Transport, packaging, storage

WPP 15 E | Version 1.02

7

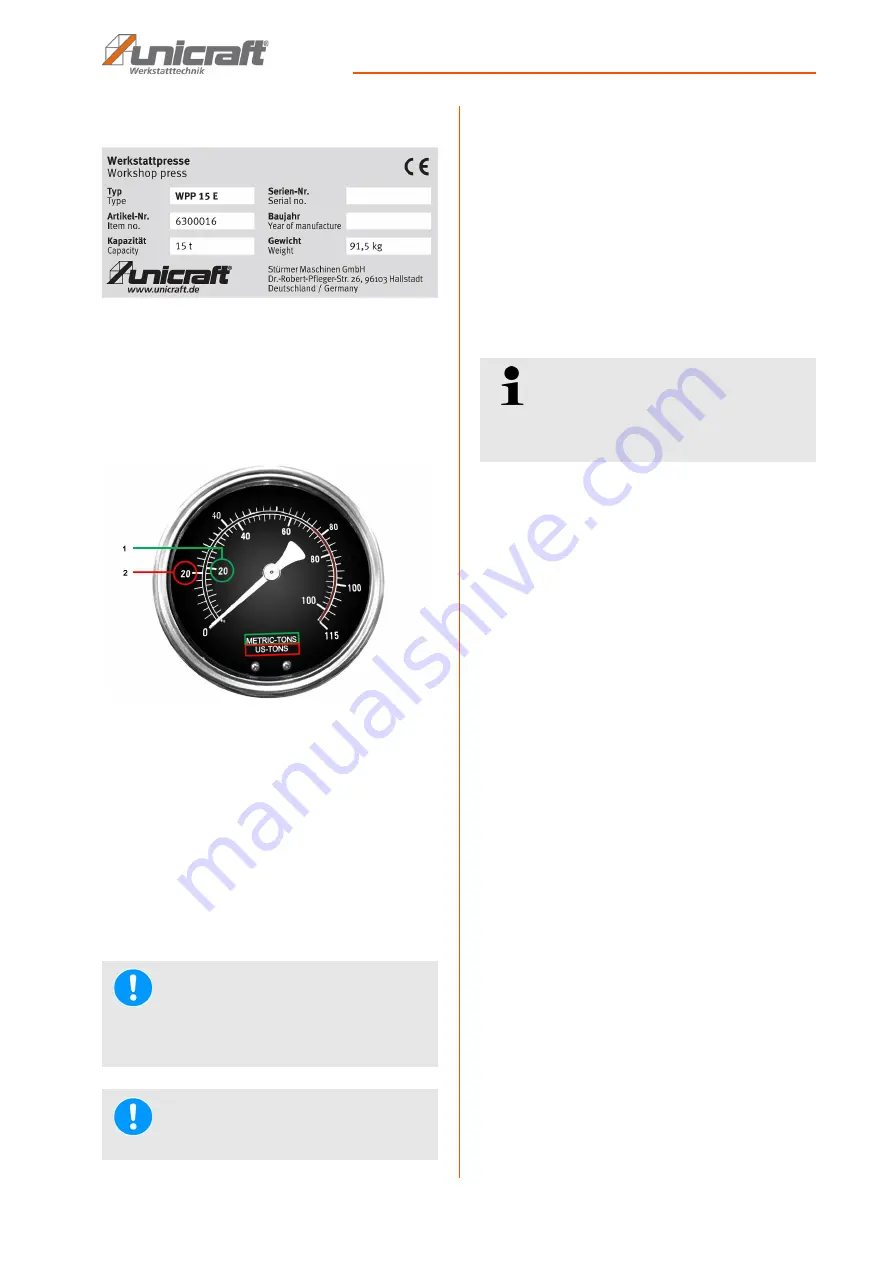

4.3 Type plate

Fig. 2: Type plate of the WPP 15 E hydraulic workshop press

4.4 Pressure gauge

The pressure gauge used features two scales:

- Outer scale [1] shows US tons [1tn. sh.=907.18 kg]

- Inner scale [2] shows metric tons

[1 t = 1000 kg], usual throughout Europe

Fig. 3: Pressure gauge

5 Transport, packaging, storage

Delivery

Check the hydraulic workshop press for visible transport

damage upon delivery. Immediately notify the haulage

company or retailer if you identify damage on the hy-

draulic workshop press.

Transport

The hydraulic workshop press must be transported up-

right only. Do not stack hydraulic workshop presses on

top of each other. Do not place any other objects onto

workshop presses.

Secure the upright hydraulic workshop press on a pallet

using bolts. Said pallet must be correctly secured in the

cargo area. Any loose parts must be securely fastened

to the hydraulic workshop press, secured separately or

safely stored in a separate container.

Blank metal parts have been greased to protect them

from humidity and dirt.

Transport using industrial trucks/pallet trucks:

The hydraulic workshop press must be positioned on an

even, stable surface (e.g. a pallet) and be secured with

bolts in the event of transport using a suitably dimen-

sioned pallet truck or industrial truck.

Packaging

All packaging materials and packing aids used for the

hydraulic workshop press are suitable for recycling and

must always be disposed of using material-based recy-

cling systems.

Packaging materials made of cardboard must be shred-

ded and disposed of as part of waste paper recycling.

The foils are made of polyethylene (PE), padding is

made of polystyrene (PS). Dispose of these substances

at a recycling centre or hand them over to the relevant

waste disposal company.

Storage

As a rule, the hydraulic workshop press must be stored

in a clean condition and a dry, clean and frost-free envi-

ronment. The pistons must be fully retracted.

NOTE!

Take into account the weight of the machine when

transporting and lifting it. Transport and hoisting

equipment must be able to carry the load.

NOTE!

Protect the machine from humidity.

Tips and recommendations

Make sure the corrosion protection is active or

replaced (if necessary) in the event of prolonged

transport.