- 8 -

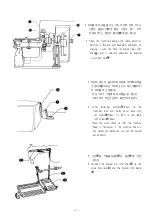

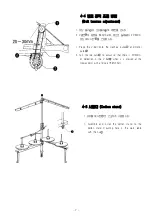

4-6 급유방법 (Lubrication)

☞

처음 미싱을 사용하는 경우, 또는 장시간 사용하지

않았을 경우는 필히 급유하여 주십시오.

☞

윤활유는 유니콘 지정 오일을 사용하여 주십시오.

1. 밑실카바①를 열고 유량계창②의 중앙까지 윤활유를

넣습니다.

2. 침봉붓싱(상) 급유구멍③에 1주일에 1회 1~2방울

급유합니다.

3. 베드 기름받이 앞에 고여 있는 기름은 때때로

배유나사⑤를 분해하여 기름을 빼냅니다. 기름을

빼낸후 배유나사⑤를 조립합니다.

4. 베드 기름받이④ 뒤에 고여 있는 기름은 때때로

천 등으로 닦아줍니다.

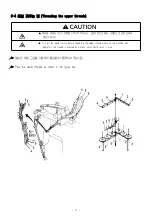

5. 풀리를 회전하여 나사⑦가 윗방향에 있는 상태에서

나사⑦를 풀고, 기름탱크에 가득히 기름을 채웁니다.

윤활유가 기름탱크 중심선⑨ 이하로 되면 상축

안으로 윤활유가 들어가지 않게 되어서, 급유가

불완전하게 되므로, 필히 기름량은 탱크중심선

위로 보충하여 주십시오.

6. 나사⑦를 조립합니다.

☞

The sewing machine should always be lubricated and the oil supply replenished before it is used for the first time,

and also after long periods of non-use.

☞

Use only the lubricating oil specified by Unicorn.

1. Open the front cover①, and then fill with oil until the oil level reaches the point in between the reference lines on

the oil gauge②.

2. Add 1-2 drops of oil once a week to needle bar bracket lubrication hole③.

3. Periodically loosen the oil drain screw⑤ to drain out any oil which collects in the front bed oil sump.

After draining the oil, tighten the oil drain screw⑤.

4. Periodically wipe away any oil which collects in the rear bed oil sump④ with a cloth.

5. Turn the machine pulley, so that screw⑦ is facing upward, and then remove the screw⑦ and fill the oil tank.

If the level of lubricating oil drops below the middle reference line⑨on the oil tank, no oil will be drawn into the

upper shaft, and the upper shaft will thus not be lubricated sufficiently.

Be sure to maintain the lubricating oil level at a level above the center reference line.

6. Attach the screw⑦.

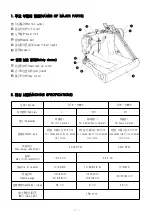

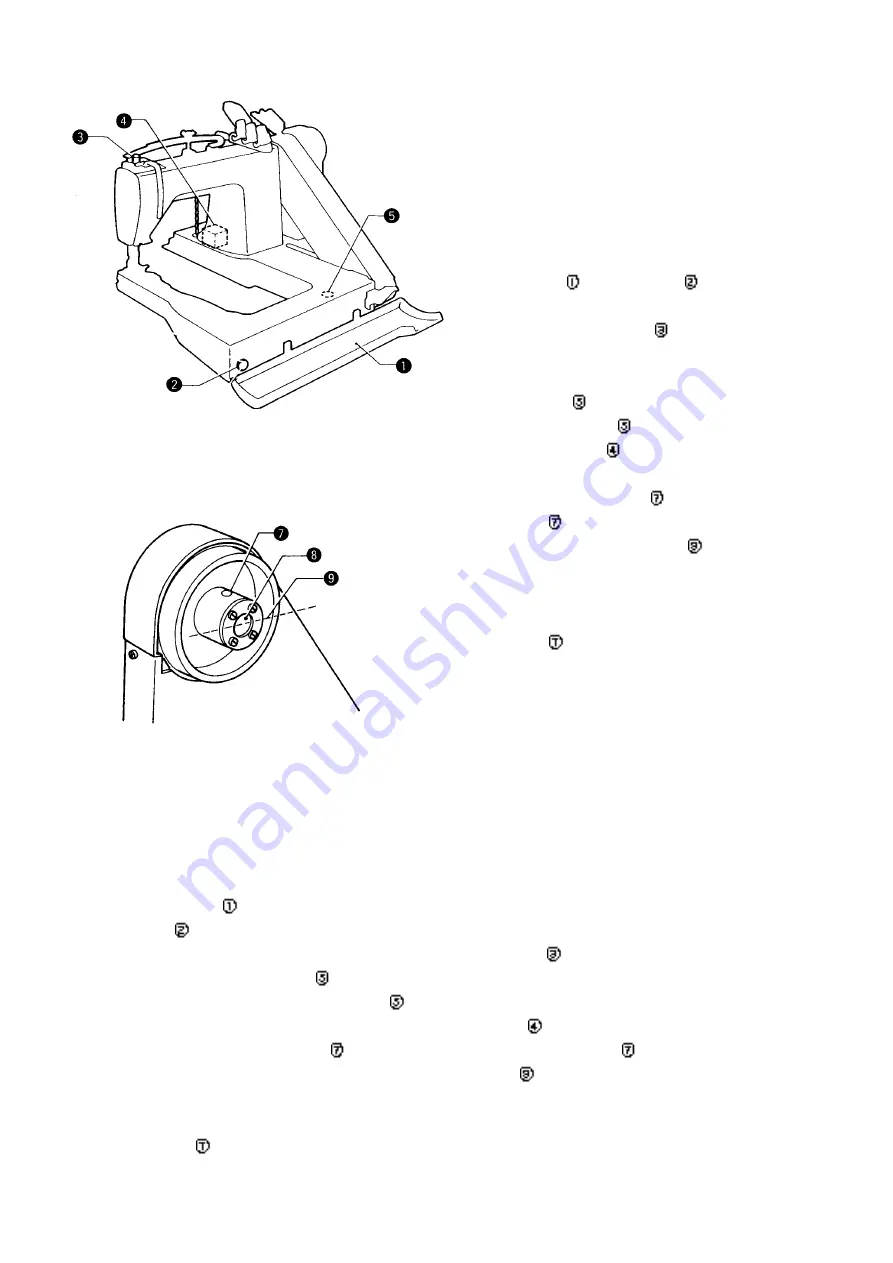

Summary of Contents for DT6-H892?3

Page 2: ......

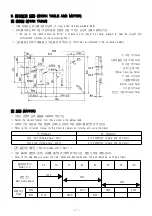

Page 4: ...5 off A S 31 2 40 25 OFF A S A S...

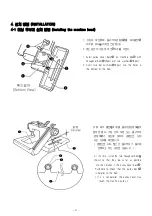

Page 32: ...22 10 1 13 19 2 9 16 16 20 16 3 13 19 4 19 13...