Checking tires for tread wear

All the tires have tread wear indicators (“ ” marking)

between the tread blocks. When the tread is worn flush

with the tread wear indicators, it means that the tread

has reached a depth of about 1.6 mm. If the tread

is worn flush with any of the tread wear indicators,

replace the tire with a new one. If replacement of a tire

is needed, both the front tires or rear tires should be

replaced as a set. Make sure new tires are the same

size as those to be replaced.

Hub nut check

CAUTION

A loose hub nut can be dangerous. In the worst

case, the wheel comes off the truck, causing the

truck to tip over.

Check the hub nuts for looseness. All hub nuts

should be tightened to the specified torque.

Hub nut tightening torque

Front wheels

Rear wheels

128 – 190 N-m

(13 – 19.4

kgf-m)

(94 – 140 ft-lbs)

Single and doubles tires:

471 – 549 N-m (48 – 56 kgf-m)

(347 – 405 ft-lbs)

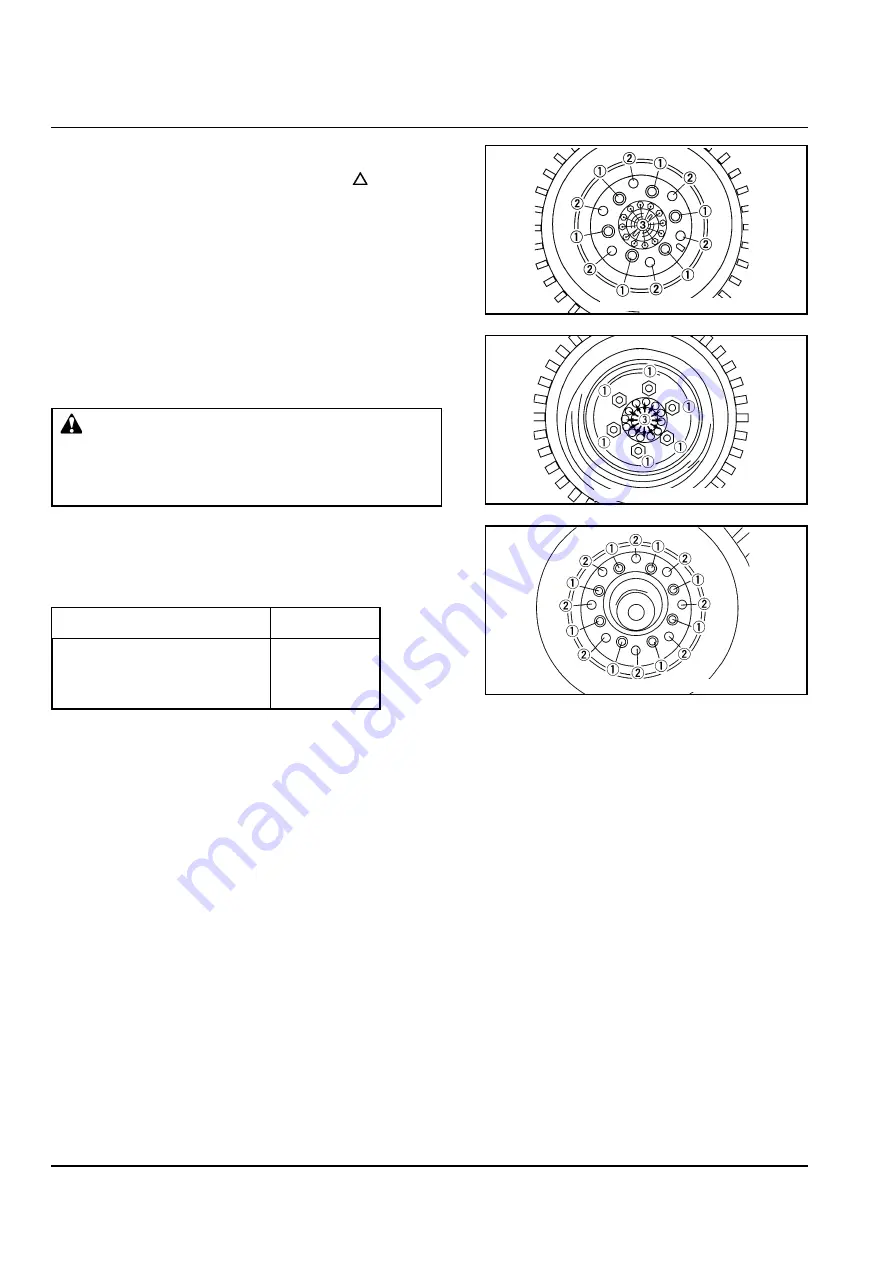

Tightening order for double tires

Double tires are installed by locking the inner tire rim

with inner hub nuts (square nuts) and then by locking

the outer tire rim with outer hub nuts (hex. nuts).

First, tighten the inner nuts (square nuts) in a

diagonal order to the specified torque and then

tighten the outer nuts (hex. nuts) in the same manner

as above.

Tightening drive shaft mounting bolts

If any loose bolt is found, retighten it to the following

torque:

96 – 111 N-m (9.8 – 11.3 kgf-m) (71 – 82 ft-lbs)

①

Hub nuts

②

Rim connecting bolts

③

Drive shaft mounting bolts

1.5- to 2.5-ton (front wheel)

3- to 3.5-ton (front wheel)

Rear wheel

4-4

PREOPERATIONAL CHECKS

Summary of Contents for FD20 Series

Page 51: ...MEMO...

Page 91: ...MEMO...

Page 139: ...MEMO...

Page 156: ...CONTENTS 0 9 6 2 A E 6 2 E L 6 3 L R 6 4 R U 6 5 6 1 6 INDEX...