16

KW-Series | Version 1.03

Care, Maintenance and Repair

Visual inspection

Wear measurement and renewal of load hook and lifting eye

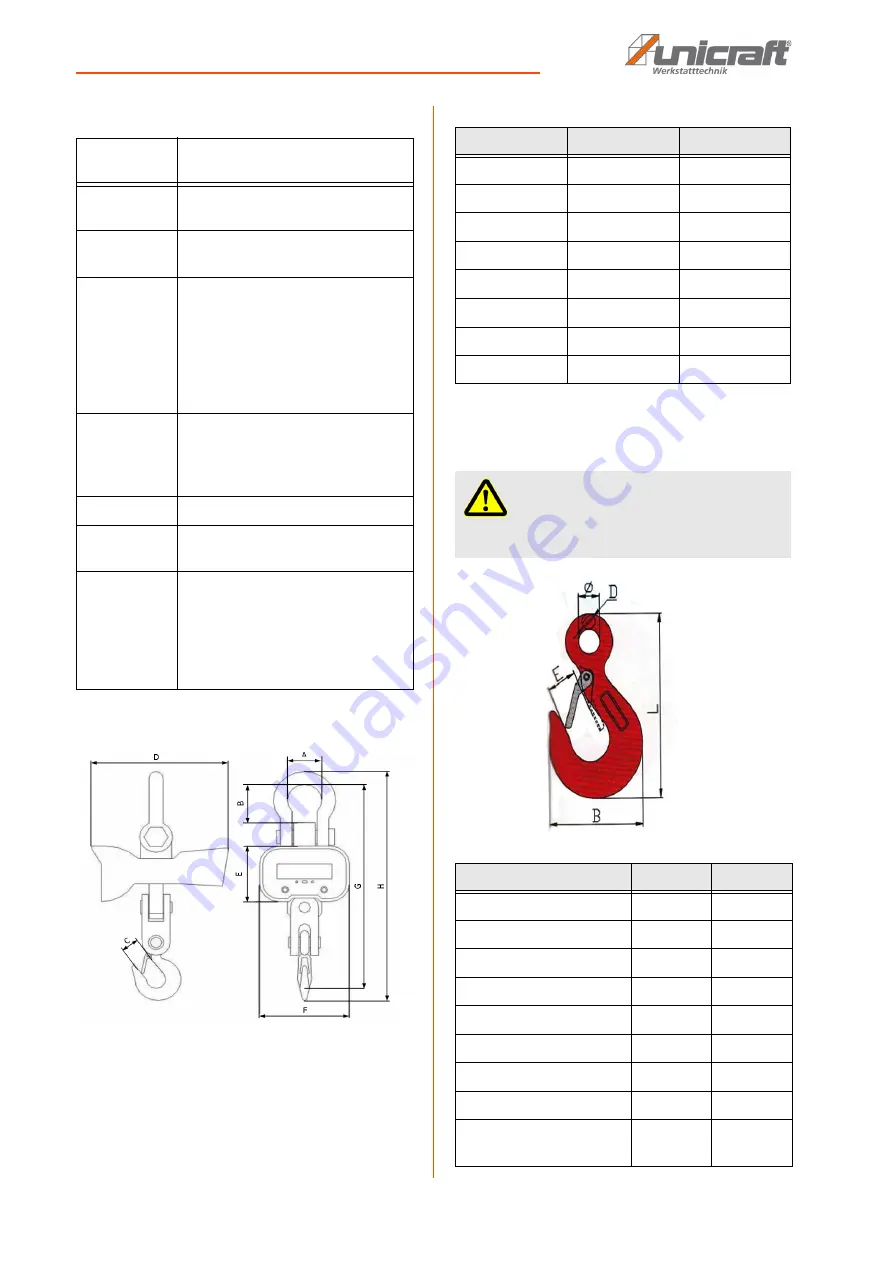

Fig. 5: Dimensions of the Crane scale

In accordance with DIN 15405 Part 1, the load hook and the

lifting eye must be replaced with a widening of more than

10%.

Fig. 6: Hook Dimensions

Maintenance

interval

Maintenance work

Before every

use

Check Crane scale for damage.

Check the battery level before each

use

Regularly inspect the Crane scale,

including lifting eye and load hook for

deformation, cracks or other defects.

If the lifting eye or load hook is bent

or the diameter is more than 10%

worn, replace the lifting eye or the

load hook.

After each

use

Relieve the crane scales immedi-

ately after each use.

Oil the load hook and the lifting eye

well.

40 hours

Lubricate all bearings.

upon need

Replacement of lifting eye and load

hook

yearly

Safety test: If the crane scale is used

in a company, it must be tested an-

nually in accordance with the Ger-

man Industrial Safety Ordinance and

documented in accordance with §

10.

KW

5

10

A [mm]

92

94

B [mm]

135

145

C [mm]

45

60

D [mm]

325

364

E [mm]

155

155

F [mm]

230

230

G [mm]

585

770

H [mm]

650

810

ATTENTION!

Only use original parts from the manufacturer of the

hoist as a replacement.

Model

KW 5

KW 10

Load capacity KW

5 t

10 t

Load capacity hook

7 t

11 t

Length hook L [mm]

255

315

Wide hook B [mm]

184

190

Diameter

Ø

[mm]

51

60,5

Diameter D [mm]

21,5

31

Opening width E [mm]

42,5

60

Safety factor hook

4:1

4:1

Tolerance range dimensi-

ons

+/- 0,5

mm

+/- 0,5

mm