Care, maintenance and repair

K-Series | Version 1.03

11

Control of the brake system

Brake-/Ratche tests areto be carried out as follows:

Step 1: Attach the load

Step 2: Lift the load.

Step 3: Raise and lower load at different heights.

Step 4: Test whether it is possible to hold the load in

every position.

Inspection the load chain for wear

Continuous inspection the chain hoist is a mandatory re-

quirement in accordance with DIN 685 Part 5 or UVV

BGV D8 Section 27 (VBG 8 Section 27). Check the chain

hoist is before commissioning and under normal opera-

ting conditions after approx. 200 operating hours or

10.000 load cycles, in heavy operating conditions in at

shorter intervals

The links should be checked especially at the points of

contact for wear, cracking, deformation and other da-

mage.

The chain must be replaced:

- Reduction of the nominal thickness at the contact

points by 10%

- Elongation of a limb by 3% or the chain over 11

limbs by 2,5% stiff chain links

- stiffened chain links

When changing the chain, check the chain guide and

replace if necessary.

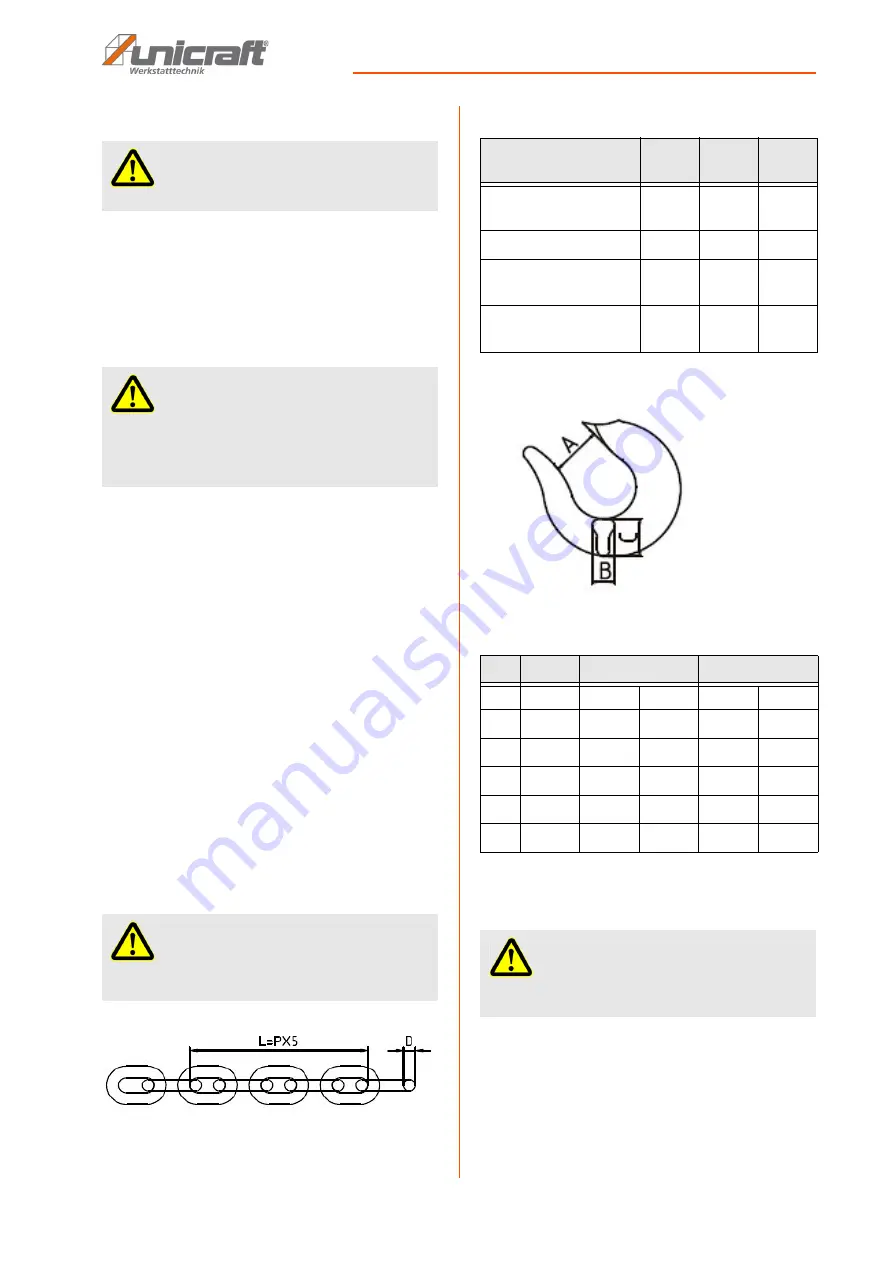

Fig. 7: Chain dimensions

Wear measurement and replace of the load hook

Fig. 8: Dimension of the hook

* Nominal values. The concrete value must be measured on the new

hook. The expansion must not be more than 5% of the measure of the

new condition.

ATTENTION!

The brake dsytem must be checked regularly!

ATTENTION!

The brake disc must be replaced if the thickness of

the pane is 2,5 mm (standard thickness 3 mm) or

less or if it is no longer possible to hold the load in

any position.

ATTENTION!

Only use the original replacement chain from the

hoist manufacturer as a replacement chain.

Model

K 1001

K 2001,

K 3001

K 5001,

K 10001

Standard chain link

Diameter D [mm]

6 8

10

D min. [mm]

5,4

7,2

9,0

Standard length inside L

[mm] (3 chain links)

90

120

150

Max. L [mm]

(Elongation to mm)

92,5

123,3

154,0

A*[mm]

B [mm]

C [mm]

Standard

Limit

Standard

Limit

1 t

30

13

12,4

21,5

20,4

2 t

33,5

21

20,0

34,3

32,6

3 t

40

25

23,8

43,8

41,6

5 t

50

32

30,4

52,5

49,9

10 t

64

40

38

60,4

57,4

ATTENTION!

Only use original parts from the hoist manufacturer

as replacement parts.

Summary of Contents for K 1001

Page 18: ...www unicraft de...