Technical features and dimensions

7

2.1 - TECHNICAL FEATURES

The XC-K boilers are made up of an external shell which houses

the completely wet blind cylindrical furnace, where the first

two combustion gas passes are completed, and by a special

tube and shell, used for the third pass.

The tube and shell, placed horizontally in the lower part of the

body, is composed of stainless steel 316L tubes and aluminium

fins.

The guided path of the combustion gas exploits the thermal

exchange surfaces to a maximum and evenly balances strains

on the materials.

The construction fully complies with prescriptions laid down in

EN 303 part 1.

The components of the pressurised part, such as sheets and

tubes, are made in certified carbon steel, according to the

EURONORM 25 and EURONORM 28 tables.

Welding devices and procedures are approved by TÜV (D) -

UDT (PL) - SA (S) and ISPESL (I).

The boilers are equipped with an opening door on the right or left.

The outer shell is covered with a glass wool insulation 100 mm

thick, in turn protected by a mineral fibre fabric.

The top part of the shell is provided with hooks for lifting the

boiler.

Note: XC-K boilers are designed to operate with ON/OFF, dual

stage or modulating burner, as long as the minimum heat output

that can be reached is no lower than the value indicated on the

technical data plate.

The boilers are provided with two ½” attachments for conduits

with an inside diameter of 15 mm (suitable to house 3 bulbs

each).

The shell has holes at the sides for the cable glands of the

power, pumps, burner cables and those of any other auxiliary

device.

2

TECHNICAL FEATURES

AND DIMENSIONS

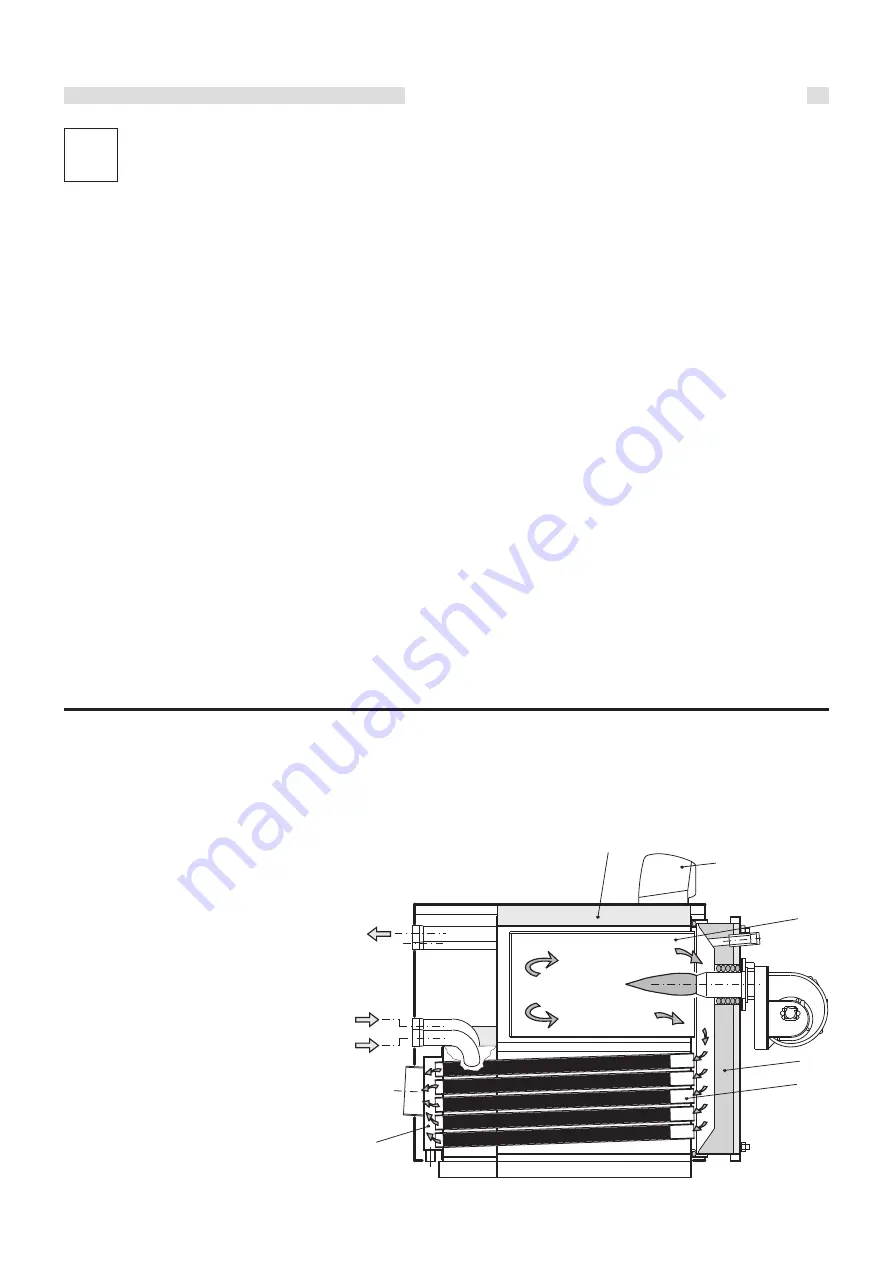

2.2 - MAIN COMPONENTS

XC-K boilers are equipped with a blind cylindrical furnace, in

which the central flame of the burner is reversed peripherally

towards the front. When the combustion gases have reached

the front part, they are sent through the door into the tubes of

the third pass to reach the rear flue gas chamber and then the

chimney.

The combustion chamber is always pressurised while the burner

is operating, within the power range of the boiler.

For the value of this pressure, see the tables

on pages 8÷10, in the column “Flue gas side

pressure drops”.

The chimney must be calculated so that

no positive pressure is detected

at its base.

1

Furnace

2

Smoke pipes with smoke diverters

3

Door with flame sight glass

4

Smoke chamber

5

Body insulation

6

Panel board

M Flow

Rbt Low temperature return

Rat High temperature return

fig. 1

1

2

3

6

5

4

M

Rat

Rbt