- 3 -

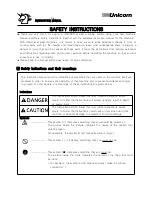

1. 발판조작 / Pedal operation

올바른 사용방법 / OPERATION

★ 발판을 가볍게 ①까지 밟아서 저속재봉을 확인해주십시오. ②까지 밟으면 고속재봉을 합니다.

★ 발판을 앞으로 밟은후 중립(발판에서 발을 때었을때)③이 되면 바늘이 침판에서 내려간 위치에서 정지하는 것을 확인해주십시오.

(침하정지를 설정한 경우)

★ 발판을 ④ 쪽으로 역으로 밟으면(또는 발판을 ④ 쪽으로 역으로 밟은후, 중립③으로 돌아온 경우) 사절후 바늘이 침판에서 올라간

위치에서 정지합니다.

★ Treadle the pedal lightly to position① and that the machine sews at low speed. Then treadle the pedal to

position② to sew at high speed.

★ After treading the pedal, return it to neutral③ (simply rel ease the pedal) to stop the machine with the needle

tip below the needle plate(when the needle position switch is set to the needle down position).

★ B ack-treadl e the pedal to position④ and release it to neutral to trim the thread and stop the ma chine with the

needle raised above the needle plate.

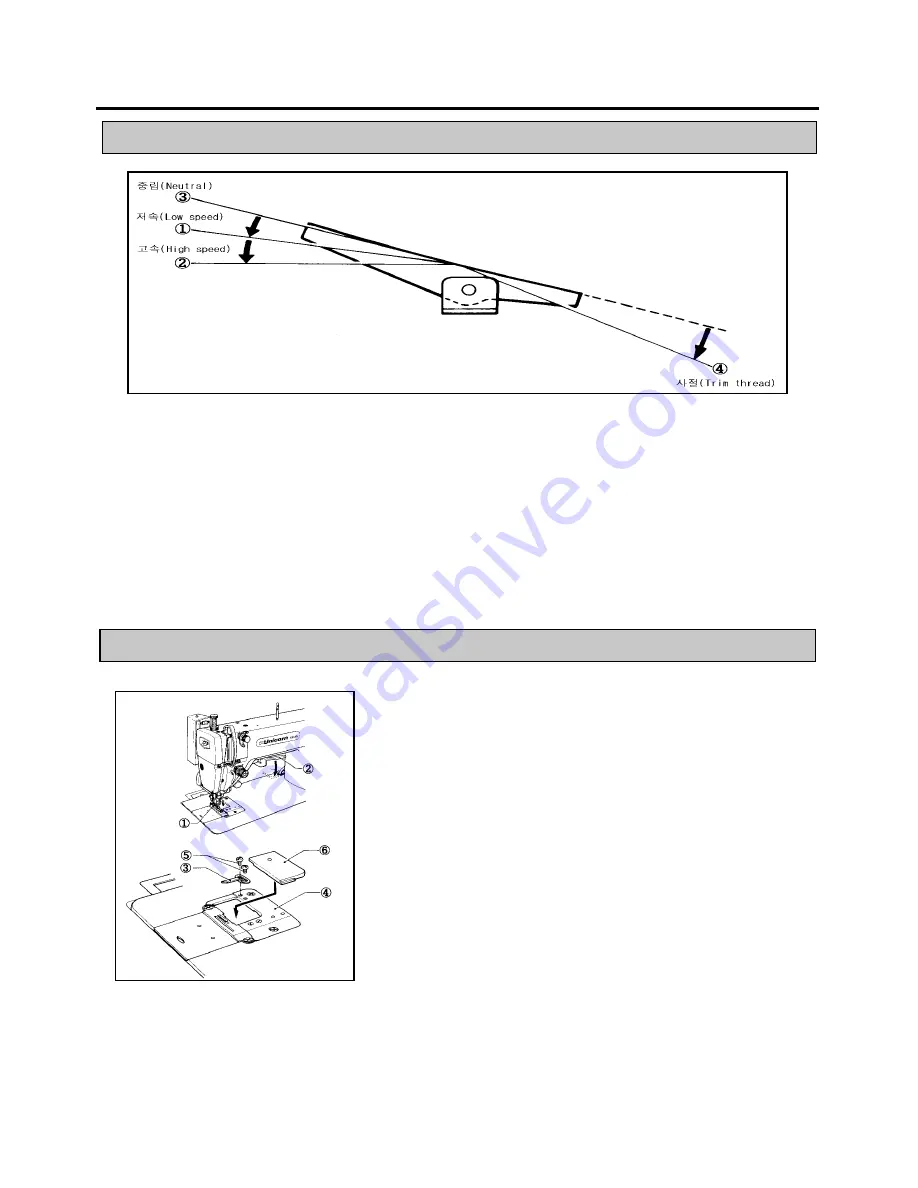

2. 윗칼조작 / Upper knife operation

★윗칼①을 작동시킬 경우는 레버②를 내려주세요.

윗칼①은 미싱운전과 동시에 동작합니다. 윗칼①을 고정시킬 경우는

레버②를 올려부세요. 윗칼①은 올라갑니다.

※ 레버②의 조작은 반드시 미싱을 정지시킨후 해주세요

★ To operate the upper knife①, l ower the upper knif e set lever②.

The upper knif e① will now operate in sync with the operation of

the machine. To stop the upper knife①, raise the upper knife set

l ever②. The upper knife① will rise.

※ Stop the machine before operating the upper knife set lever②.

ꁴ

안내U의 설치방법 (Attaching the sewing scrap guide(U)

★ 짤려진 천조각이 베드이 하측으로 떨어짐이 어려울 때는, 부속의

안내U③을 보조침판④에 죔나사⑤로 설치해주세요.

★ When it is dif ficult f or scraps to drop below the bed, attach the

supplied sewing scrap guide(U)③ to the auxiliary needle plate④

using the screw⑤.

ꁴ

침판덮개의 설치방법 (Installing the needle plate cover)

★ 재단한 천조각을 베드 아래면에 떨어뜨릴 필요가 없는 경우는, 부속의 침판덮개⑥를 보조침판④에 끼워서

사용해주세요.

★ If it is not necessary to collect scraps below the bed , fit the sup plied need le plate cov er⑥ over the aux iliary

needle plate④ .

Summary of Contents for LS2-H530

Page 2: ......

Page 4: ...5 off A S 34 2 40 25 OFF A S A S...

Page 26: ...16 4 4 8 8 8 8 4 4 4 6 6 6 2...

Page 28: ...18 4 4 1 4 4 8 8 8 6 6...

Page 30: ...20 6 6 6 6 puff 8 11 14 4 13 11 14 11...

Page 32: ...22 6 1 13 6 11 11 11 11...

Page 34: ...24...