34

fig. 36

8.3 - EXTRAORDINARY

MAINTENANCE

Extraordinary maintenance of end season

or for long periods of inactivity.

It will be necessary to perform all the operations

described in the preceding chapter and

besides:

-

Check the state of consumption of the

turbulators to replace them in time.

-

After the cleaning of the smoke circuit it

is convenient to pass in the smoke pipes

and in the furnace with a rag soaked of

diluted solution of caustic soda.

After having let to dry cross again all the

surfaces with a rag soaked of oil.

Perfectly close the the burner air intake

to avoid a continuous passage of damp air

through the boiler recalled by the chimney

it self.

It is advisable to put inside the furnace

some alive mortar that has an hygroscopic

action.

-

Do not empty the C.H. system and the

boiler.

-

Protect the screws with graphitized fat,

nuts and pivots of the door.

-

Show all the operations that must be

perform to the following put into operation

particularly the operation of the shunt

pump must be checked.

8.4 - CLEANING OF THE

BOILER

Follow the next sequence:

-

Close the feeding of the oil.

-

Cooldown the boiler to the ambient

temperature.

-

Switch Off the electrical supply to the

boiler and the burner.

-

Open the front door.

-

Remove the cleaning doors from the smoke

chamber.

-

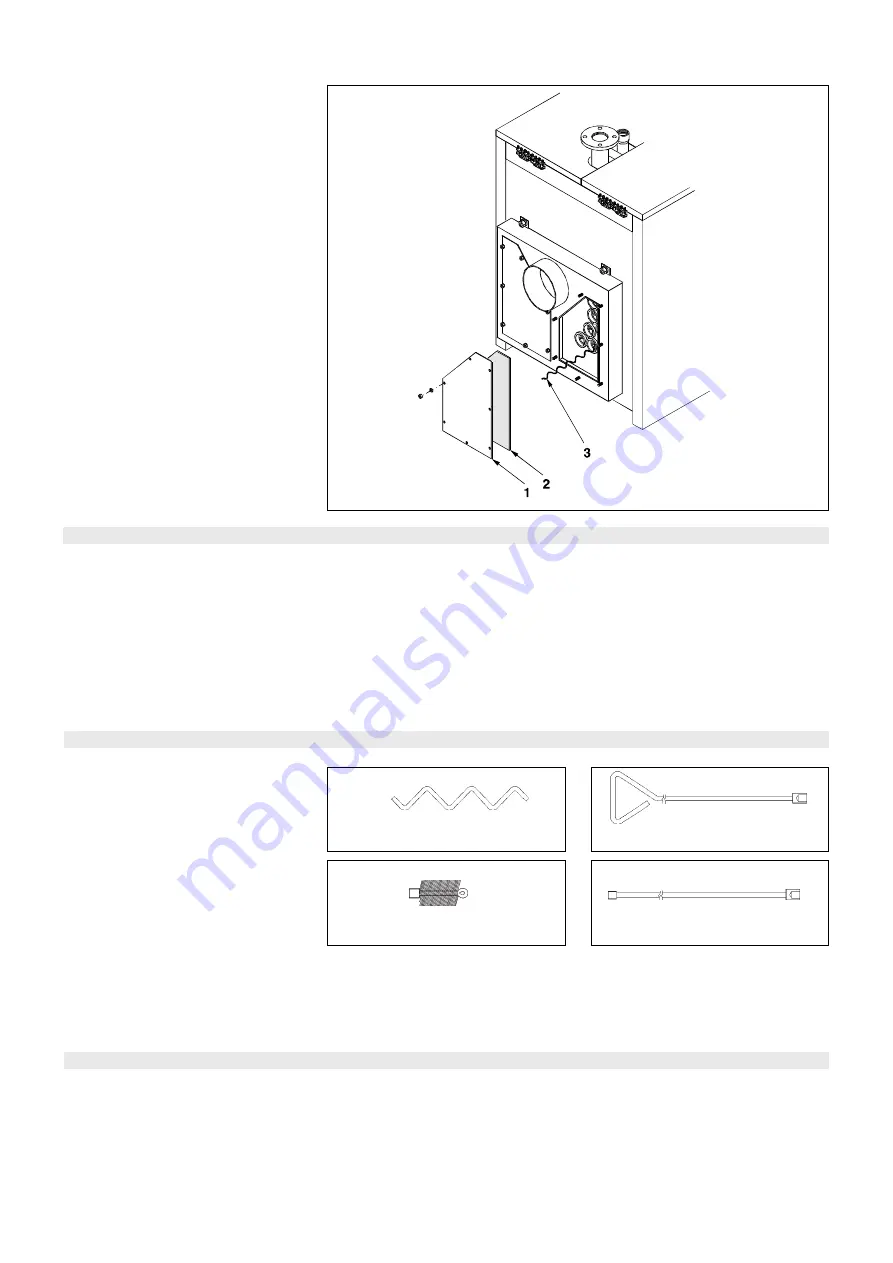

Shake and remove the turbulators (fig. 37)

every 15-20 days of activity of the boiler

to avoid that the residues of

combustion can stop them so much to make

difficult their removal.

-

Clean the turbulators and the smoke pipes

fig. 37

Turbulator

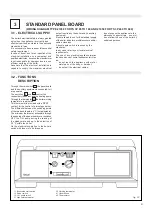

fig. 38

Triangular brush

fig. 39

fig. 40

Brush handle

Brush handle extension

(if applicable)

by brushing them with the brush (fig. 38)

fitted to the brush handle (fig. 39) and

relevant extension (fig. 40) supplied.

-

Reposition the turbulators.

-

Remove all the soot from the smoke

chamber.

-

Re-fit the cleaning doors.

-

Verfy the state of the refractory insulation

of the combustion chamber door.

-

Verify the state of the door sealing rope.

-

Close the door of the furnace.

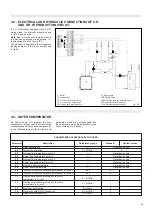

8.5 - CHECK OF THE

BOILER OPERATION

For a safe operation of the boiler it is necessary

to check:

-

The good operation of the working

thermostat.

-

The good operation of the high limit

thermostat.

-

The adjustment and the good operation

of the minimum thermostat.

-

The good operation of the shunt system.

-

The good operation of the outer

compensator (if fitted).

-

The good operation of all the other safety

and control devices imposed by local

requirements.