29

Tec

hnical f

eatures and dimensions

ENGLISH

AttENtIoN!

Remove cap 2,

Insert the co2

analysis probe

into the hole.

Air

drop

3.11.2 - POSITIONING THE PROBES

SPK 150

the following instructions are intended exclusively

for

authorised service personnel

.

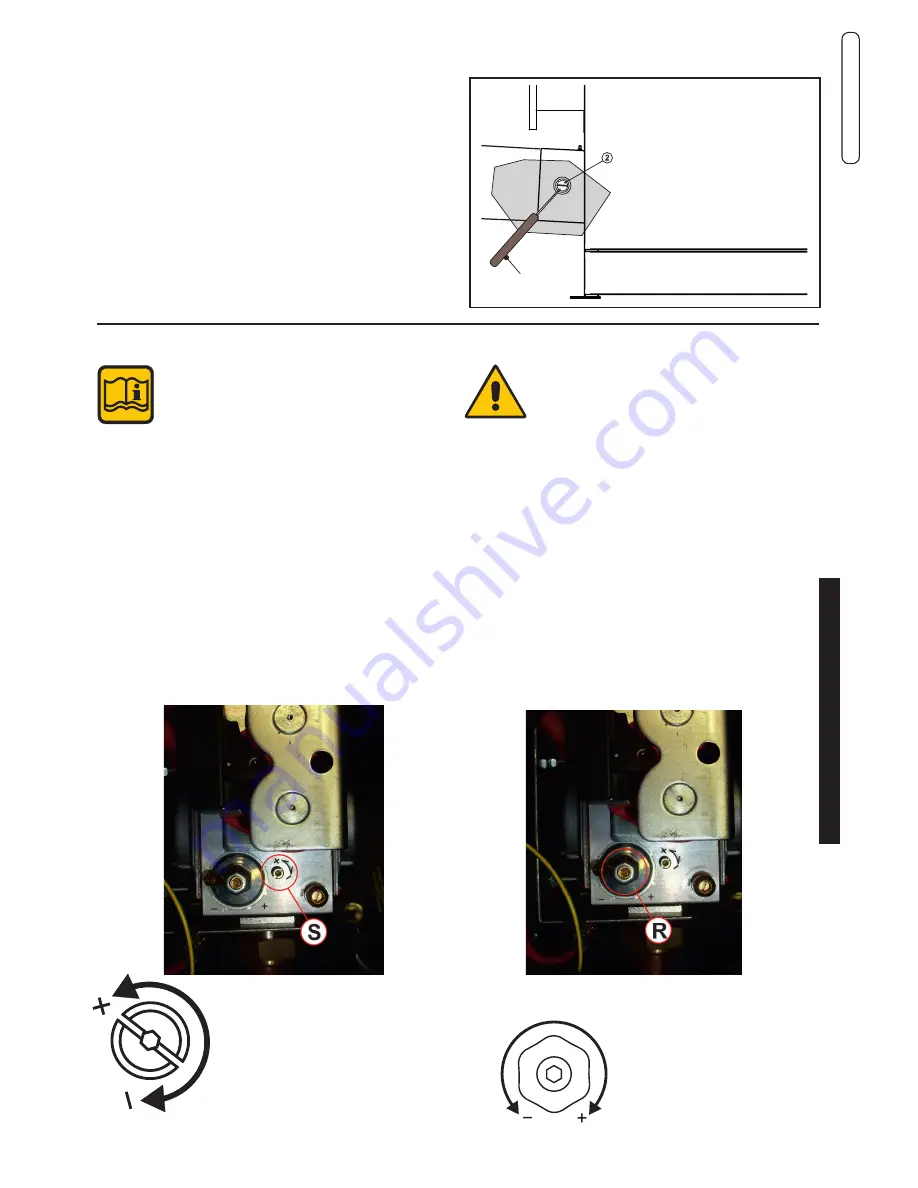

3.12 - ADJUSTING THE BURNER

(S)

ADJUSTMENT SCREW

MAXIMUM OUTPUT

(R)

ADJUSTMENT SCREW

MINIMUM OUTPUT

- Remove the cap and insert the co2 analysis probe in the

flue gas sample point of the intake/exhaust terminal, see

chap. 3.11.2.

All boilers leave the factory already calibrated and

tested, however, in the event gas valve recalibration

is required (moduLE 1, moduLE 2)

To determine the combustion efficiency

one must make the following measurements:

- measurement of the combustion air temperature

- measurement of the flue gas temperature and content of

co

2

taken in the relevant hole 2.

take the measurements with the generator in steady state

conditions (see par. 3.11.1).

2) Minimum output adjustment

- operate the boiler in “calibration” mode at mINImum outPut

(see 3.11.1)

- once the burner is on, check that the “mINImum” co2 output

value corresponds to what is indicated in the table “NOZZLES

- PRESSuRE”.

- If necessary, adjust the value by turning (with a 2.5 mm hex

key) screw

“R”

cLocKWISE to increase it, ANtIcLocK-

WISE to decrease it

(see table NOZZLES-CAPACITY-PRESSURE).

1) Maximum output adjustment

- operate the boiler in “calibration” mode at mAXImum out-

Put (see 3.11.1)

- once the burner is on check

that the “mAXImum” co2 output value corresponds to that

indicated in the table “NOZZLES - PRESSURE”.

- If necessary, adjust the value by turning the

‘’S’’

adjustment

screw CLOCKWISE to decrease it and ANTICLOCKWISE

to increase it

(see table NOZZLES-CAPACITY-PRESSURE).