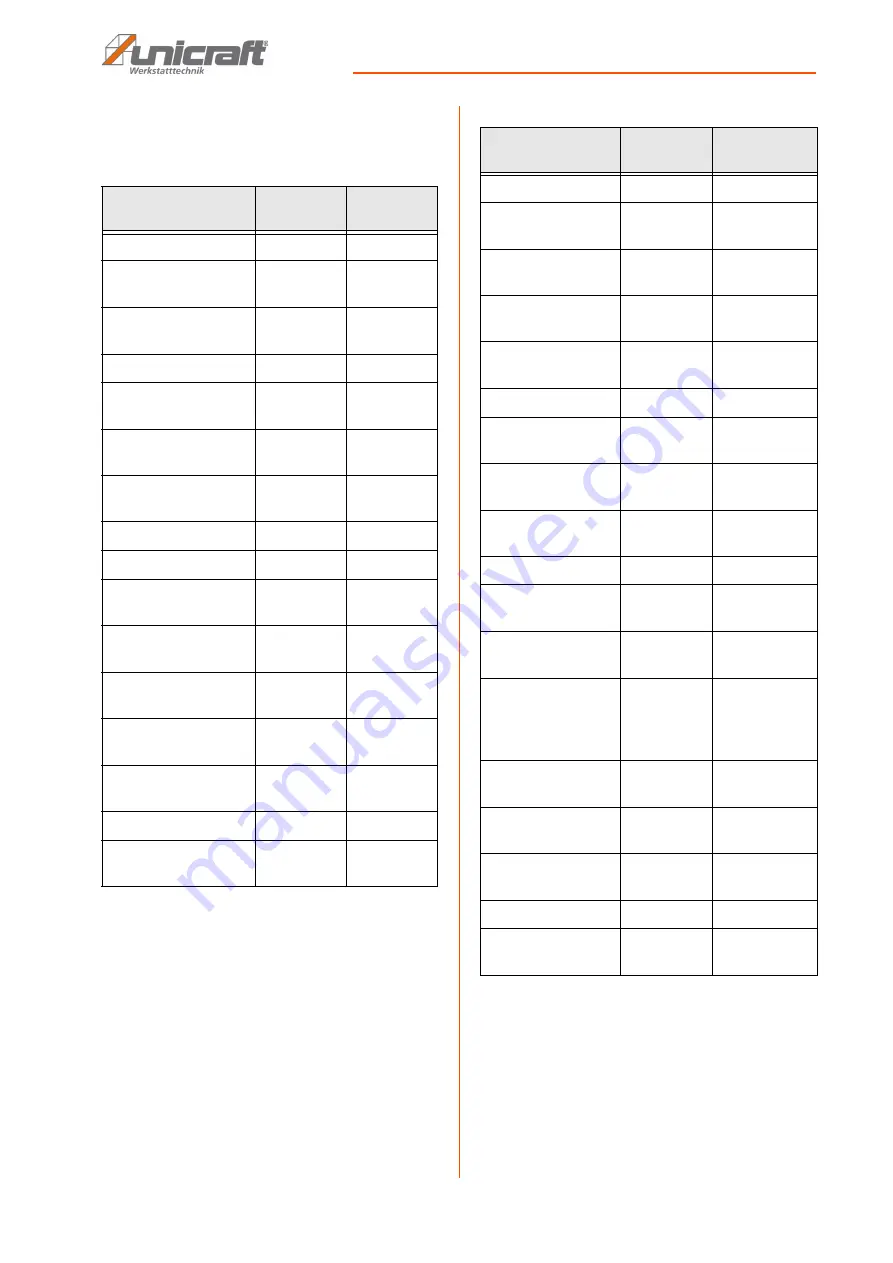

Technical Data

PG-E-Series | Version 2.08

7

4

Technical Data

4.1 Table

Model

PG-E 30

SRA

PG-E 40

SRA

Voltage

230 V

230 V

Emergency output

LTP

2,8 kW

3,8 kW

Continuous output

COP

2,5 kW

3,3 kW

Fuel

Petrol

Petrol

Starter

Manual

start

Manual

start

Running time

at 50% load

12,5 hours

14 hours

Running time

at 100% load

9,5 hours

9,5 hours

Tank capacity

15 Liter

15 Liter

Sound pressure level

75 dB(A)

75 dB(A)

Weighted sound

power level (L

WA

)

95 dB(A)

95 dB(A)

Socket type

2x 230V

shockproof

2x 230V

shockproof

Generator IP degree

of protection

IP 23

IP 23

Socket IP degree of

protection

IP 44

IP 44

Dimensions (LxWxH)

[mm]

595x460x

500

595x460x

527

Weight

45 kg

50 kg

Motor oil volume

min./max.

0,25 - 0,6

liter

0,25 - 0,6

liter

Model

PG-E 60

SEA

PG-E 80 TEA

Voltage

230 V

230V/400 V

Emergency output

LTP 230V

5,5 kW

2,5 kW

Continuous output

COP 230V

5,0 kW

2,3 kW

Emergency output

LTP 400V

7,0 kW

Continuous output

COP 400V

6,5 kW

Fuel

Petrol

Petrol

Starter

Manual

start

Manual start/

Electric starter

Running time

at 50% load

16 hours

13 hours

Running time

at 100% load

8,2 hours

8,5 hours

Tank capacity

25 Liter

25 Liter

Sound pressure

level

76 dB(A)

76 dB(A)

Weighted sound

power level (L

WA

)

96 dB(A)

96 dB(A)

Socket type

2x 230 V

shockproof/

1x 230V

CEE 32A

2x 230 V

shockproof/

1x 400V CEE

16A

Generator IP degree

of protection

IP 23

IP 23

Socket IP degree of

protection

IP 44

IP 44

Dimensions

(LxWxH) [mm]

700x526x

580

700x526x

580

Weight

81 kg

88 kg

Motorö oil volume

min./max.

0,55 - 1,1

liter

0,6 - 1,2

liter

Summary of Contents for 6706030

Page 45: ...Notes PG E Series Version 2 08 45 14 Notes ...

Page 46: ...www unicraft de ...