Hydraulic and electrical connection

SHB 3 | Version 1.02

11

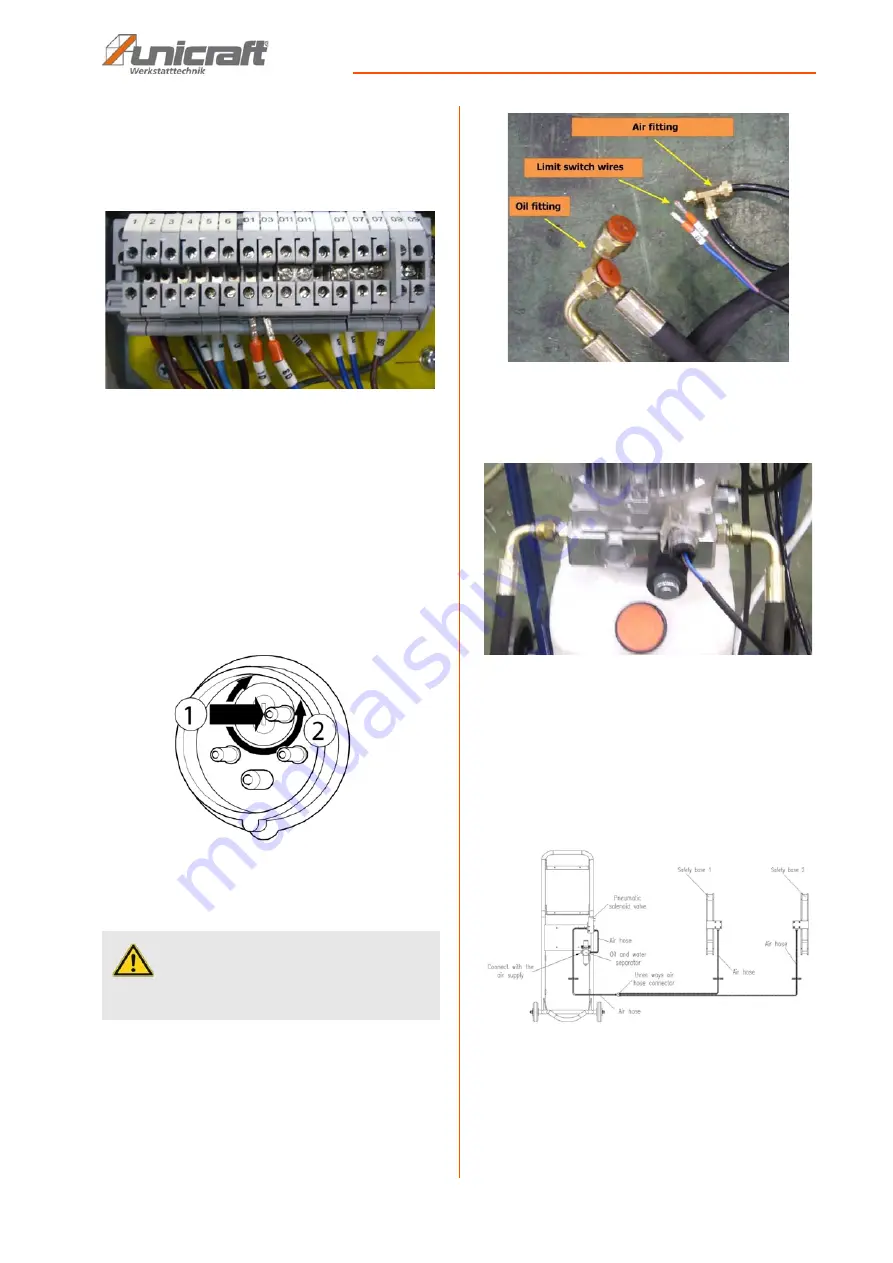

Step 1: Connect the limit switch wiring inside the electri-

cal box as shown in Figure 10.

01 Wiring to 01 Terminal

03 Wiring to 03 Terminal

Fig. 10: Electrical connection

Step 2: Connect the lift to the power supply.

Check motor rotation direction

After electrical connection, check that the direction of

rotation of the motor is correct. If the direction of rotation

is wrong, the connections of the phase lines must be re-

placed.

If equipped with a phase inverter:

Press the disc in the plug with a screwdriver and turn it

by 180°.

Fig. 11: Change motor direction of rotation

8.2 Hydraulic connection

Step 1: Prepare the wires and cables for the lift connec-

tions (Fig.12).

Fig. 12: Hydraulic connection

Step 2: Connect the hydraulic line to the hydraulic

pump. The hoses can be arranged freely on

each side.

Fig. 13: Connection to the hydraulic pump

Step 3: Connect the compressed air (the air pressure

range is between 1.0 and 1.5 kg/cm2 ) to the air

connection of the oil-water separator of the

pump station.

Step 4: Then connect the safety valve to the air outlet of

the pneumatic solenoid valve of the pumping

station.

Fig. 14: Compressed air connection

Step 5: Fill the oil tank with hydraulic oil The distance

between the oil level and the upper edge of the

oil tank should be in the range of 10 to 30 mm.

(Measurement with dipstick on the tank cap)

DANGER!

All work on the hydraulic installation may only be car-

ried out by a qualified person.