- 20 -

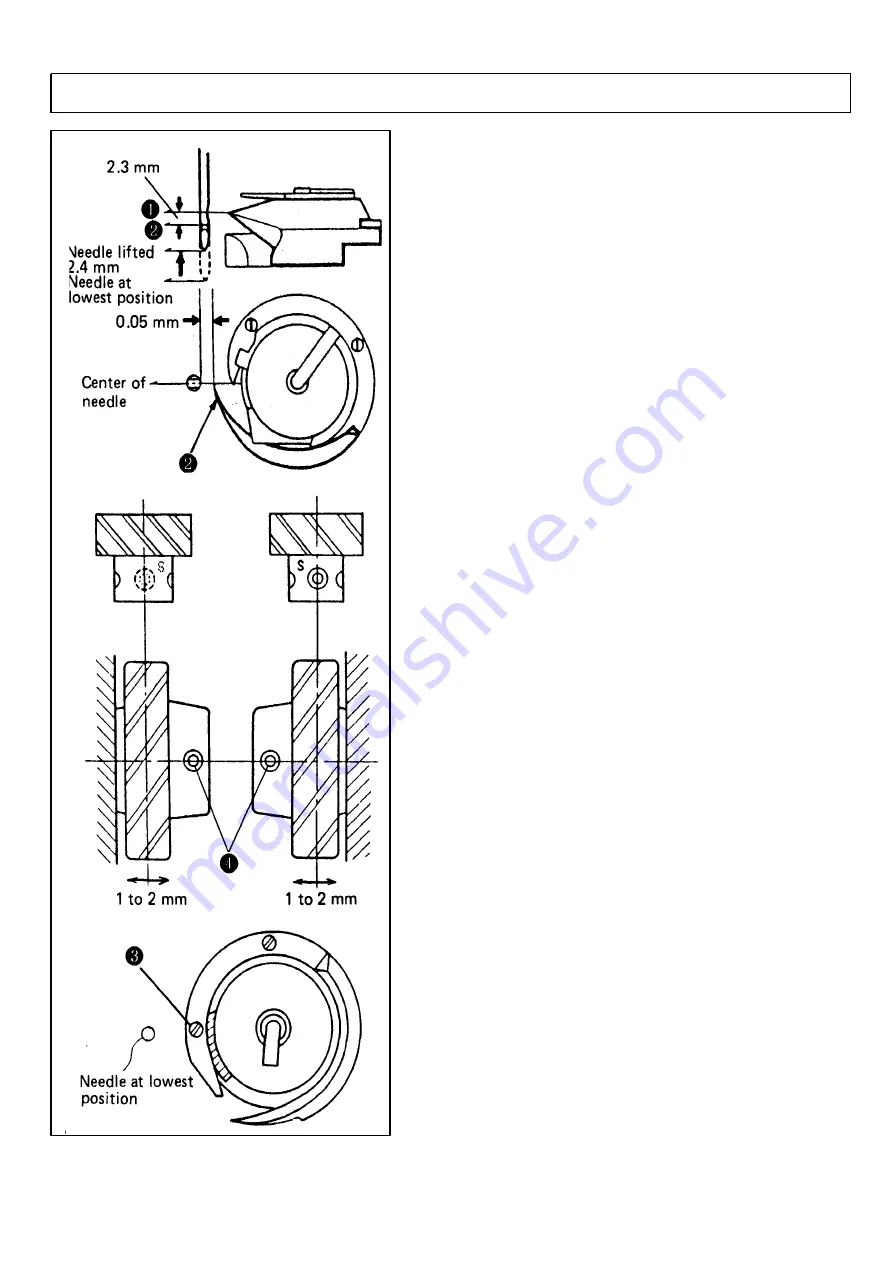

13.가마와 바늘의 타이밍 / TIMING ADJUS TM ENT FOR ROTATING HOOK AND NEEDLE

☞

땀수조절 다이얼을 돌려 6애 맞춥니다.

☞

그림과 같이, 풀리를 돌려 바늘을 최하점에서 2.4mm

상승시켰을 때의 가마와 바늘을 위치는 아래와

같습니다.

바늘구멍①의 상단은 가마끝②보다 아래에 위치

가마끝은 바늘과 가마의 중심선과 일치

가마끝과 바늘의 측면 틈은 : 0.05mm

☞

가마와 바늘의 위치를 수정할 때는 노루발과

침판과 톱니를 떼어낸 상태에서 하는 것이

좋습니다.

☞

Set stitch length adjustin g dial "6".

☞

When the needle is lifted 2.4mm from its lower

most position, the rotating hook an d the needle

should be located at the following location s;

The upper edge of needle eye① should be below

the hook point②.

The hook poin t should be located at the center of

needle axis.

Gap between the hook poin t and the side face of

needle should be 0.05mm.

☞

Easy adjustment can be made by removing the

presser foot, throat plate, and feed before

adjustment.

가마 끝② 의 위치 결정

☞

바늘이 최하점의 위치일때 오른쪽 기어(小)의

S나사는 정면에, 외쪽 기어(小)의 S나사는 뒤쪽에

가도록 큰 기어와 맞춥니다.

☞

가마축을 맞추고 S나사를 단단히 죄어줍니다.

☞

가마 위치의 기준은 바늘의 최하의 위치일때 가마

나사③는 바늘의 거의 옆에 위치해 있습니다.

☞

바늘과 가마 위치의 미세조정은 큰 기어의

나사④를 풀고, 큰 기어를 축방향으로 1~2mm의

범위에서 움직여서 조정합니다.

Positionin g th e h ook poin t②

☞

With the needle at lowermost position, mesh the

right hand driving gear(small) with the large

gear so that "S" screw is located at front, and

mesh the left hand driving gear(small) so that

"S" screw is located at rear.

☞

Tighten "S" screw on to the set contact of hook

shaft.

☞

Guide of rotating hook position

When the needle is at its lowermost position, th e

screw③ in rotating hook is nearly in line with

the needle.

☞

To make fine adjustment of hook an d needle

motion, loosen screw④ in driving gear(large) and

move th e driving gear(large) 1~2mm in the axial

direction.

Summary of Contents for LT2-H650

Page 2: ...1...

Page 4: ...5 off A S 44 2 40 25 OFF A S A S 3...

Page 8: ...UNICORN A S 1 2 3 7 3 2 1...

Page 32: ...31 p28 p27 p27 p30 p29 p29 p14 p14 p14 1 p18 p17 p17...

Page 34: ...33...