- 13 -

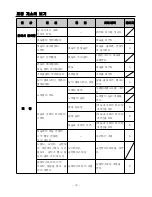

8. 위치검출기의 조정 / Adjusting the synchronizer

조 정 / ADJUSTMENT

1. 위치검출기는 2개의 소자로 침위치를 검출합니다. 또 침하신호와 사절신호를 하나의 소자로 제어합니다.

2. 전원스위치를 넣고, 침하정지위치에서 미싱을 정지했을 때 침판상면에서 침고정나사 하단까지 18~22m에

정지합니다.

★조정이 필요한 경우는 전원스위치를 끊어주십시오.

ꁴ

침상정지위치의 조정

★2개의 죔나사①를 풀어주십시오.

★죔나사①를 미싱풀리의 회전방향에 이동시키면 침봉②가 높은 위치에서 정지합니다.

ꁴ

침하정지위치의 조정

1. 발판을 밟은 후 중립(발판을 놓는다)으로 해주십시오.

2. 침판상면에서 침고정나사 하단까지 18~22mm로 정지하는 것을 확인해주십시오.

3. 죔나사③를 풀고, 위치검출기④을 이동시켜서 조정해주십시오. ※ 다시 침상정지위치를 확인해주십시오.

★풀리를 설치할 때 풀리단면과 위치검출기의 간격을 0.5mm로 해주십시오

주) 침하정지위치는 조정하지 말아주십시오.

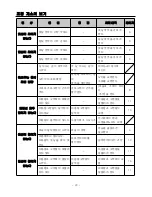

★ The synchronizer includes the two elements which are used to detect the needle position. One of

these elements is used to control the down needle stop position signal and the thread trimming signal.

When the power is turned on and the machine is sto pped i n the dow n needle stop position, there

sho uld be a 18~22 mm gap between the upp er surface o f the needle p late and the bo ttom edg e of

the needle set screw . When the m achi ne is stop ped in the up need le sto p po sition , there should be a

9.5~11.5 m m g ap betw een the upper surface of the need le plate and the needle tip with thin o r

m ed ium materials, o r a 10~ 12 m m g ap w ith thick m aterials.

If a djustment of needle stop position is necessary, refer to the procedure below.

ꁴ

Adjustment of the up needle stop position

1. Turn off the power.

2. Loosen the two screws ①.

3. To raise the needle bar ②, rotate the screws ① in the direction of normal pulley rotation.

To lower the needle bar ②, rotate the screws ① in the opposite direction.

※ The synchronizer is adjusted at the factory. Do not remove the synchronizer after removing the

machine pulley.

When a ttaching the pulley, set a 0.5 mm gap between the pulley edge and the synchronizer.

Do not adjust the down needle stop position.

Summary of Contents for LS2-H530

Page 2: ......

Page 4: ...5 off A S 34 2 40 25 OFF A S A S...

Page 26: ...16 4 4 8 8 8 8 4 4 4 6 6 6 2...

Page 28: ...18 4 4 1 4 4 8 8 8 6 6...

Page 30: ...20 6 6 6 6 puff 8 11 14 4 13 11 14 11...

Page 32: ...22 6 1 13 6 11 11 11 11...

Page 34: ...24...