- 15 -

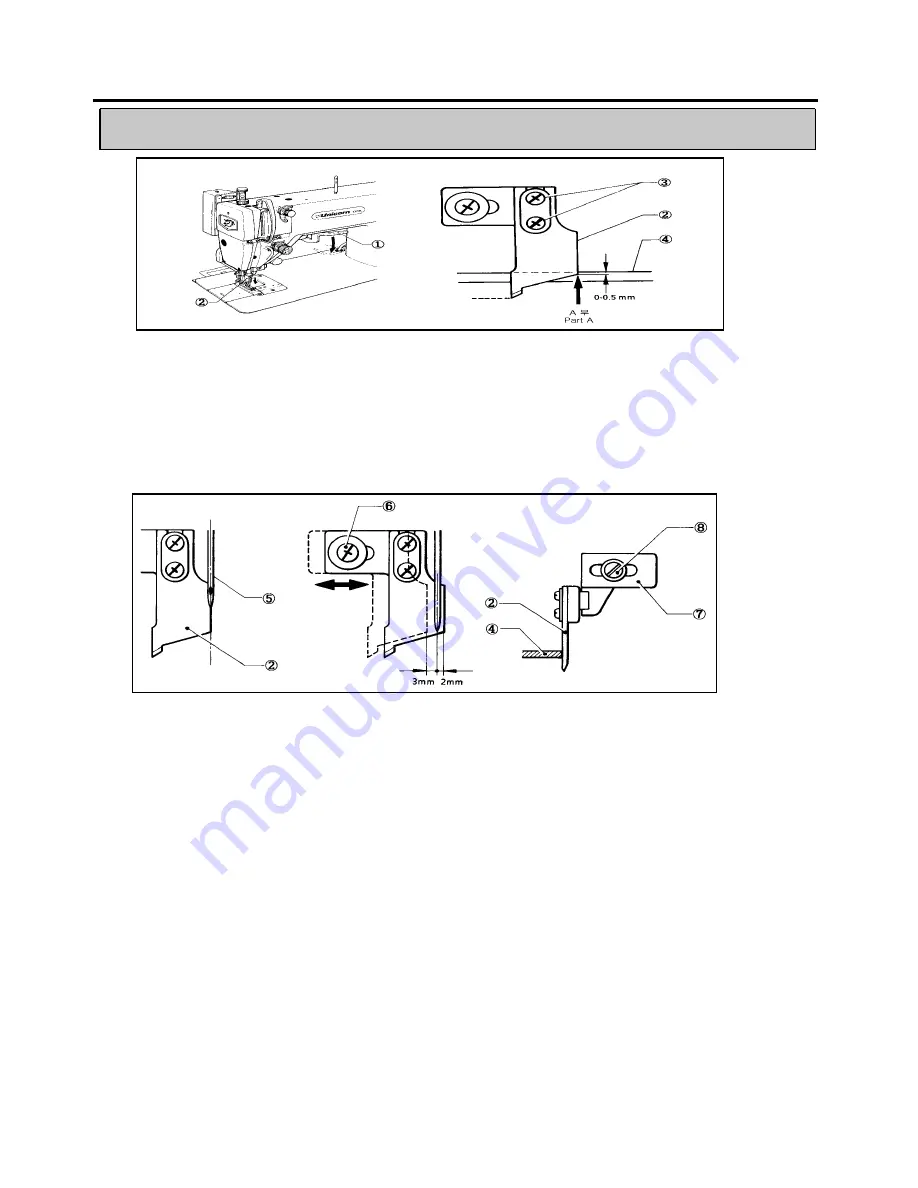

10. 윗칼의 조정 / Adjusting the upper knife

조 정 / ADJUSTMENT

1. 윗칼설치조정 / Upper knife installation adjustment

(1) 윗칼세트레버①을 내리고, 미싱풀리를 돌려서 윗칼②을 최하점으로 해주세요.

(2) 2개의 죔나사③를 풀고, 윗칼②의 A부가 침판④ 상면에서 0~0.5mm 내려간 위치에서 죔나사③를 체결해주세요.

(1) Lower the upper knife set lever①, and turn the machine pulley to set the upper knife② at the

bottom position.

(2) Loosen the two set screw③, and then tighten them so that part A of the upper knife② is set

a t a distance 0~0.5mm below the top of the needle plate④.

2. 윗칼 전후위치의 조정 / Upper knife front-back position adjustment

(1) 다이얼 눈금을 0으로 해주세요.

(2) 윗칼 표준위치는 윗칼② 뒤쪽 끝이 바늘⑤ 중심의 앞측에 2mm입니다.

윗칼 전후위치의 조정범위는, 죔나사⑥를 풀고, 바늘⑤ 중심에서 윗칼② 뒤쪽 끝이 앞측에 2mm, 뒤측에 3mm로

조정할 수 있습니다.

(1) Set the upper feed scale to 0.

(2) The back edge pf the upper knife② should be aligned with the needle⑤ center. The upper knife

can be adjusted by loosening the screw⑥ and moving the knife within a range of 2 mm forward to

3 mm backward.

3. 윗칼 좌우위치의 조정 / Upper knife right-left position adjustment

․

칼홀더⑦의 죔나사⑧를 풀어, 윗칼②의 측면을 침판④측에 가볍게 밀고, 죔나사⑧를 체결해주세요.

※ 윗칼②을 침판④에 너무 세게 누르면 윗칼②이 올라가지 않는 경우가 있기 때문에, 조정 후 윗칼세트레버①를

상하 움직여서 윗칼②이 부드럽게 움직이는 것을 확인해주세요.

․

Loosen the set screw⑧ in the knife holder⑦ and set the side of the upper knife② lightly against

the side of the needl e plate④. Tighten the screw⑧.

※ If the upper knife② is forced too hard against the needle pla te④, the upper knife②may be

prevented from rising. After adjustment, raise and lower the upper knife set l ever① to make sure the upper

knife② moves smoothl y up and down.

Summary of Contents for LS2-H530

Page 2: ......

Page 4: ...5 off A S 34 2 40 25 OFF A S A S...

Page 26: ...16 4 4 8 8 8 8 4 4 4 6 6 6 2...

Page 28: ...18 4 4 1 4 4 8 8 8 6 6...

Page 30: ...20 6 6 6 6 puff 8 11 14 4 13 11 14 11...

Page 32: ...22 6 1 13 6 11 11 11 11...

Page 34: ...24...