- 6 -

올바른 사용방법 / OPERATION

7. 사조자 / Adjusting the thread tension

★ 밑실의 상태는 실 끝을 잡았을 때, 보빈케이스가 저절로 흘러내리지 않을 정도로 약하게 나사①를 돌려서 조절해주십

시오.

★ 윗실상태는 노루발을 내린 후, 나사②를 돌려서 위 그림과 같이 조절해주십시오.

★ 사절 후 바늘 끝에 남은 실의 길이는 35~40 mm가 되도록 조절나사③을 돌려 조절해주십시오.

★ Adjust the bobbin thread tension by turning the adjusting screw ① so that the bobbin case will not

slip down of its own weight when suspended from the bobbin threa d.

★ Lower the presser foot and adjust the needle thread tension by turning the adjusting screw ② as

shown in figure above.

★ Adjust the adjusting screw ③ so that the length of the needle thread af ter thread trimming is about

35 ~ 40 mm.

ꁴ

실잡이 스프링 (Thread take-up spri

ng)

★ 실 잡이 스프링의 동작범위는 7~10mm가 표준입니다. 또 실잡이

스프링의 강함은 25~30g가 표준입니다.

★ 실 잡이 스프링의 작용범위를 조절하는 것은 고정나사④을 풀고,

윗실조절기를 돌려주십시오.

★ 실 잡이 스프링의 강함을 바꾸는 것은 사조자봉⑤의 홈에 드라이버

끝을 넣고 돌려서 조절해주십시오.

★ The standard operation range of the thread take-up spring is

about 7~10mm. The standard tension at this time is 25~30g.

★ To adjust the operation range of the thread take-up spring, loosen the set screw

④ and turn the thread

tension

bracket assembly.

★ To adjust the tension of the thread take-up spring, fit a screwdriver into the slot, and turn the tension stud

⑤ as appropriate.

8. 땀 길이의 조절 / Adjusting the stitch length

★ 역전핸들①을 중앙의 위치까지 누르고, 다이얼②의 숫자를 상부의 핀③에 맞추고

나서 역전핸들①을 놓아주십시오.

※ 숫자가 클수록 이송량은 많게 됩니다. 최대 땀은 5mm입니다. 단 역전재봉은

약 3mm입니다

ꁴ

역전장치

역전핸들①을 누르면 천이 역 이송됩니다. 놓으면 복원해서 정 이송으로

되는 자동복원식입니다.

★ Push the reverse lever ① halfway down, turn the dia l ② until the desired

number is aligned with the pin ③ at the top, and rel ease the reverse lever ①.

※ The larger the number, the longer the stitch w ill be. Maximum stitch leng th is 5 m m.

Fo r rev erse stitching , it is 3 m m

ꁴ

Reverse sewing device

The reverse sewing device is of the automatic-resetting type. T he material wil

be fed backward when the reverse lever ① is pressed, and forwa rd a gain when it is released.

Summary of Contents for LS2-H530

Page 2: ......

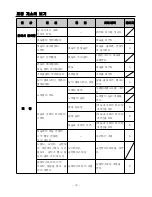

Page 4: ...5 off A S 34 2 40 25 OFF A S A S...

Page 26: ...16 4 4 8 8 8 8 4 4 4 6 6 6 2...

Page 28: ...18 4 4 1 4 4 8 8 8 6 6...

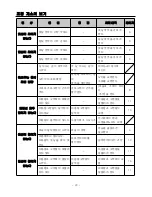

Page 30: ...20 6 6 6 6 puff 8 11 14 4 13 11 14 11...

Page 32: ...22 6 1 13 6 11 11 11 11...

Page 34: ...24...