Intended use

SHB 3 | Version 1.02

7

2.7 General safety regulations

- Please read this manual carefully before installa-

tion and operation to avoid damage to property and

personal injury due to improper operation.

- Do not work on the machine under the influence of

drugs or alcohol and when you are tired.

- It is not permitted to make any changes to the con-

trol unit or any mechanical unit.

- The lift may only be set up and operated by per-

sons who are familiar with the lift and are aware of

the risks involved in using the lift.

- Do not operate the lift under the influence of drugs,

alcohol or medication.

- The electrical connection may only be carried out

by a qualified electrician.

- Keep the handles dry, clean and free of oil and

grease.

- Keep children and unauthorised personnel away

from the work area.

- Always keep the work area clean and accessible.

- Keep the work area well lit.

- Do not mount the lift on an asphalt surface.

- Read and understand the safety instructions before

operating the lift.

- Before cleaning the machine or carrying out main-

tenance work, switch off the machine and unplug

the power cord.

- Never pull on the mains cable, only on the plug to

disconnect the lift from the mains. Keep the cable

away from heat, oil and sharp edges.

- Never leave the working area while the lift is in ope-

ration.

- Watch your hands and feet when the lift is lowered.

- Always wear the necessary safety equipment (pro-

tective gloves, safety shoes, etc.)

- Never exceed the maximum permitted weight of

the lift.

- Do not rock the vehicle on the lift and do not re-

move heavy components from the vehicle that

could cause excessive weight shift.

- Make sure that all safety precautions are in place

before working near or under the vehicle. Never re-

move safety-relevant components from the lift.

- Do not use the lift if safety-related components are

missing or damaged.

- Lower the lift to its lowest position and disconnect

the power supply.

- Always check the mobility of the lift to ensure per-

formance.

- Ensure regular maintenance. If an irregularity oc-

curs, stop working with the lift immediately and

contact your dealer.

- Only use original UNICRAFT accessories and

spare parts.

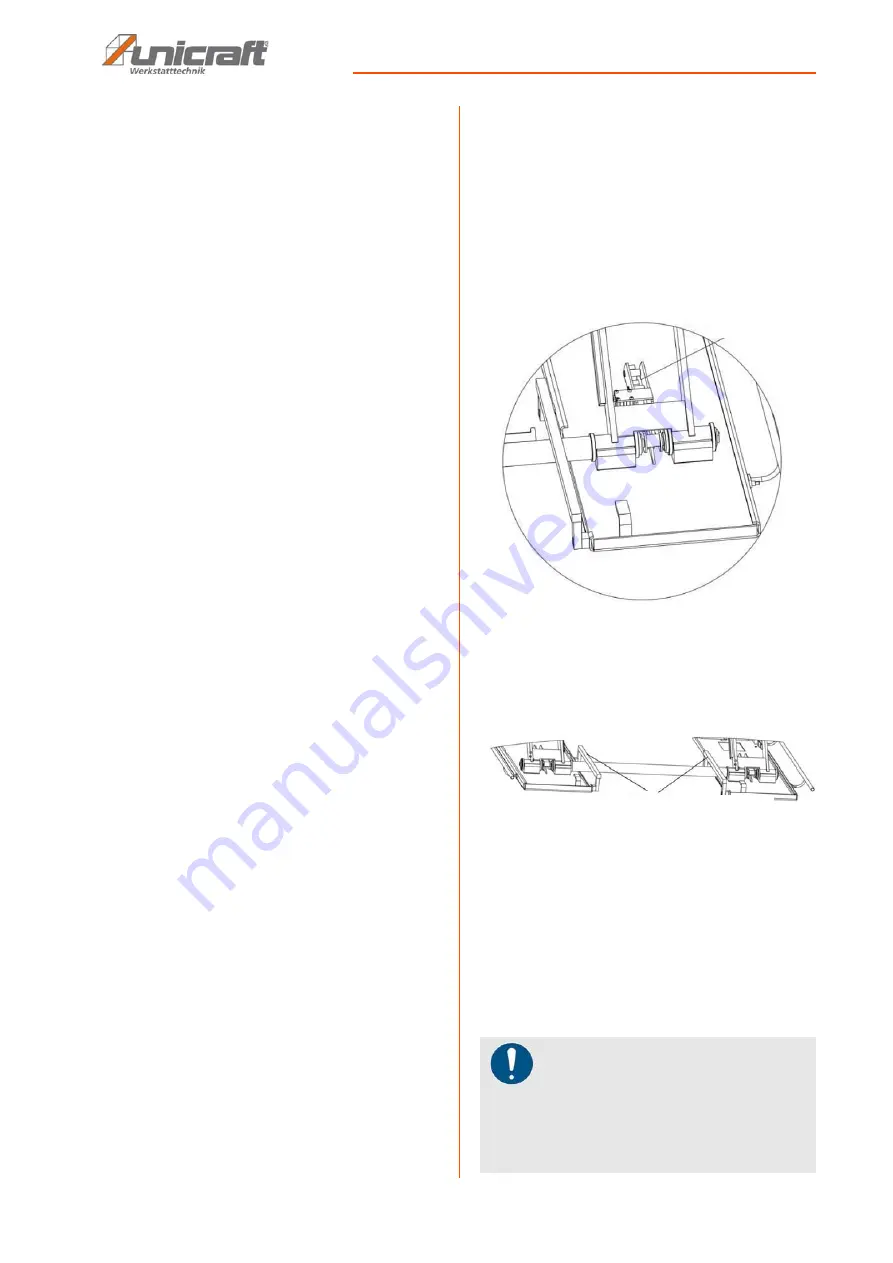

2.8 Safety devices

Integrated in the switch box is a hydraulic power unit

which generates the necessary pressure to lift the vehi-

cle. This is controlled by valves and moves the cylinders

and platforms upwards via the scissor mechanism. Du-

ring the lifting process, the safety catches engage to pre-

vent the platforms from lowering in case of a defect in the

hydraulic system.

Fig. 3: Protection device in case of hydraulic failure

The left as well as the right side of the base plate is fixed

with an anti-tipper. This prevents a possible tipping of the

vehicle.

Fig. 4: Device for protection against tipping

3 Intended use

The scissor lift is used exclusively for lifting and lowering

loads, e.g. vehicles, up to the specified maximum load.

Proper use also includes compliance with all the informa-

tion in these instructions. Any use beyond the intended

use or any other use is considered misuse.

NOTE!

The improper use (misuse) of the lift as well as the

disregard of the safety regulations or the operating

instructions exclude any liability of the manufacturer

for resulting damages to persons or objects and

cause the warranty to expire!

Mechanical

Safety Lock

Protection against tipping