Operation

ESW 900 | Version 2.04

9

The working area has to be protected against fire and

explosions and free from corroding and toxic sub-

stances.

Dangerous goods like molten, toxic or radioactive mate-

rial must not be moved with the wire rope hoist.

The appliance must not be used in the open air if it is

raining.

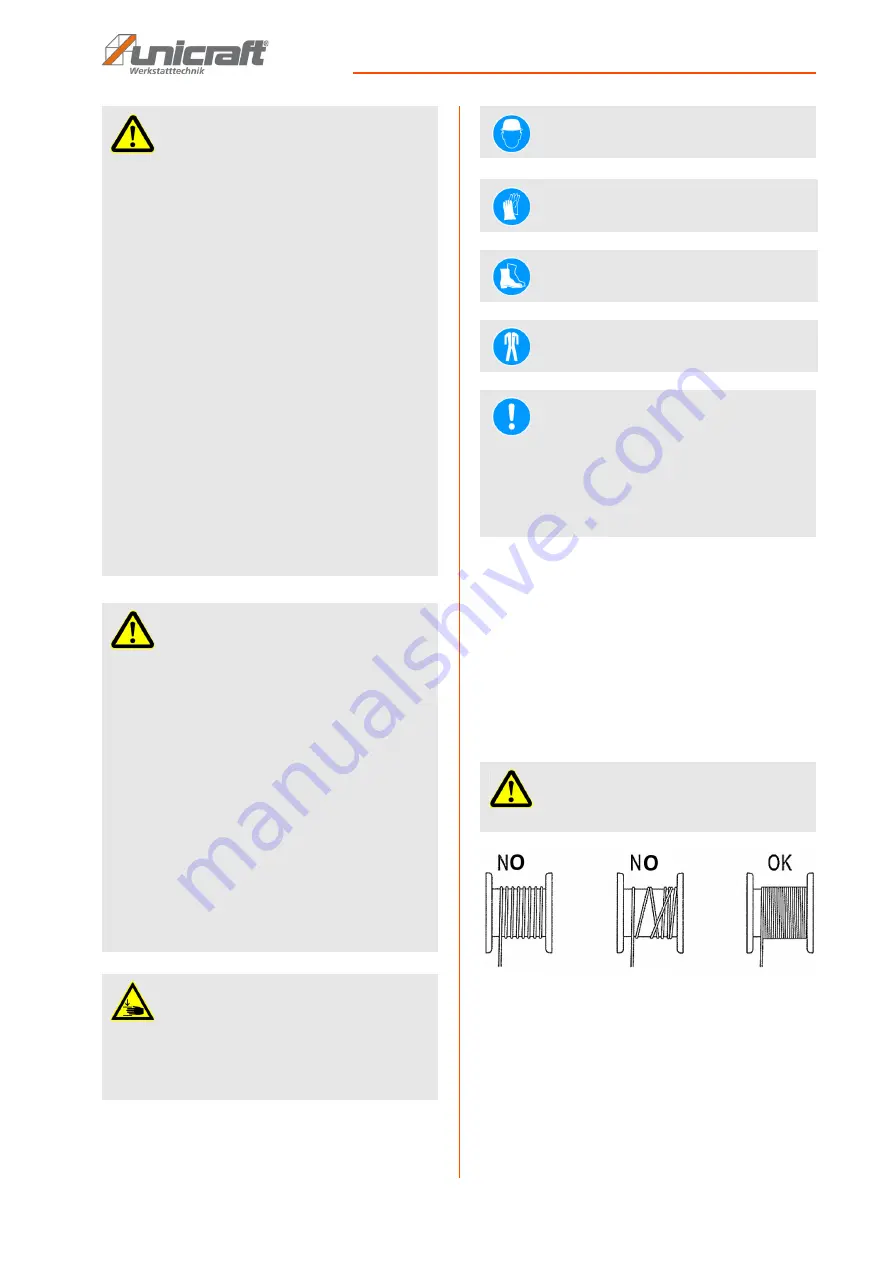

The cable has to be under a light tension for winding.

Hold the rope with gloves in one hand and use the con-

trol button with the other hand.

Abb. 4: correct winding of the cable

DANGER!

Danger of life by crashing the load!

Falling loads can cause serious injury or death.

- Never stand, linger or work below a suspended

load.

- Loads may only be moved under supervision.

- A load must not be lifted by the wire rope hoist if it

is slipping, falling or if its component parts are not

secured firmly together.

- A rusted or damaged wire rope hoist must never be

used.

- A load lifted by the wire rope hoist should not be left

unattended.

- Care should be taken during lifting that the opera-

tor does not stand within the working range of the

load.

- When leaving the workplace, lower the load.

- Unsuitable suspension points can fail and the load

may drop. The wire rope hoist load hook should

only be secured to suitable suspension points on

the load.

- Under no circumstances may a load be subjected

to a heavy blow or collision.

ATTENTION!

- Do not carry people on the wire rope hoist.

- Do not move loads which exceed the maximum

load-bearing capacity of the wire rope hoist (see

type plate).

- Never use the wire rope hoist with damaged or

kinked cable.

- The wire rope hoist must not be used for moving

jammed or wedged loads.

- Avoid over-use of jog control (repeated short im-

pulses to the motor).

- Do not change the direction of movement sud-

denly.

- In order to prevent accidents and to minimise strain

on the wire rope hoist, never leave a heavy load

suspended for a lengthy period of time.

CAUTION!

Risk of crushing!

Injuries to hands and fingers may result from

improper use of the electric wire rope hoist.

- Never grasp the cable while the equipment is in op-

eration.

Head protection must be worn!

Use protective gloves!

Use protective boots!

Wear protective clothes!

NOTE!

- Operating personnel must be familiar with the oper-

ation and functions of the wire rope hoist and the

safety regulations pertaining to it.

- The operator is responsible for ensuring that all op-

erating personnel have had the necessary training.

ATTENTION!

Ensure that the cable is rolled up evenly.