30

SPK 230 - SPK 300 - SPK 400 - SPK 500 - SPK 600

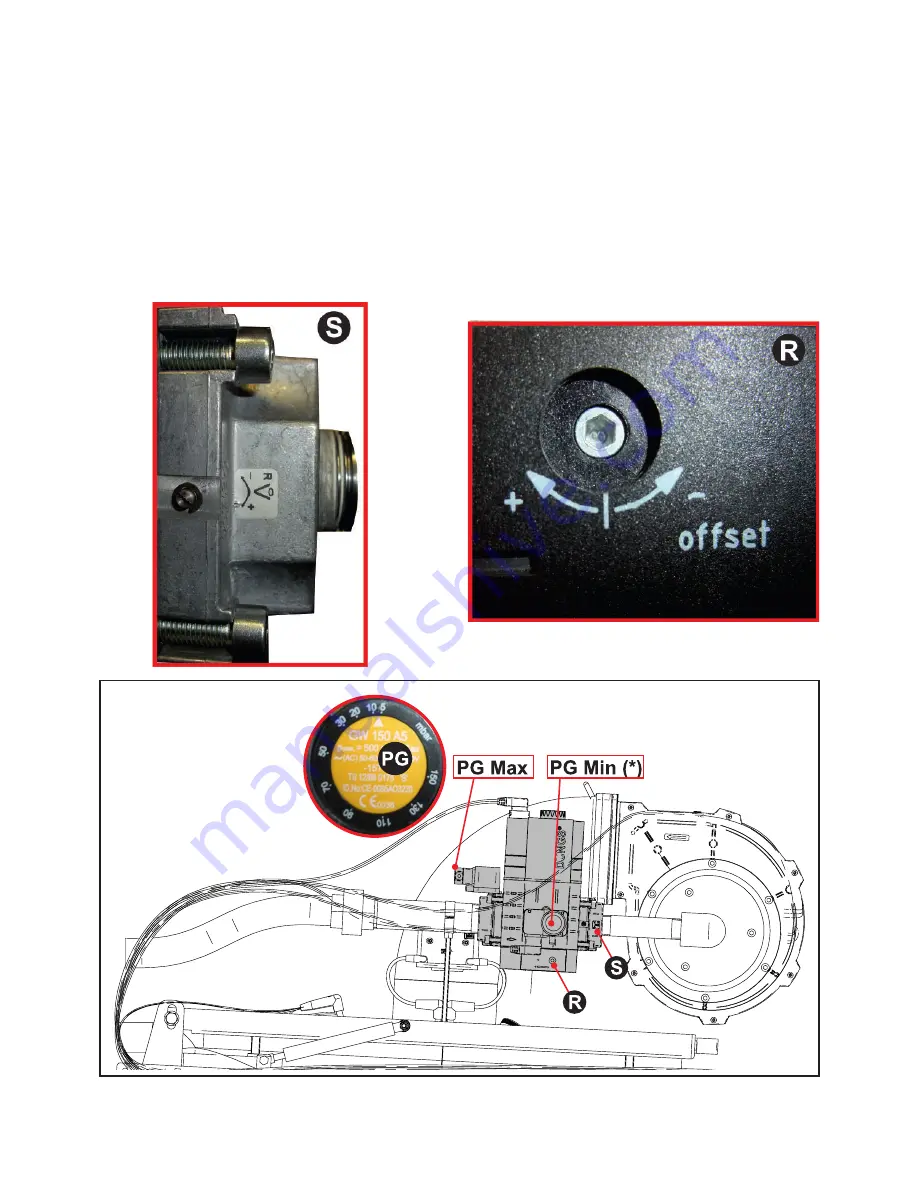

1) Maximum output adjustment

- operate the boiler in “calibration” mode at mAXImum out-

Put (see 3.11.1)

- once the burner is on check

that the “mAXImum” co2 output value corresponds to that

indicated in the table “NOZZLES - PRESSURE”.

- if it does not correspond, correct it by turning screw

“S”

cLocKWISE to increase it, ANtIcLocKWISE to decrease

it.

(see table NOZZLES-CAPACITY-PRESSURE)

.

2) Minimum output adjustment

- operate the boiler in “calibration” mode at mINImum outPut

(see 3.11.1)

- once the burner is on, check that the “mINImum” co2 output

value corresponds to what is indicated in the table “NOZZLES

- PRESSuRE”.

- If necessary, adjust the value by turning (with a 2.5 mm hex

key) screw

“R”

cLocKWISE to increase it, ANtIcLocK-

WISE to decrease it

(see table NOZZLES-CAPACITY-PRESSURE)

.

(S) MAXIMUM OUTPUT ADJUSTMENT SCREW

(R) MINIMUM OUTPUT ADJUSTMENT SCREW

GAS VALVE (Side view)

PG = GAS PRESSURE SWITCH

(*) ONLY ON SPK 400 / 500 / 600