIONS NOVAIREX 35 45 55 ...

Page 55: ......