UM621N User Manual

UC-00-M51 EN R1.0

Clean

13

5

Clean

DO NOT use alcohol or other organic solvents to clean, which may lead to soldering

flux residues flooding into the shielding shell, causing mildew and other problems.

6

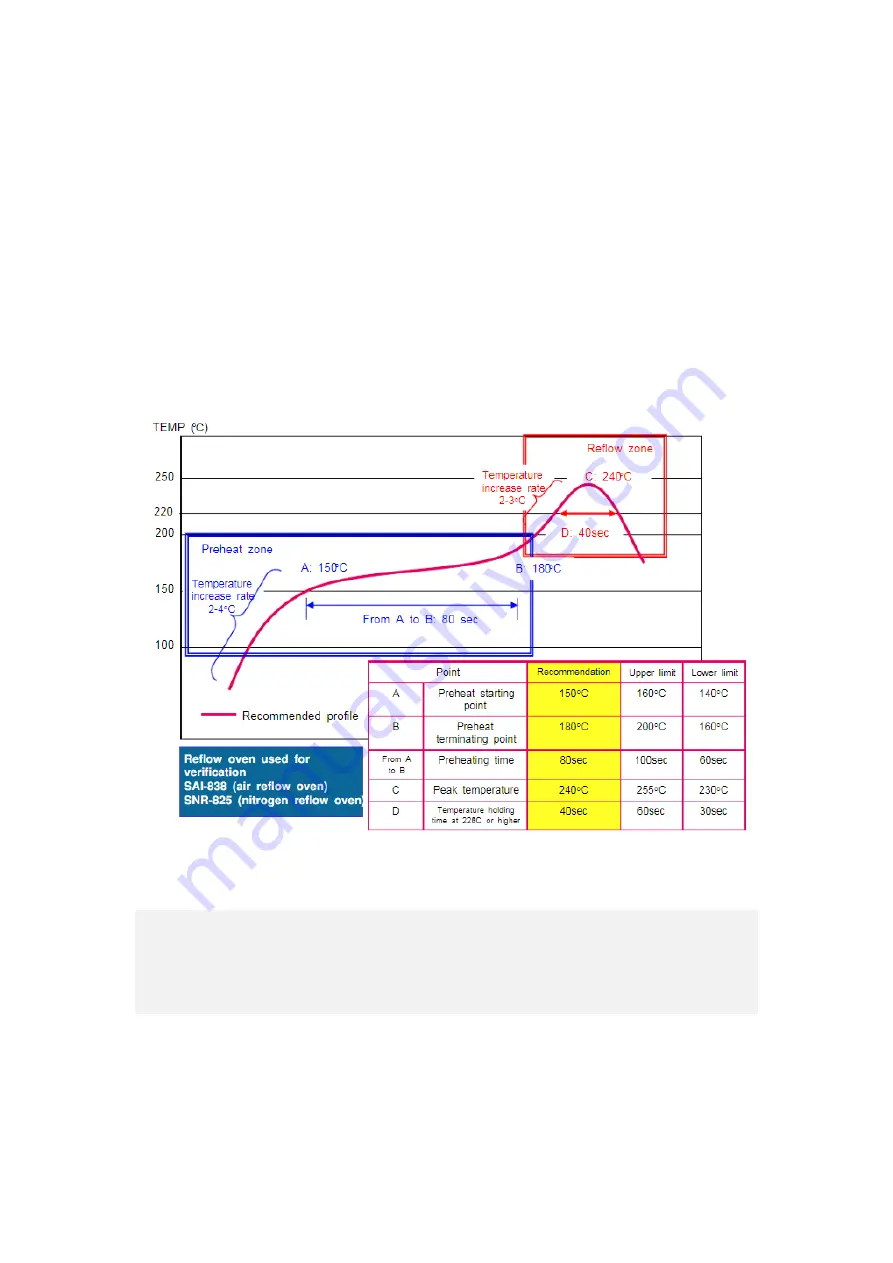

Reflow Soldering

In order to avoid the device falling off, the module should be placed on the top of the

main board during soldering. Reflow soldering temperature curve is recommended as

shown in figure 6-1 below (M705-GRN360 is recommended for solder paste).

Note: The module can only be soldered once.

Figure 6-1 Reflow Soldering Temperature Curve

Note: The apertures in the stencil need to meet the customer's own design

requirements and inspection specifications, and the thickness of the stencil should be

above 0.15 mm. It is recommended to be 0.18 mm.